13

CONNECTION TO POWER MAINS

DISCONNECT THE UNIT FROM POWER MAINS PRIOR TO ANY ELECTRIC INSTALLATION

OPERATIONS. CONNECTION OF THE UNIT TO POWER MAINS IS ALLOWED bY A QUALIFIED

ELECTRICIAN WITH A WORk PERMIT FOR THE ELECTRIC UNITS UP TO 1000 V AFTER CAREFUL

READING OF THE PRESENT USER’S MANUAL. THE RATED ELECTRICAL PARAMETERS OF THE UNIT

ARE SHOWN ON THE RATING PLATE. ANY INTERNAL CONNECTION MODIFICATIONS ARE NOT

ALLOWED AND RESULT IN WARRANTY LOSS.

L N PE 1

L

2

N

3

PE

4

1

5

2

6

3

7

c

8

nc

9

N

10

L

11

N

12

L

13

c

14

nc c

15

no

16

+12V

17

Gnd

Gnd Out

18

B

19

A

20

E+

21 22 23

L

M4

N PE

E+

TE1

+12V Gnd

Gnd Out

P1

B A

1

SM4

2 3

+

Y

1

DD1

2

1

PK1

2

1

SM1

2

1

SM2

Cooler

(no

-c

on

tac

t)

Po

w

er input

230 V

AC

2

N

L

N

L

t°

— ELECTRIC SHOCK HAZARD!

X1

L3

L2

L1

N PE 1

L

2

N

3

PE

4

1

5

2

6

3

7

c

8

nc

9

N

10

L

11

N

12

L

13

c

14

nc c

15

no

16

+12V

17

Gnd

Gnd Out

18

B

19

A

20

E+

21 22 23

L

M4

N PE

E+

TE1

+12V Gnd

Gnd Out

P1

B A

1

SM4

2 3

+

Y

1

DD1

2

1

PK1

2

1

SM1

2

1

SM2

Cooler

(no

-c

on

tac

t)

Po

w

er input

400 V

AC

2

N

L

N

L

t°

— ELECTRIC SHOCK HAZARD!

