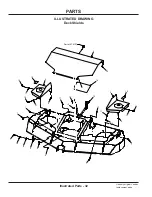

PARTS

Illustrated Parts - 33

Use only original Ventrac

replacement parts.

Deck Shields

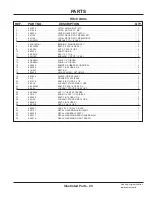

REF. PART

NO.

DESCRIPTION

QTY.

1 . . . . . . . . . 99.E0046 . . . . . . . . . . . . . . . . . . .NUT, “U” 1/4-20 EXTRUDED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 . . . . . . . . . 60.0895 . . . . . . . . . . . . . . . . . . . .SHIELD, RIGHT SPINDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 . . . . . . . . . 60.0896 . . . . . . . . . . . . . . . . . . . .SHIELD, LEFT SPINDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 . . . . . . . . . 60.0894 . . . . . . . . . . . . . . . . . . . .SHIELD, MAIN DECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5 . . . . . . . . . 05.0062 . . . . . . . . . . . . . . . . . . . .BUMPER, NEOPRENE 18-12 GA, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6 . . . . . . . . . 99.SF06 . . . . . . . . . . . . . . . . . . . .NUT, SF 3/8-16 USS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7 . . . . . . . . . 90.0612 . . . . . . . . . . . . . . . . . . . .BOLT, 3/8-16 USS X 1 1/2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

8 . . . . . . . . . 41.0039 . . . . . . . . . . . . . . . . . . . .SPRING, COMP. 9/16 OD X 5/8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9 . . . . . . . . . 64.1154 . . . . . . . . . . . . . . . . . . . .BRACKET, MAIN SHIELD LATCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

10 . . . . . . . . 95.06 . . . . . . . . . . . . . . . . . . . . . .WASHER, FLAT 3/8 SAE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

11 . . . . . . . . . 95.04 . . . . . . . . . . . . . . . . . . . . . .WASHER, FLAT 1/4 SAE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

12 . . . . . . . . 47.0127 . . . . . . . . . . . . . . . . . . . .LATCH, RUBBER DRAW T-HANDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

13 . . . . . . . . 99.K0072 . . . . . . . . . . . . . . . . . . .MACHINE SCREW, 10-24 X 1/2 ZP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

14 . . . . . . . . 90.0406 . . . . . . . . . . . . . . . . . . . .BOLT, 1/4-20 USS X 3/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

15 . . . . . . . . 00.0218 . . . . . . . . . . . . . . . . . . . .DECAL, WARNING PINCH POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

16 . . . . . . . . 00.0258 . . . . . . . . . . . . . . . . . . . .DECAL, MAINTENANCE MC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

17 . . . . . . . . 05.0120 . . . . . . . . . . . . . . . . . . . .BUMPER, NEOPRENE 10 GA - 1/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2