12

VUT 300/550/900 PBE EC

www.ventilation-system.com

The recommended maintenance periodicity is 3-4 times per year.

The maintenance and servicing routines include regular cleaning and the following operations:

1. Filter maintenance (3-4 times per year).

Dirty filters increase air resistance in the system and reduce supply air volume. Clean the filters as these get dirty, but at least 3-4 times

a year. The filter can be cleaned with a vacuum cleaner or replaced with a new one. New filters can be purchased from the unit seller.

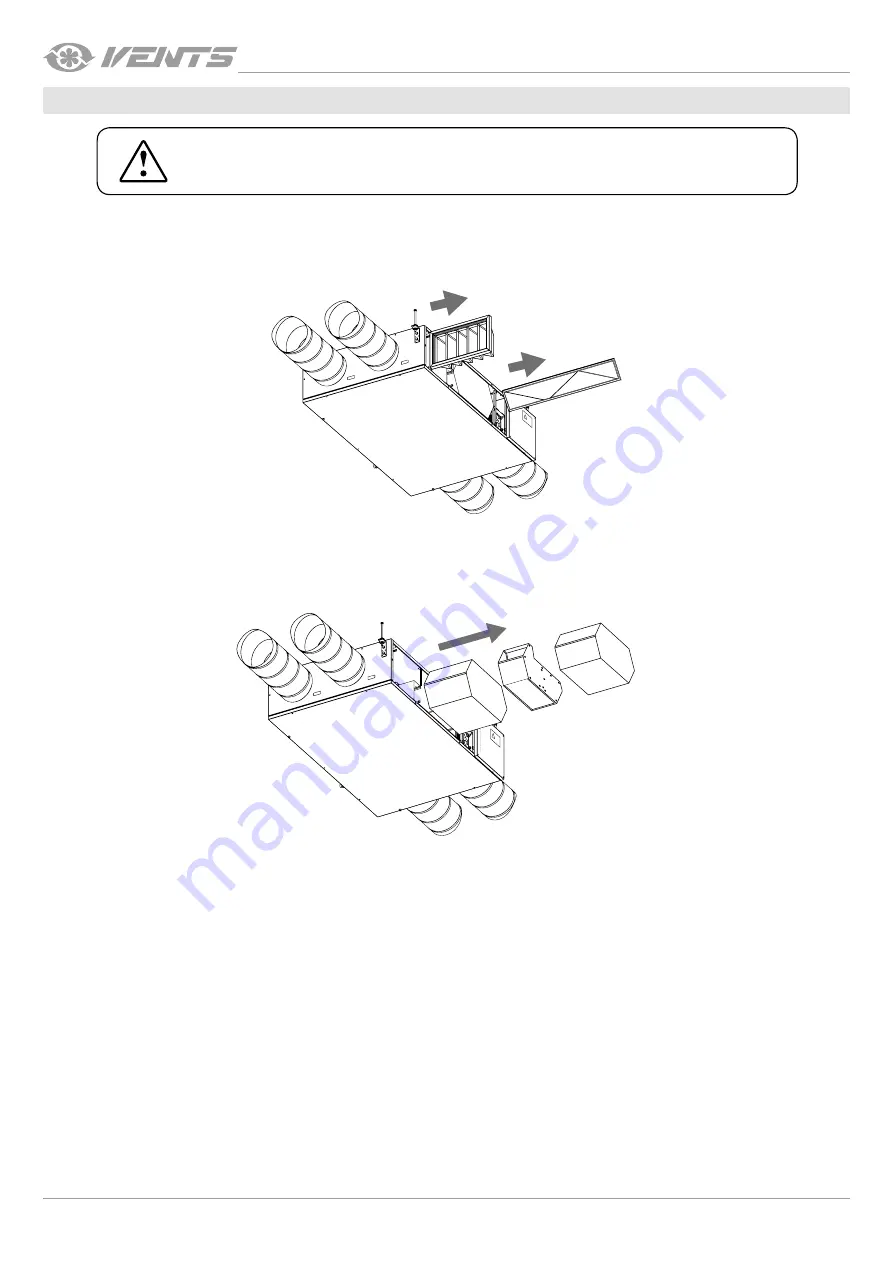

2. Heat exchanger maintenance (once a year).

Even regular filter technical maintenance may not completely prevent dirt accumulation on the heat exchanger.

To maintain high heat recovery efficiency, regular cleaning is required. To clean the heat exchanger, remove it from the unit and clean it

with compressed air or a vacuum cleaner. In case of heavy soiling, the heat exchanger can be washed with water.

Then install the heat exchanger back to the unit.

3. Fan inspection (once a year).

Even regular technical maintenance of the filters and the heat exchanger may not completely prevent dust accumulation in the fans

which reduces the fan capacity and impairs supply air volume into the premises.

The fans must be cleaned by a service technician.

4. Condensate drain maintenance (4 times a year).

The drain pipes may get clogged with the extracted particles.

Pour some water inside the drain pan and check the pipe for clogging. Clean the U-trap and drain pipe if required.

5. Air intake maintenance (twice a year).

Leaves and other pollutions can clog the supply air grille and reduce the unit performance and supply air volume.

Check the supply grille twice per year and clean it as required.

6. Duct system maintenance (every 5 years).

Even regular fulfilling of all the prescribed above maintenance operations may not completely prevent dust accumulation in the air ducts

which reduces the air quality and the unit performance. The air duct maintenance includes regular cleaning or replacement.

TECHNICAL MAINTENANCE

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE

ANY MAINTENANCE OPERATIONS!