9

www.ventilation-system.com

TECHNICAL MAINTENANCE

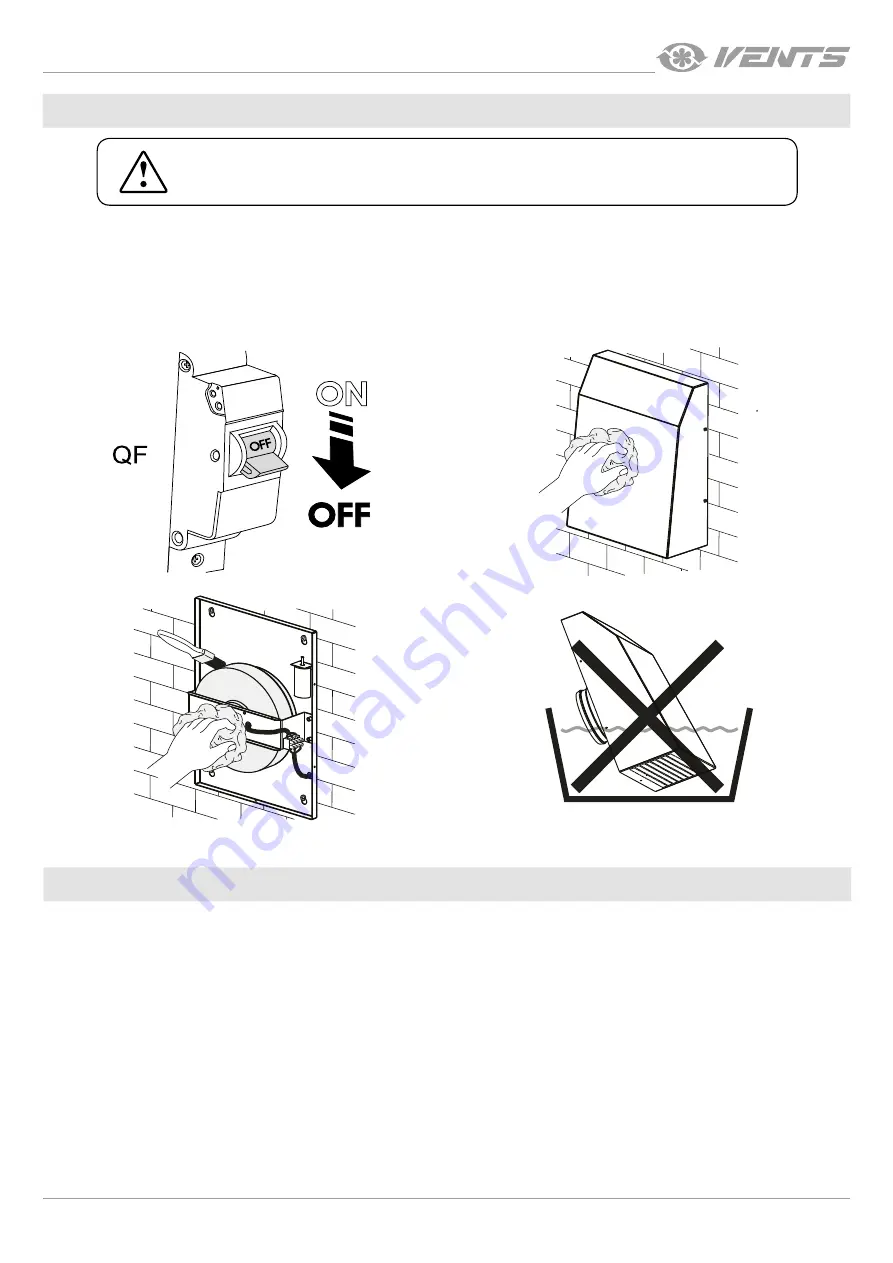

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE

ANY MAINTENANCE OPERATIONS!

Maintenance means regular cleaning of the fan surfaces from dust and dirt. Use a soft dry brush or a vacuum cleaner to remove dust.

The blades require thorough cleaning once in 6 months.

The filter prevents the fan soiling and reduces the cleaning periodicity. To clean the fan undo the self-tapping screws and remove the

fan cover. Clean the impeller blades with a cloth wetted in water and mild detergent solution. Avoid liquid dripping on the motor! After

cleaning the impeller, install the cover back and tighten the screws.

STORAGE AND TRANSPORTATION REGULATIONS

• Store the unit in the manufacturer’s original packaging box in a dry closed ventilated premise with temperature range

+5 ˚...+40 ˚С and relative humidity up to 70 %.

• Storage environment must not contain aggressive vapours and chemical mixtures provoking corrosion, insulation, and sealing

deformation.

• Use suitable hoist machinery for handling and storage operations to prevent possible damage to the unit.

• Follow the handling requirements applicable for the particular type of cargo.

• The unit can be carried in the original packaging by any mode of transport provided proper protection against precipitation and

mechanical damage. The unit must be transported only in the working position.

• Avoid sharp blows, scratches, or rough handling during loading and unloading.

• Prior to the initial power-up after transportation at low temperatures allow the unit to warm up at room temperature for at least

3-4 hours.

Summary of Contents for VCN 100

Page 12: ...V06EN 04 ...