VENCO VENTURO INDUSTRIES LLC

CINCINNATI, OHIO

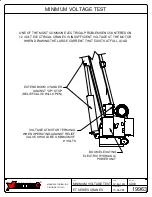

C200

MAN. OVERRIDE INSTR.

ET25/30/36KXP

09-16-19

DATE

SECTION

SUPERSEDES

TITLE

-

24415

MANUAL OVERRIDE INSTRUCTIONS

ET PROPRTIONAL SERIES CRANES

! ! R E A D A L L I N S T R U C T I O N S B E F O R E P E R F O R M I N G M A N U A L O V E R R I D E P R O C E D U R E S ! !

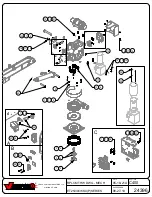

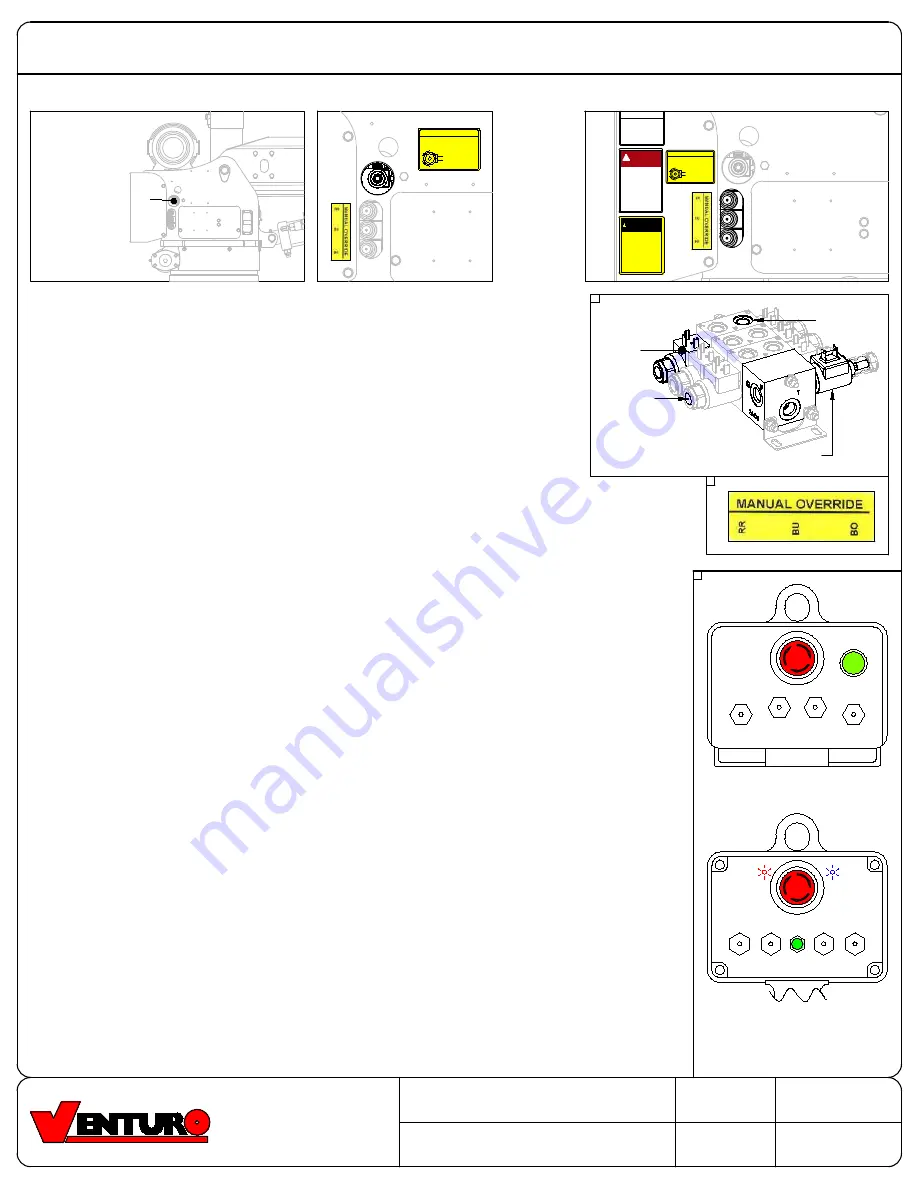

Each valve station incorporates [2] hydraulic ports and [2] coils. Manual

override shafts are located in the center of the coils (see figure 4).

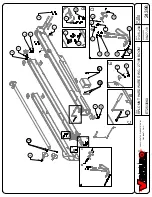

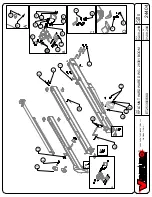

Manual override decals are placed on each crane near the valve assembly.

These decals provide a visual aid that helps the operator determine the function

designations (Reference figure 3 & 5).

3-STATION FUNCTIONS:

RR

=

Rot. Right

RL

=

Rot. Left

BU

=

Boom Up

BD

=

Boom Down

BI

=

Boom In

BO

=

Boom Out

21988

ALWAYS BE SURE TO CHECK HYDRAULIC OIL LEVEL BEFORE PROCEEDING. IT IS RECOMMENDED TO

REMOVE ANY ITEM(S) THAT MAY INTERFERE WITH OPERATING THE CRANE MANUALLY. IF POSSIBLE,

STRAPS AND/OR HARNESSES SHOULD BE REMOVED BEFORE OPERATING A CRANE IN MANUAL OVERRIDE !!

4

5

6

Procedure:

1.

Turn Master disconnect switch to "ON"

2.

Remove Protective cap (see figure 1)

3.

Rotate Valve Stem Clockwise to close (see figure 2)

4.

