7

DESIGN AND OPERATING LOGIC

The unit operates as follows:

Warm stale extract air from the room flows through the air ducts to the unit, where it is filtered, then air flows through the heat exchanger

and is exhausted outside by the extract fan through the air ducts.

Clean cold air from outside is moved by the supply fan to the unit, where from it is directed to the supply filter. Then filtered air flows

through the heat exchanger and moves to the room through the air ducts.

Heat energy of warm extract air is transferred to clean intake fresh air from outside and warms it up. Heat recovery minimizes heat energy

losses, energy demand and operating costs for air heating accordingly.

The unit is equipped with a detachable service panel for repair works and preventive maintenance and a cover enabling access to the

control system components.

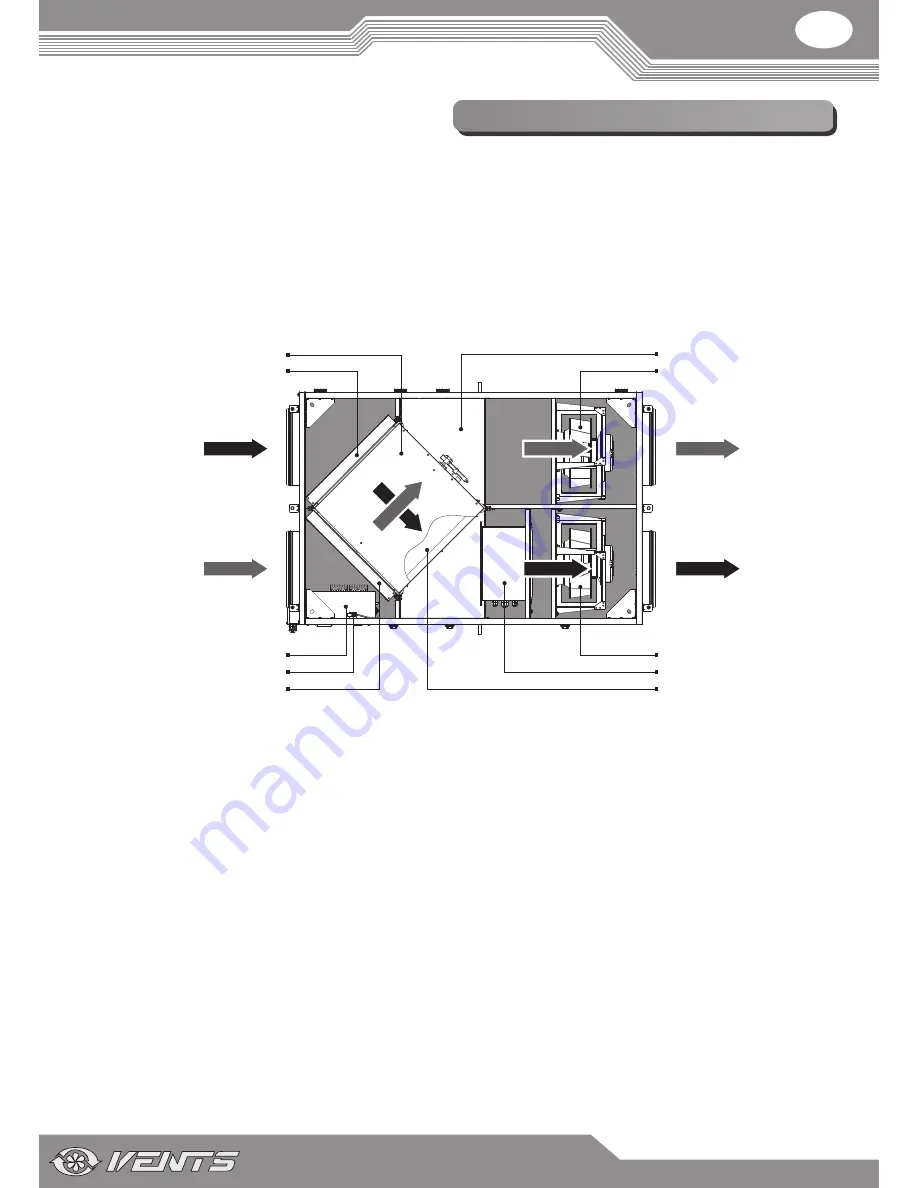

Intake air

Extract air

Exhaust air

Supply air

Supply fan

Electric heater

Cross-flow heat exchanger

Duct humidity sensor (option)

Extract filter

Control unit case

Extract fan

Drain pan

By-pass damper

Supply filter

DESIGN AND OPERATING LOGIC

(TOP VIEW)

The basic unit delivery set includes a remote control panel for connection to the control system inside the unit casing.

The unit comprises a supply and an extract centrifugal single-inlet fan with forward curved blades and maintenance-free EC motors with

external rotor and built-in overheat protection, a plate cross-flow heat exchanger, an electric heater, a supply and an extract filter.

The supply G4 filter cleans supply air flow and prevents contamination of the unit parts. The extract G4 filter prevents contamination of the

unit components.

Some condensate may be generated during heat recovery. The condensed fluid is collected in the drain pan and is removed from the unit

through the drain pipes.