PARTS

Illustrated Parts - 32

Use only original Ventrac

replacement parts.

ILLUSTRATED DRAWING

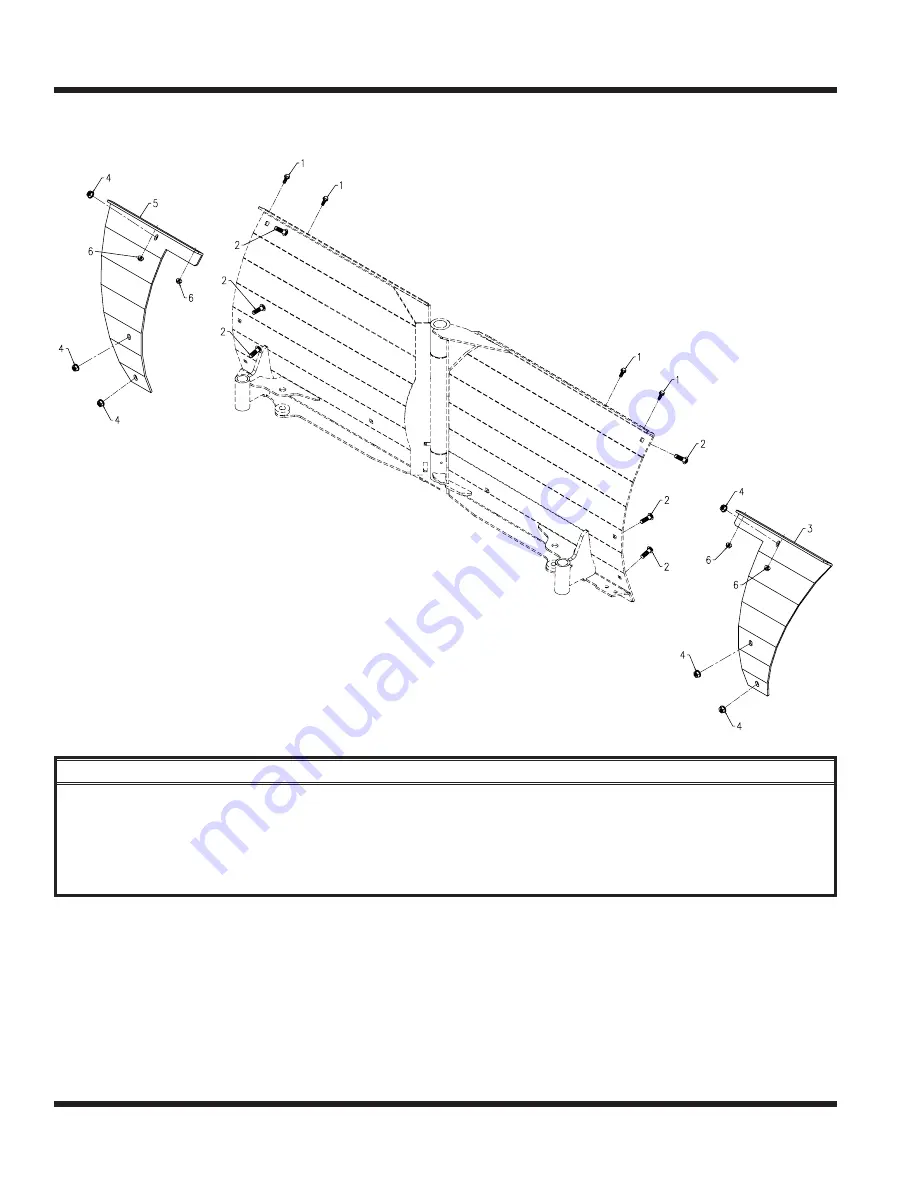

70.8045 6” Top Flare Extension

REF.

PART NO.

DESCRIPTION

QTY.

1 . . . . . . . . . 99.SF0406 . . . . . . . . . . . . . . . . .BOLT, SRF 1/4-20 X 3/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 . . . . . . . . . 97.0608 . . . . . . . . . . . . . . . . . . . .BOLT, CARRIAGE 3/8 X 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 . . . . . . . . . 60.0889 . . . . . . . . . . . . . . . . . . . .EXTENSION, FLARE RH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 . . . . . . . . . 99.SF06 . . . . . . . . . . . . . . . . . . .NUT, SRF 3/8-16 USS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 . . . . . . . . . 60.0890 . . . . . . . . . . . . . . . . . . . .EXTENSION, FLARE LH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6 . . . . . . . . . 99.SF04 . . . . . . . . . . . . . . . . . . .NUT, SRF 1/4-20 USS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4