The unit is designed for indoor application with the ambient temperature ranging from 32 °F up +113 °F °C and relative humidity up

to 80 %.

The unit is rated as a Class I electrical appliance. Hazardous parts access and water ingress protection rating: IP22 for the assembled unit

connected to the air ducts and IP44 for the unit motors.

The unit design is constantly being improved, thus some models may be slightly different from those described in this manual.

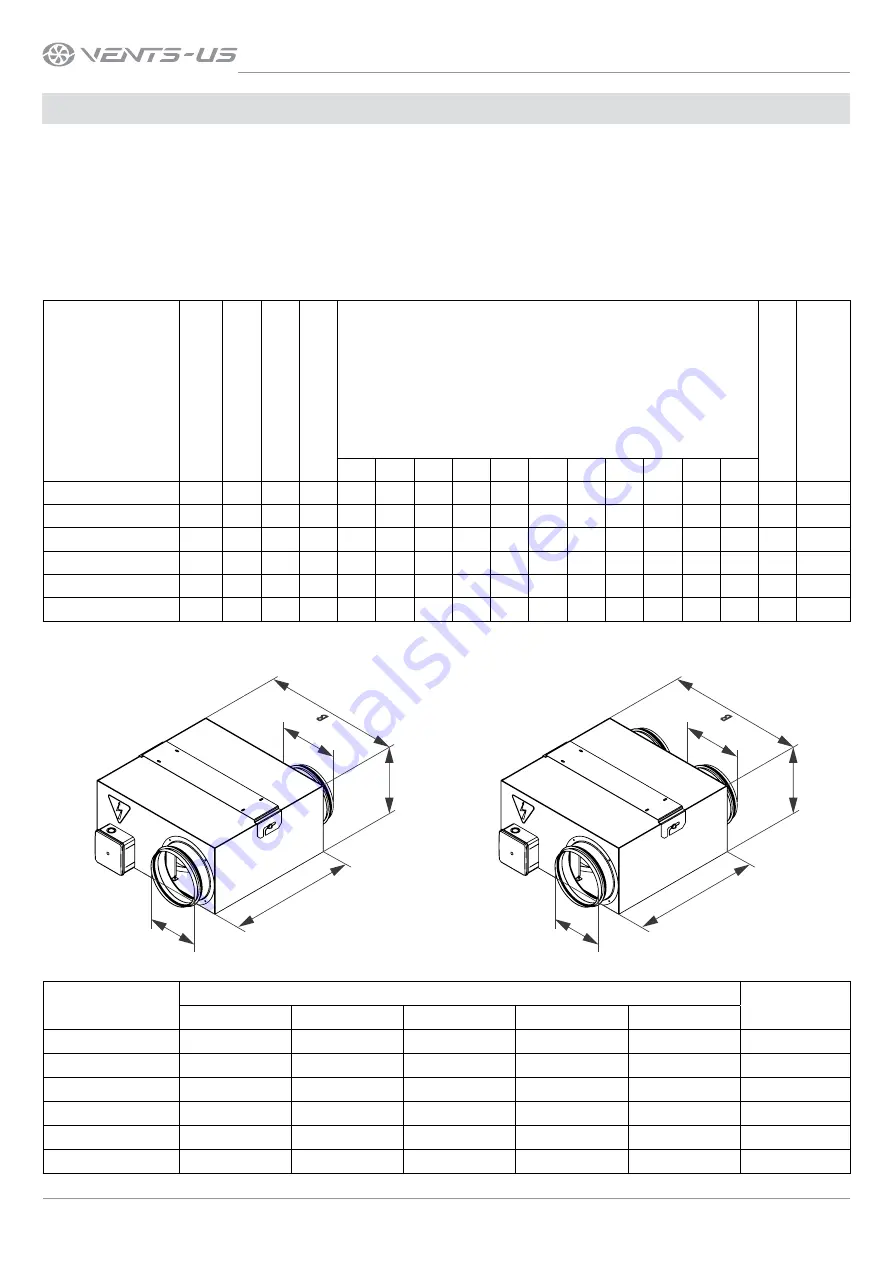

TECHNICAL DATA

Air flow capacity: up to 360 CFM

Power consumption: 30-119 W

Sound level: 3.7–4.5 Sones

Model

Duc

t Dia.

W

atts*

Amps*

Sones @10 f

t

CFM vs. Staic Pressure [Ps] in.W.G.

M

ax. P

s

Volt/H

z

0”

0.1” 0.2” 0.3” 0.4” 0.5” 0.6” 0.7” 0.8” 0.9” 1”

VKP 100

4"

30

0.27 3.7

104 98

94

89

84

77

69

61

52

43

33

1.2

120/60

VKP 125

5"

66

0.54 4.2

220 214 208 202 196 190 184 178 172 160 150 2.4

120/60

VKP 125/125x2

5"/5" 74

0.61 4.2

244 234 223 213 204 194 183 170 160 150 140 1.9

120/60

VKP 150

6"

101 0.82 4.5

300 292 283 274 266 257 248 238 229 219 210 3.0

120/60

VKP 150/150x2

6”/6” 119 1

4.5

360 348 332 316 302 289 272 259 245 323 220 3.0

120/60

VKPF 125/125x2

5”/5” 80

0.68 3.5

267 256 246 234 216 195 177 152 55

0.84 120/60

* The parameters Watts, Amps are stated in 0.2” in.W.G. Static Pressure.

Model

Measurements [in.]

Picture

Ø D

Ø D1

L

B

H

VKP 100

4”

4”

13 7/8”

9 7/8”

6 3/8”

1

VKP 125

5”

5”

16 3/16”

12 3/16”

7 1/2”

1

VKP 150

6”

6”

18 3/16”

15 7/16”

7 1/2”

1

VKP 125/125x2

5”

5”

16 3/16”

12 3/16”

7 1/2”

2

VKP 150/150x2

6”

6”

18 3/16”

15 7/16”

7 1/2”

2

VKPF 125/125x2

5”

5”

10 5/8”

11 7/64”

7 31/64”

2

L

H

D

D1

H

L

D

D1

Pic. 1 Inline dryer booster fan

Pic. 2 Twin intake fan

VKP / VKPF

6

vents-us.com

Summary of Contents for VKP 100

Page 1: ...USER S MANUAL Inline centrifugal fan VKP VKPF...

Page 16: ...VUSA17EN 06...