13

www.ventilation-system.com

VUT/VUE 550/900 PBW EC

Maintenance operations of the unit are required 3-4 times per year. They include general cleaning of the unit and the following operations:

1. Filter maintenance (3-4 times per year).

Dirty filters increase air resistance in the system and reduce supply air volume. The filters require cleaning not less than 3-4 times per year.

Clean the filter with a vacuum cleaner or replace it with a new one. For new filters contact the Seller.

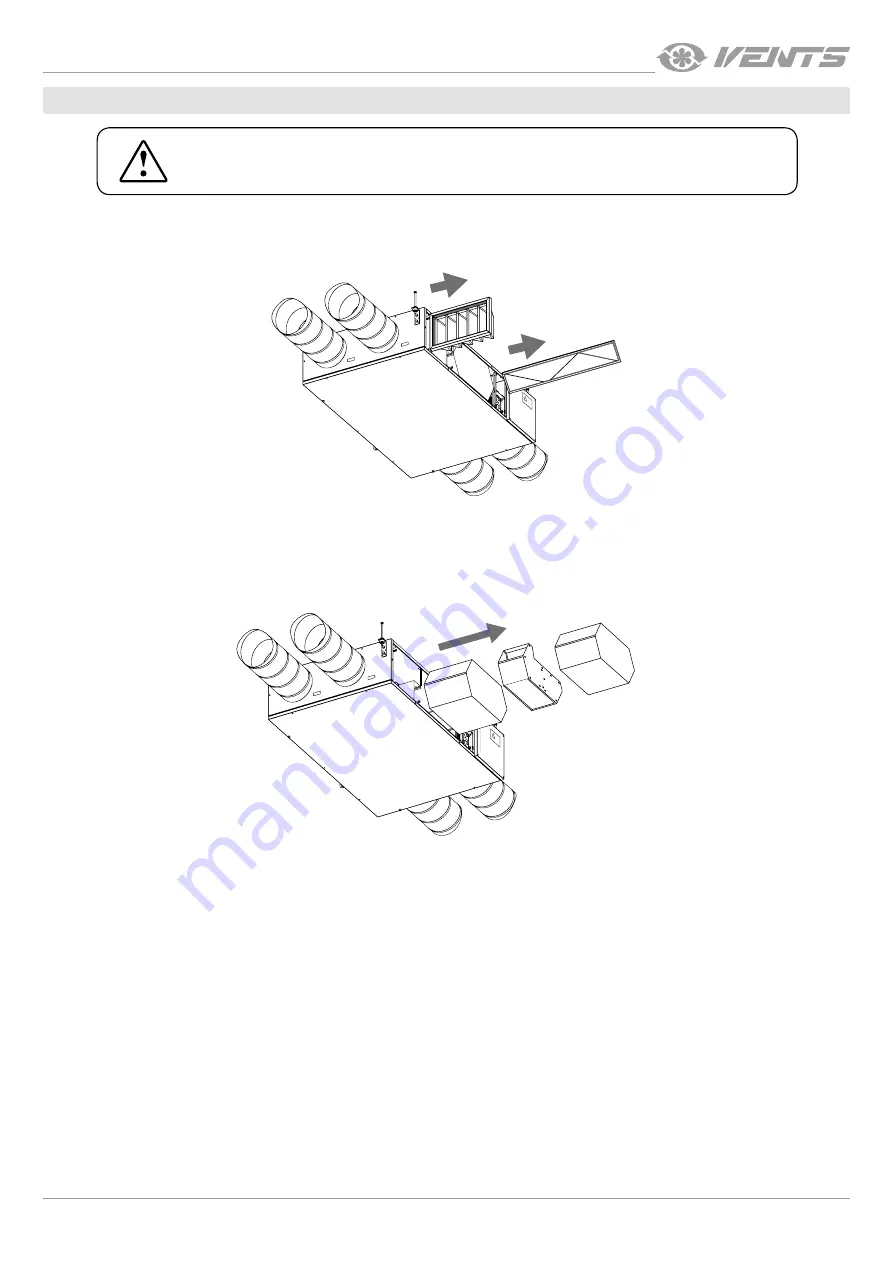

2. Heat exchanger maintenance (once per year).

Some dust may accumulate on the heat exchanger even in case of regular maintenance of the filters. To maintain the high heat recovery

efficiency, regular cleaning is required. To clean the heat exchanger, remove it from the unit and clean the heat exchanger by using

compressed air or a vacuum cleaner. In case of severe contamination, the heat exchanger can be washed with water.

After cleaning, reinstall the heat exchanger into the unit.

.

3. Fan maintenance (once per year).

Even in case of regular maintenance of the filters, some dust may accumulate inside the fans and reduce the fan performance and supply

air flow.

The fans must be cleaned by a service technician.

4. Condensate drainage system maintenance (4 times per year).

The condensate drainage (drain line) may get clogged by dirt and dust particles contained in the exhaust air.

Check the drain line operation by filling the drain pan under the unit with water, clean the U-trap and the drain line, if necessary.

5. Supply air flow control (twice per year).

The supply duct grille may get clogged with leaves and other objects reducing the unit performance and supply air delivery.

Check the supply grille twice per year and clean it as required.

6. Ductwork system maintenance (once in 5 years).

Even regular fulfilling of all the maintenance operations prescribed above may not completely prevent dirt accumulation in the air ducts,

which leads to air pollution and reduces the unit capacity.

Duct maintenance means regular cleaning or replacement.

TECHNICAL MAINTENANCE

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE

ANY MAINTENANCE OPERATIONS!