HEI150 Wood Insert Fireplace Installation and Operation Manual

33

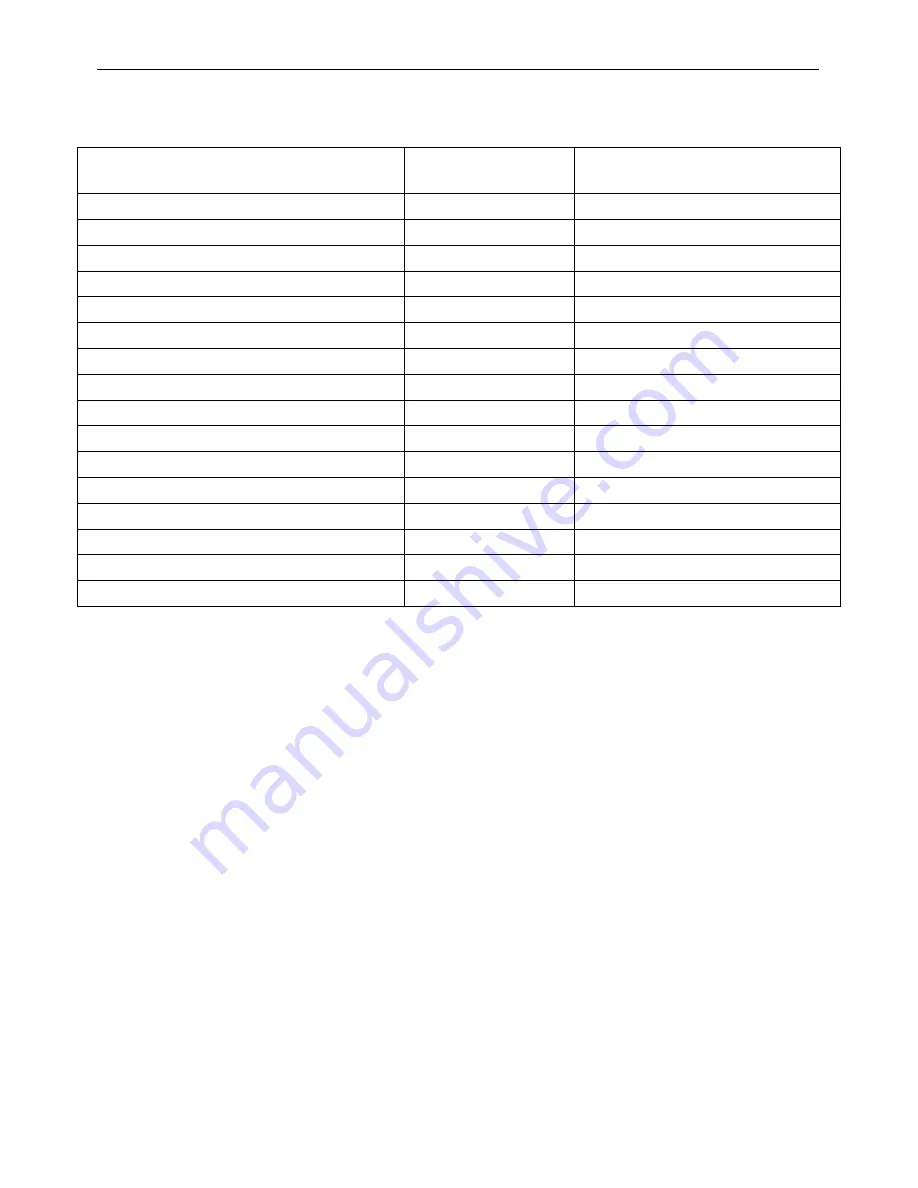

Thermal Characteristics of Common Floor Protection Materials*

MATERIAL

CONDUCTIVITY (k)

PER INCH

RESISTANCE (R) PER INCH

THICKNESS

Micore

®

160

0.39

2.54

Micore

®

300

0.49

2.06

Durock

®

1.92

0.52

Hardibacker

®

1.95

0.51

Hardibacker

®

500

2.3

0.44

Wonderboard

®

3.23

0.31

Cement mortar

5.00

0.2

Common brick

5.00

0.2

Face brick

9.00

0.11

Marble

14.3 – 20.00

0.07 – 0.05

Ceramic tile

12.5

0.008

Concrete

1.050

0.950

Mineral wool insulation

0.320

3.120

Limestone

6.5

0.153

Ceramic board (Fibremax)

0.450

2.2

Horizontal still air** (1/8")

0.135

0,920**

* Information as reported by manufacturers and other resources

** For a 1/8" thickness. You cannot «stack» horizontal still air to accumulate R-values; you must separate each

layer of horizontal still air with another non-combustible material.

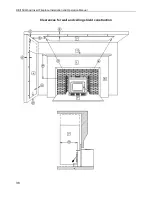

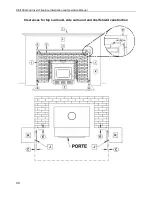

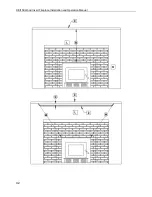

The insert can extend at most 5 1/8" (130 mm) in the room (see illustrations below). The

insert can be moved back this much or to any position in between as long as the openings on

each sides of the insert (A) are always in front of the faceplate. The position chosen will

depend on your own preference for most installations, your current configuration, the

compliance with the preceding installation instructions and compliance with the building code

requirements. To determine the minimum and maximum projection of the insert, refer to table

Data for floor protection calculation.