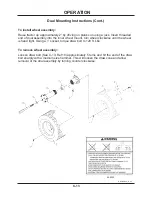

Figure 36

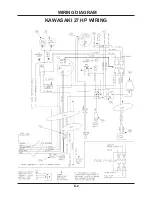

Figure 37

D-3

SERVICE & MAINTENANCE

AIR INTAKE FILTER

The air intake filter on the Vanguard engine

models is located on the left side

(Figure 36)

. This

external filter assembly has 4 stages of filtration.

1

) An intake turbo.

2

) A dust unloading valve. (1 &

2 require no servicing.)

3

) A prefilter.

4

) a final

cylinder element.

Note:

Under normal operating conditions, the

inner filter does not need be replaced. Never

operate with inner filter removed.

Kawasaki engine air intake filters are located

above the engine and have a prefilter band over a

paper element. The paper element should be

changed if its appearance is dirty or light is no

longer visible through the element when held up to

a light source. See engine manual for more

details.

Note:

Kawasaki does not recommend oiling the

foam prefilter (outer) element.

Expansion tank

HYDROSTATIC TRANSMISSION OIL

The top oil reservoir for the hydrostatic

transmission oil is located under the hood near the

right side of the dash. Check oil level when engine

is cold. Find the oil level in the plastic sight tube

next to the expansion tank, and check that it is

within the proper range indicated by the oil level

decal. This is important for proper performance

and life of the hydrostatic system.

NOTE:

Non-compliance to this specification may void

the VENTRAC 4200 VXD warranty.

Note: Generally the hydrostatic oil level

remains constant except when:

1) New attachments are added that use

the auxiliary oil circuit.

2) There is an oil leak.

NOTE: Changing of hydrostatic oil is Not

recommended except in the event of

excessive contamination.

Plastic sight tube

Oil level decal

REQUIRED OIL

SPECIFICATION

Ventrac Hydro•Torq XL

synthetic hydraulic oil

System Capacity: Front - 12 quarts

Rear - 4 quarts