8

VK VMS

www.ventilation-system.com

1

2

3

4

5

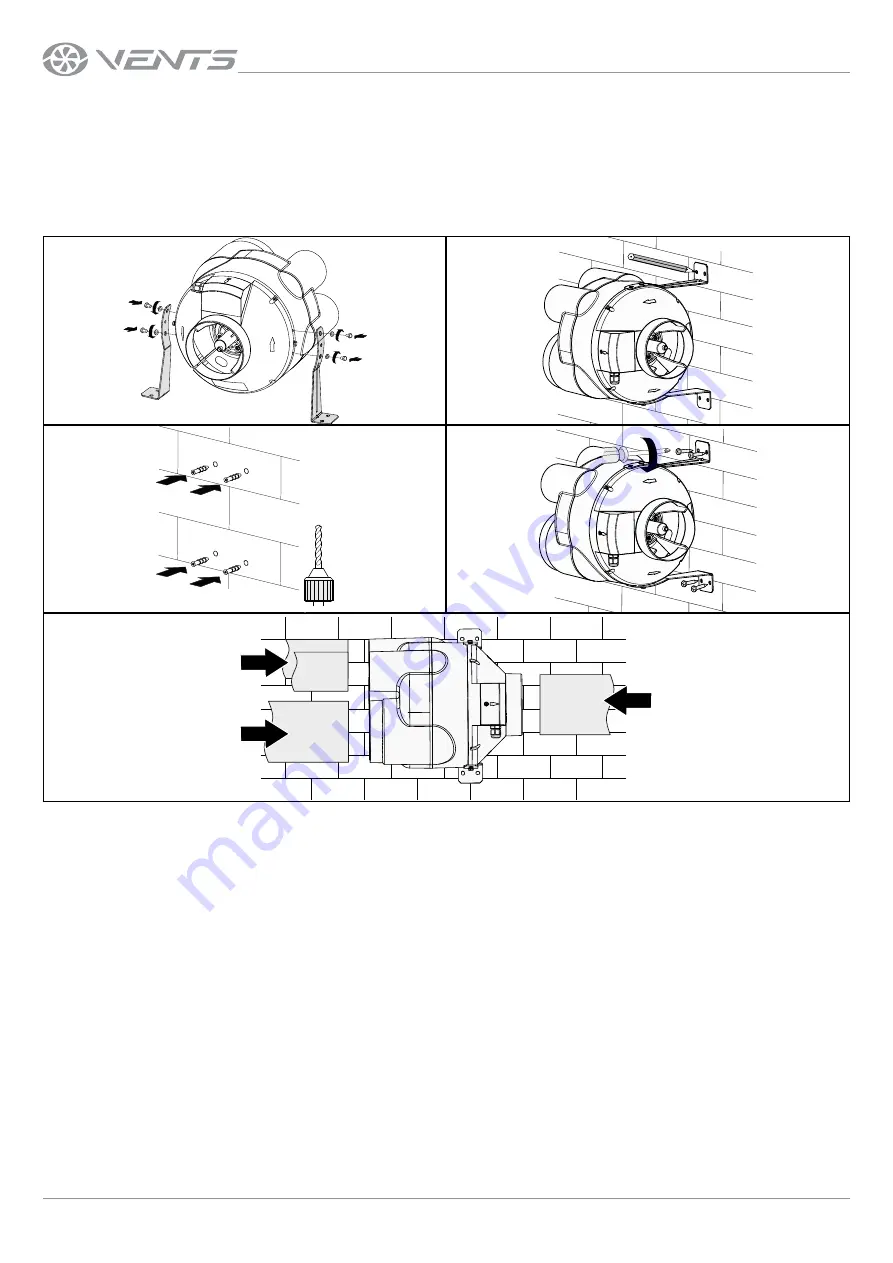

Mounting sequence

1. Remove the bolts on both sides of the casing, install the mounting brackets and tighten the bolts, aligning the holes in the brackets

with the holes in the casing.

2. Mark the drilling holes.

3. Drill the holes in the wall or the ceiling for dowels.

4. Fix the fan with the screws.

5. Connect the air ducts of the corresponding diameter to the fan.

Summary of Contents for VK VMS

Page 1: ...VK VMS Multi zone centrifugal fan USER S MANUAL ...

Page 13: ...13 www ventilation system com ...

Page 14: ...14 VK VMS www ventilation system com ...

Page 15: ...15 www ventilation system com ...

Page 16: ...V193EN 01 ...