HEI150 Wood Insert Fireplace Installation and Operation Manual

26

PART B - INSTALLATION

6 Pre-Installation Masonry fireplace requirements

The masonry fireplace must meet the minimum requirements found in the building code

enforced locally, or the equivalent for a safe installation. Contact your local Building

Inspector for requirements in your area. An inspection of the fireplace should include the

following:

1.

CONDITION OF THE FIREPLACE AND CHIMNEY

:

The masonry fireplace and chimney should be inspected prior to installation, to determine

that they are free from cracks, loose mortar, creosote deposits, blockage, or other signs

of deterioration. If evidence of deterioration is noted, the fireplace or chimney should be

upgraded and/or cleaned prior to installation.

Masonry or steel, including the damper plate, may be removed from the smoke shelf and

adjacent damper frame if necessary to accommodate the insert’s chimney liner, provided

that their removal will not weaken the structure of the fireplace and chimney, and will not

reduce protection for combustible materials to less than that required by the building

code.

2. INSTALLATION INTO AN EXISTING FACTORY-BUILT ZERO-CLEARANCE FIREPLACE:

It is possible to install a wood insert into an existing factory-built zero-clearance fireplace.

However, there currently exists no UL or ULC standard specific to that type of installation.

The factory-built zero clearance fireplace must be listed; that is, safety certified by an

accredited certification agency such as UL/ULC, Omni or Intertek). It must be suitable

for use with solid fuel and nothing in the owner’s manual must specifically prohibit the

installation of a fireplace insert. When in doubt, check with the fireplace manufacturer.

The installation of the zero-clearance fireplace MUST be thoroughly inspected by a

qualified person to ensure that it still meets the manufacturer’s specifications. The

chimney must be at least 1" (25 mm) larger in diameter than the stainless steel liner that

will run from the insert flue collar to the top of the chimney termination.

Never remove parts intended to insulate the zero-clearance fireplace from combustible

material. Only readily detachable parts that are easily replaced, such as damper parts,

screens, and doors, are to be removed from the fireplace. These parts should be stored

and available for reinstallation if the insert is ever removed. Removal of any parts which

render the fireplace unfit for use with solid fuel requires the fireplace to be permanently

labeled by the installer as being no longer suitable for solid fuel until the removed parts

are replaced and the fireplace is restored to its original certified condition. Also, any air

vents, grilles, or louvers that allow air circulation around the fireplace must not be

removed or blocked.

3. CHIMNEY CAPS:

Mesh type chimney caps must have provision for regular cleaning, or the mesh should

be removed to eliminate the potential of plugging.

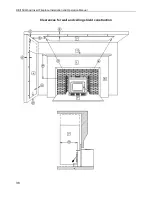

4. ADJACENT COMBUSTIBLES:

The fireplace should be inspected to make sure that there is adequate clearance to

combustibles, both exposed combustibles to the top, side, and front as well as concealed

combustibles, in the chimney and mantle area. Your local inspector should have

information on whether older fireplaces are of adequate construction.

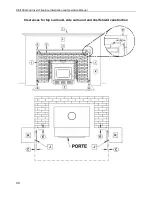

5. OPENING SIZE:

Refer to “Minimum masonry opening” (Section 8.5) for suitable size fireplace

openings.