10

VUE P3B EС

www.ventilation-system.com

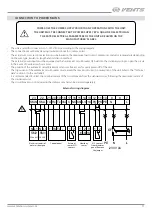

MOUNTING AND SET-UP

READ THE USER'S MANUAL BEFORE INSTALLING THE UNIT.

WHILE INSTALLING THE UNIT ENSURE CONVENIENT ACCESS FOR SUBSEQUENT

MAINTENANCE AND REPAIR.

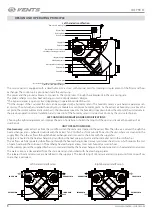

HUMIDITY SENSOR MOUNTING

The humidity sensor is not included in the delivery set and can be ordered separately.

The humidity sensor must be installed prior to unit mounting.

Unit mounting sequence:

• Remove the mounting screws of the service side panel of the unit and take it off.

• Install the humidity sensor into the mount from the side of the extract air duct and connect the humidity sensor connector to the

respective connector coming from the control unit, refer to the External wiring diagram.

• Install the sensor cover back.

Washer

Nut

Threaded rod

Vibration absorbing rubber

min 20 mm

UNIT MOUNTING

The unit is designed for ceiling mounting with anchor threaded bolts, nuts and vibration-absorbing rubber.

Fasteners for unit mounting are not included in the delivery set and should be ordered separately.

While choosing fasteners consider the material of the mounting surface as well as the weigh of the unit, refer to the Technical Data

section. Fasteners for unit mounting should be selected by the service technician.

Before mounting make sure that the casing is free of any foreign objects like film or paper.

While installing the unit ensure convenient access for subsequent maintenance and repair.

Minimum required distance from the unit to the ceiling is at least 20 mm.

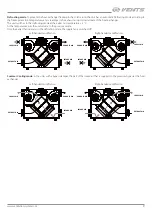

To attain the best performance of the unit and to minimise turbulence-induced air pressure losses, connect the straight air duct section

to the spigots on both sides of the unit while mounting.

Minimum straight air duct length:

• equal to 1 air duct diameter on intake side

• equal to 3 air duct diameters on outlet side

If the air ducts are too short or not connected, protect the unit parts from ingress of foreign objects.

To prevent uncontrollable access to the fans the spigots may be covered with a protecting grille or other protecting device with mesh

width not more than 12.5 mm.

Summary of Contents for VUE 100 P3B EC

Page 16: ...V146EN 04 ...