X1

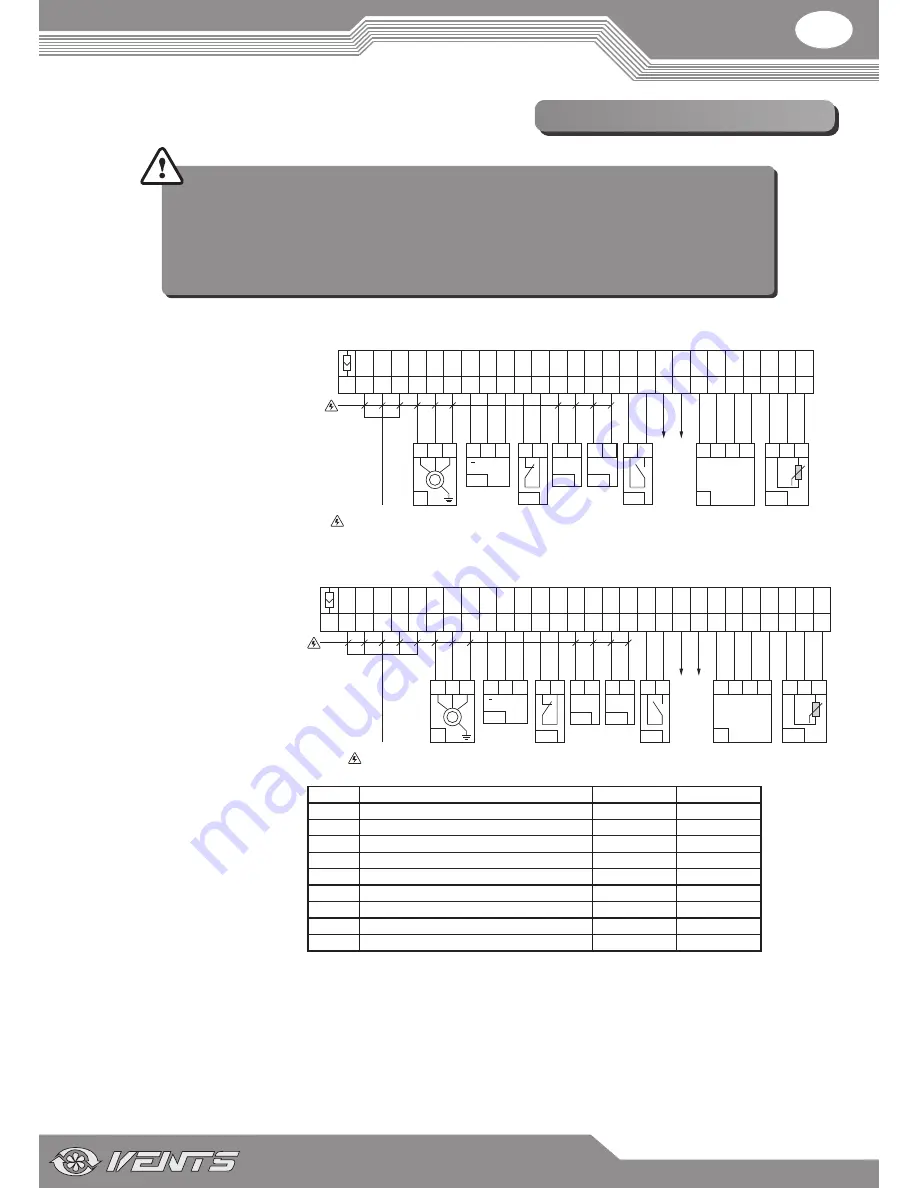

ExTERNAL WIRING DIAGRAM FOR THE UNIT VUT 2000 PW EC

ExTERNAL WIRING DIAGRAM FOR THE UNIT VUT 3000 PW EC

Design.

Name

Model

Wire

Cooler

DX cooler

NO

2 х 0,75 mm

2

DD1

Pump dry run protection relay

NC

2 х 0,75 mm

2

M4

Circulation pump of the heater

max. 0,3 kW

3 х 0,75 mm

2

SM1

Supply air damper actuator

LF230

2 х 0,75 mm

2

SM2

Extract air damper actuator

LF230

2 х 0,75 mm

2

SM4

3-way valve actuator

LR24 SR

3 х 0,75 mm

2

PK1

Contact from fire alarm panel

NO

2 х 0,75 mm

2

P1**

Control panel

4 х 0,75 mm

2

TE1

Outdoor air temperature sensor

3 х 0,75 mm

2

1. The unit delivery set includes P1 and TE1 only.

2. ** - Max. connecting cable length is 20 m.

The VUT 2000-3000 PW EC air-

handling unit is rated for connection

to single-phase AC 230 V / 50 Hz power

mains. The unit must be connected to

power mains using durable, insulated

and heat-resistant conductors (cables

and wires) with minimum cross section

not less than 2.5 mm

2

.

The VUT 2000-3000 PW EC air-

handling unit is rated for connection

to three-phase AC 400 V / 50 Hz power

mains. The unit must be connected to

power mains using durable, insulated

and heat-resistant conductors (cables

and wires) with minimum cross

section not less than 2.5 mm

2

.

The above cross section is for reference only. The applicable cable cross section must be selected depending on the wire type, its maximum

temperature and insulation, the maximum current, the wire length and its installation method.

Use copper wires only.

Connect the unit to power mains through the terminal block located in the terminal box on the side panel of the unit in compliance with the

wiring diagram and terminal marking. Connect all the control and supply cables in compliance with the terminal marking and polarity!

Connect the unit to power mains through the external automatic circuit breaker with a magnetic trip integrated into the fixed wiring system.

The trip current must be in compliance with current consumption.