SERVICE

Service - 40

14. Remove the pump drive belt cover.

15. Disengage the pump belt tension spring.

16. Open the left door.

17. Remove the pump belt from the pump drive pulley.

18. Remove the pump belt from the engine pulley

and pull down over the PTO clutch (if equipped)

to remove.

19. Install the new pump belt onto the engine pulley

and pump pulley.

20. Ensure the belt is properly seated in the pulleys

and engage the belt tension spring.

21. If the power unit is not equipped with a PTO kit,

skip to step 27.

22. Reinstall the clutch torque bracket onto the

engine mount frame. Make sure the anti-rotation

bolt on the clutch is located between the rubber

bumpers on the clutch torque bracket. Torque

bolts to 210 in-lbs (24 Nm).

23. Reconnect the PTO wire harness to the clutch.

24. Reinstall the PTO belt onto the clutch pulley.

25. Use a 3/8” drive ratchet to rotate the PTO belt

tension arm far enough to install the belt onto

the belt tension pulley.

26. Reinstall the PTO belt cover and the PTO drive

cover. Torque the bolts to 100 in-lbs (11 Nm).

27. Reinstall the center fender platform and torque

the bolts to 210 in-lbs (24 Nm).

28. Reinstall the left, right, and front engine covers

and torque the bolts to 100 in-lbs (11 Nm).

29. Reinstall the pump belt drive cover and torque

the bolts to 100 in-lbs (11 Nm).

30. Reinstall the operator cushion.

31. Close the left door.

PTO Drive Belt Replacement

1. Park the power unit on a level surface.

2. Engage the parking brake and shut off the engine.

3. Remove the key from the ignition switch.

4. Remove the PTO drive cover.

5. Remove the front, left, and right engine covers.

6. Remove the PTO belt cover.

7. Use a 3/8” drive ratchet to rotate the PTO belt

tension arm far enough to remove the belt from

the belt tension pulley.

8. Remove the PTO belt from the clutch pulley. Pull

the belt end down around the clutch body, then

pull forward and up between the clutch torque

bracket and the power unit frame.

9. Remove the belt from the front idler pulleys.

10. Install the new belt by sliding one end of the belt

down through the main frame in front of the clutch

torque bracket. Pull the end back underneath the

bracket and install onto the clutch pulley.

11. Route the belt forward to the idler pulleys. Twist

the belt so the left side of the belt lays in the

v-idler pulley and the back of the right side of the

belt lays against the flat idler pulley.

12. Use a 3/8” drive ratchet to rotate the PTO belt

tension arm far enough to install the belt onto

the double idler pulley. Position in the groove next

to the pulley mounting bracket.

13. Reinstall the PTO belt cover and the PTO drive

cover. Torque the bolts to 100 in-lbs (11 Nm).

14. Reinstall the left, right, and front engine covers

and torque the bolts to 100 in-lbs (11 Nm).

Wheel Removal & Installation

Wheel Removal:

1. Park the power unit on a level surface.

2. Engage the parking brake and shut off the engine.

3. Remove the key from the ignition switch.

4. Loosen the wheel lug nuts, but do not remove.

5. Lift up the power unit to raise the wheel off the

ground and secure with a jack stand.

6. Remove the lug nuts and lift the wheel off the

mounting studs.

Wheel Installation:

1. Place the wheel onto the mounting studs with

the hub side of the rim against the motor hub.

NOTE: the valve stem will be to the outside of

the power unit.

2.

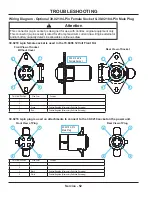

1

3

4

2

Install the lug nuts and tighten by hand until the

wheel is held against the axle hub.

3. Lift the power unit up slightly

and remove the jack stand.

Lower the power unit to the

ground.

4. Tighten the wheel nuts in

a crisscross sequence as

shown. Torque to 85 ft-lbs

(115 Nm).

Tire Pressure

Maintain tire pressure at 18 psi (124 kPa). Check

the tire pressure prior to operation, as part of the

daily inspection. Keep tires evenly inflated. Keep

tires inflated to the proper pressure to prevent pre-

mature wear and/or poor traction.