Summary of Contents for VR300

Page 7: ...Safety Decal Locations SAFETY B 3 ...

Page 19: ...Electrical Schematic MAINTENANCE D 6 ...

Page 20: ...PARTS E 1 ILLUSTRATED DRAWING CHAIR COMPARTMENT ...

Page 22: ...PARTS E 3 ILLUSTRATED DRAWING TAILGATE MECHANISM ...

Page 24: ...PARTS E 5 ILLUSTRATED DRAWING BRAKE MECHANISM ...

Page 26: ...PARTS E 7 ILLUSTRATED DRAWING PUMP CONTROLS ...

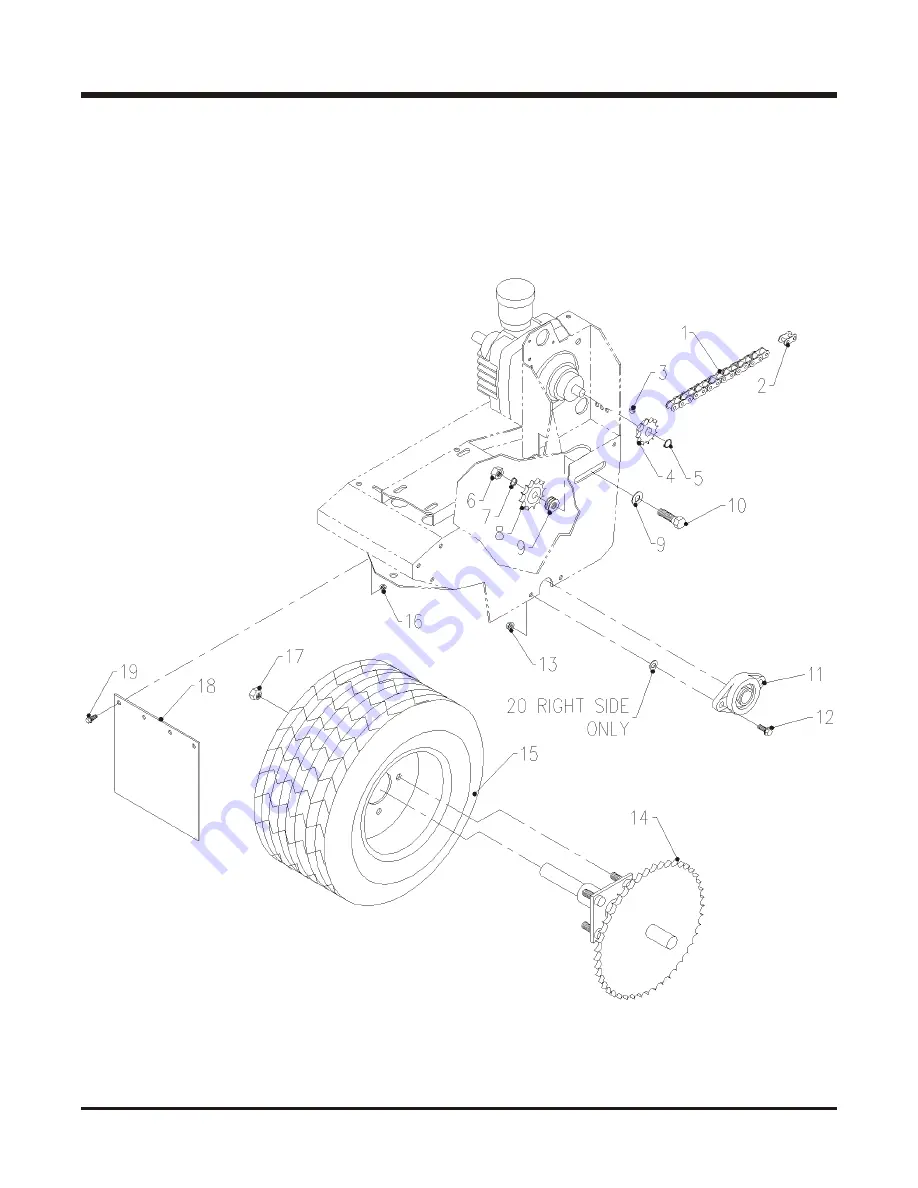

Page 28: ...PARTS E 9 ILLUSTRATED DRAWING DRIVE WHEEL ...

Page 30: ...PARTS E 11 ILLUSTRATED DRAWING ENGINE ...

Page 32: ...PARTS E 13 ILLUSTRATED DRAWING HANDLE BAR CONTROLS ...

Page 34: ...PARTS E 15 ILLUSTRATED DRAWING COAST LEVER ELECTRICAL PARTS ...

Page 36: ...PARTS E 17 ILLUSTRATED DRAWING SHIELDS BATTERY ...

Page 38: ...PARTS F 1 ILLUSTRATED DRAWING GUN RACK ...

Page 40: ...PARTS F 3 ILLUSTRATED DRAWING BRAKE LEVER EXTENSION ...

Page 42: ...PARTS F 5 ILLUSTRATED DRAWING RAMP TAILGATE LEVER EXTENSION ...

Page 44: ...PARTS F 7 ILLUSTRATED DRAWING TACHOMETER HOUR METER ...