Power up the pendant / radio

4.1.

Twist EMERGENCY STOP button clockwise

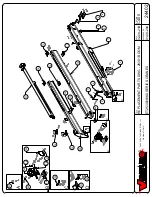

5.

On the crane, reference the function you wish to perform using the manual override decal (see

figure 3)

6.

Using a tool with a diameter of 1/8" or smaller, press the shaft inward and hold

7.

Reference the functions listed on your pendant or radio (see figure 6)

8.

Press the switch or button for the same function

9.

If you need to change function,

9.1.

Release switch or button

9.2.

Remove tool from shaft

9.3.

Go to step 5

For assistance, please feel free to contact Technical Support at 800-226-2238.

COIL

PORT

SHAFT

PROPORTIONAL COIL: MANUAL

OVERRIDE WITH GUARD

1

2

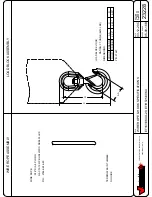

UP

OUT

UP

RIGHT

DOWN

IN

DOWN

LEFT

EXTENSION

WINCH

ELEVATION

ROTATION

P O

W

E R

E

M

E

R

G

E N C Y

S

T

O

P

HORN

UP

OUT

UP

RIGHT

DOWN

IN

DOWN

LEFT

BOOM

WINCH

BOOM

ROTATE

HORN

S

T

N

E

P

O

Y

C

G

R

E

M

E

P

O

T

S

Y

C

N

E

G

R

E

M

E

BATT

POWER

22158

23188

OVERRIDE

NORMAL

PROPORTIONAL

VALVE

ROTATE STEM

KEEP VALVE IN NORMAL POSITION.

OVERRIDE POSITION IS INTENDED

FOR EMERGENCY USE ONLY.

WARNING!

19315-2 Rev B

Protective Cap

23188

23188

THIS MACHINE IS NOT INSULATED

ELECTROCUTION HAZARD

MAINTAIN SAFE CLEARANCES FROM ELECTRICAL

LINES AND APPARATUS. YOU MUST ALLOW FOR

BOOM SWAY, ROCK OR SAG, AND ELECTRICAL

LINE AND LOAD LINE SWAYING.

THIS LIFTING DEVICE DOES NOT PROVIDE PRO-

TECTION FROM CONTACT WITH OR PROXIMITY

TO AN ELECTRICALLY CHARGED CONDUCTOR.

YOU MUST MAINTAIN A CLEARANCE OR AT LEAST 10

FEET BETWEEN ANY PART OF THE CRANE, LOAD

LINE OR LOAD, AND ANY ELECTRICAL LINE OR

APPARATUS CARRYING UP TO 50,000 VOLTS. ONE

FOOT ADDITIONAL CLEARANCE IS REQUIRED FOR

EVERY ADDITIONAL 30,000 VOLTS OR LESS.

DEATH OR SERIOUS INJURY

WILL RESULT FROM

CONTACT OR INADEQUATE CLEARANCE.

15392-E

DANGER

!

T HIS CR A NE IS N OT A PASSEN GER LIF T

IT IS NOT DESIGNED OR INTENDED TO BE USED TO LIFT,

SUPPORT OR OTHERWISE TRANSPORT PERSONNEL.

YOU MUST NOT

OPERATE THIS CRANE UNLESS:

1.

YOU HAVE BEEN TRAINED IN THE SAFE

OPERATION OF THIS CRANE; AND

2.

YOU KNOW AND FOLLOW THE SAFETY AND

OPERATING RECOMMENDATIONS CONTAINED IN

THE MANUFACTURER'S MANUALS, YOUR

EMPLOYER'S WORK RULES, AND APPLICABLE

GOVERNMENT REGULATIONS.

AN UNTRAINED OPERATOR SUBJECTS HIMSELF

AND OTHERS TO

DEATH OR SERIOUS INJURY .

15391-D

15390-D

!

CAUTION

1. INSPECT VEHICLE AND CRANE INCLUDING

OPERATION, PRIOR TO USE DAILY.

2. DO NOT USE THIS EQUIPMENT EXCEPT ON

SOLID, LEVEL SURFACE WITH CRANE

MOUNTED ON FACTORY-RECOMMENDED

TRUCK.

3. BEFORE OPERATING THE CRANE, REFER TO

MAXIMUM LOAD (CAPACITY) CHART ON CRANE

FOR OPERATING (LOAD) LIMITATIONS.

4. DO NOT OPERATE, WALK, OR STAND BENEATH

BOOM OR A SUSPENDED LOAD.

5. UNPLUG PENDANT AND SHUT OFF MASTER

DISCONNECT SWITCH WHEN CRANE NOT IN

USE.

6. FOR TRAVEL, BOOM MUST BE IN STOWED

POSITION.

OVERRIDE

NORMAL

PROPORTIONAL

VALVE

ROTATE STEM

KEEP VALVE IN NORMAL POSITION.

OVERRIDE POSITION IS INTENDED

FOR EMERGENCY USE ONLY.

WARNING!

19315-2 Rev B

3

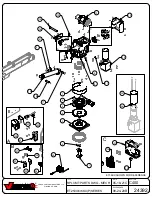

Summary of Contents for ET30KX

Page 2: ......

Page 4: ......

Page 5: ...TFDUJPO 100 DESCRIPTION SPECIFICATIONS 7607100B ...

Page 10: ......

Page 12: ...TFDUJPO 150 SAFETY 8604150 ...

Page 21: ...TFDUJPO 200 JOTUBMMBUJPO 7607200B ...

Page 27: ...TFDUJPO 300 NBJOUFOBODF TFSWJDF 7607300B ...

Page 33: ...TFDUJPO 400 QBSUT 7607400B ...

Page 62: ......

Page 64: ......