Page 37

Installation and Operation Manual - HEI170

ENGLISH

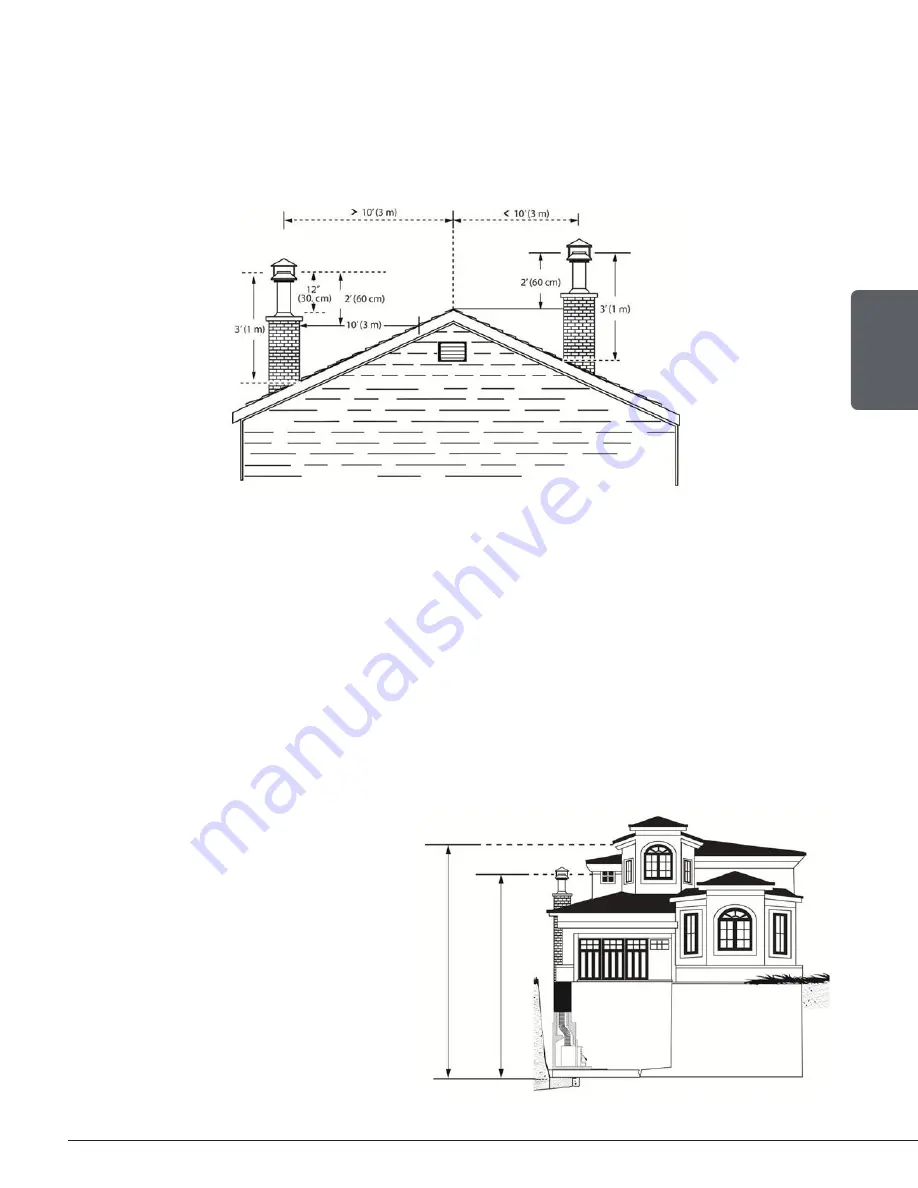

10.6 Minimum Chimney Height

The top of the chimney should be tall enough to be above the air turbulence caused when

wind blows against the house and its roof. The chimney must extend at least 3 ft. (1 m) above

the highest point of contact with the roof, and at least 2 ft.(60 cm) higher than any roof line or

obstacle within a horizontal distance of 10 ft. (3 m).

10.7 Chimney Location

Because the venting system is the engine that drives the wood heating system, it must have the

right characteristics. The signs of bad system design are cold back drafting when there is no fire

in the insert, slow kindling of new fires, and smoke roll-out when the door is open for loading.

When it is cold outside, the warm air in the house is buoyant so it tends to rise. This creates

a slight pressure difference in the house. Called ‘stack effect’, it produces a slightly negative

pressure in the lower part of the house (compared to the outside) and a slightly positive pressure

zone in the high part of the house. If there is no fire burning in a heater connected to a chimney

that is shorter than the warm space inside the house, the slight negative pressure in the lower

part of the house will compete against the desired upward flow in the chimney. This occurs for

the two following reasons:

First, the chimney runs up the outside of

the house, so the air in it is colder and

denser than the warm air in the house.

And second, the chimney is shorter than

the heated space of the house, meaning

the negative pressure in the lower part

of the house will draw cold air down the

chimney, through the insert and into the

room. Even the finest insert will not work

well when connected to this chimney.

Chimney location in the house

Summary of Contents for HEI170

Page 2: ......

Page 6: ...Page 6 Installation and Operation Manual HEI170 ENGLISH CERTIFICATION PLATE ...

Page 51: ......