www.ventilation-system.com

4

VUTR 200 V(E) EC

Due to the ability to save heating energy by means of energy recovery the unit is an important element of energy-effi

cient premises.

The unit is a component part and is not designed for stand-alone operation.

The unit is designed to ensure continuous mechanical air exchange in houses, offi

ces, hotels, cafés, conference halls and other utility and public

spaces as well as to recover the heat energy contained in the air extracted from the premises to warm up the fi ltered stream of supply air.

PURPOSE

THE UNIT MAY NOT BE OPERATED BY CHILDREN OR PERSONS WITH REDUCED PHYSICAL,

MENTAL OR SENSORY CAPACITIES, OR LACKING THE APPROPRIATE TRAINING.

THE UNIT MUST BE INSTALLED AND CONNECTED ONLY BY PROPERLY QUALIFIED PERSONNEL

AFTER THE APPROPRIATE BRIEFING.

THE CHOICE OF UNIT INSTALLATION LOCATION MUST PREVENT UNAUTHORIZED ACCESS BY

UNATTENDED CHILDREN.

The unit is designed for wall and fl oor mounting.

The unit is rated for continuous operation.

Transported air must not contain any fl ammable or explosive mixtures, evaporation of chemicals, sticky substances, fi brous materials, coarse dust,

soot and oil particles or environments favourable for the formation of hazardous substances (toxic substances, dust, pathogenic germs).

DELIVERY SET

Name

Number

Air handling unit

1 item

User's manual

1 item

Control panel

1 item

Decorative panel

1 item

Decorative panel mounting bracket

4 items

Fastening kit

1 item

Packing box

1 item

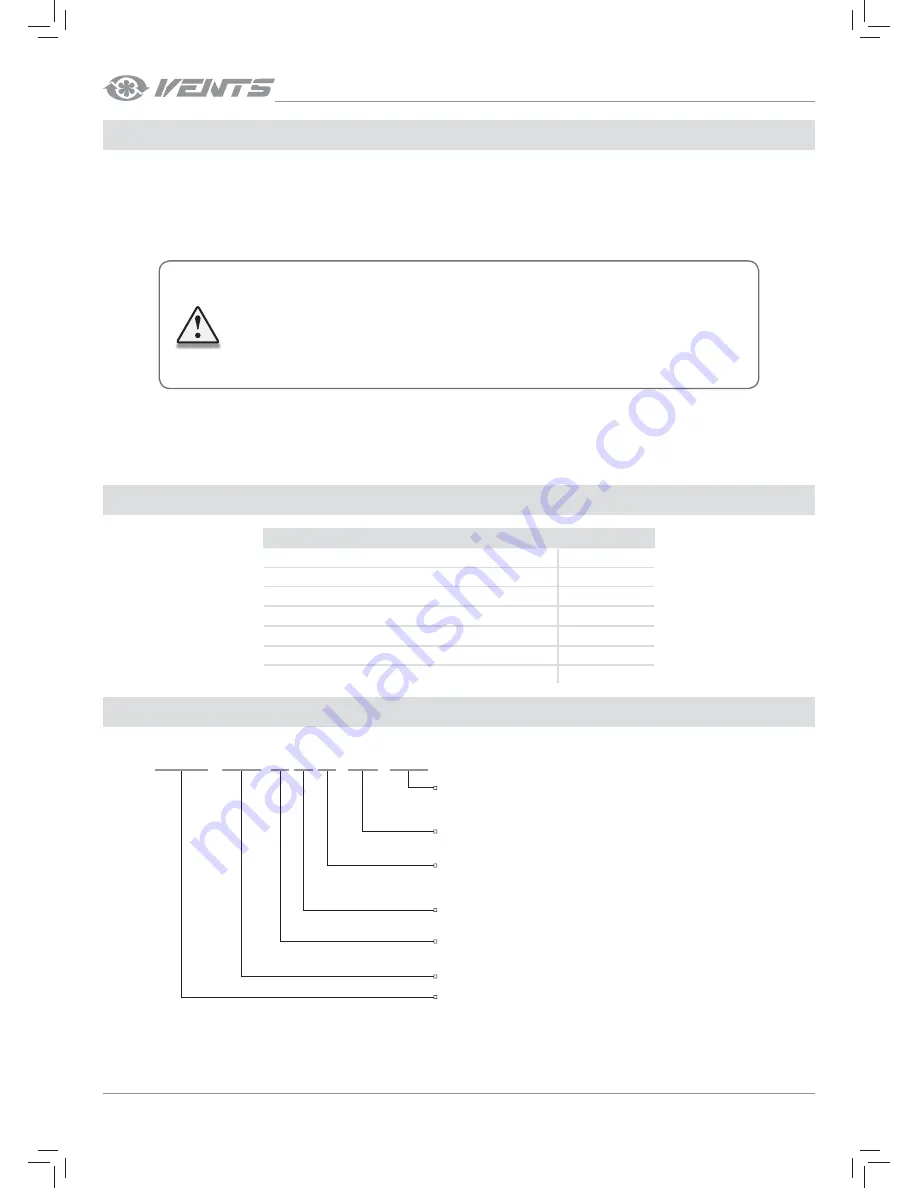

DESIGNATION KEY

VUTR 200 V 2 E EC A17

Control

A17 - th-Tune control panel with an LCD display

A18 - pGD1 control panel with an LCD display

Motor type

EC – electronically commutated

Electric heater

_ — without a heater

E - electrical heater

Panel thickness

2 — 20 mm

Spigot orientation

V - vertical spigot orientation

Rated air capacity [m

3

/h]

Series of units

VUTR - heat recovery air handling unit with a rotary heat exchanger

Summary of Contents for VUTR 200 V2 EC A17

Page 28: ...V140 1EN 01...