4.7.2.5

User Settings

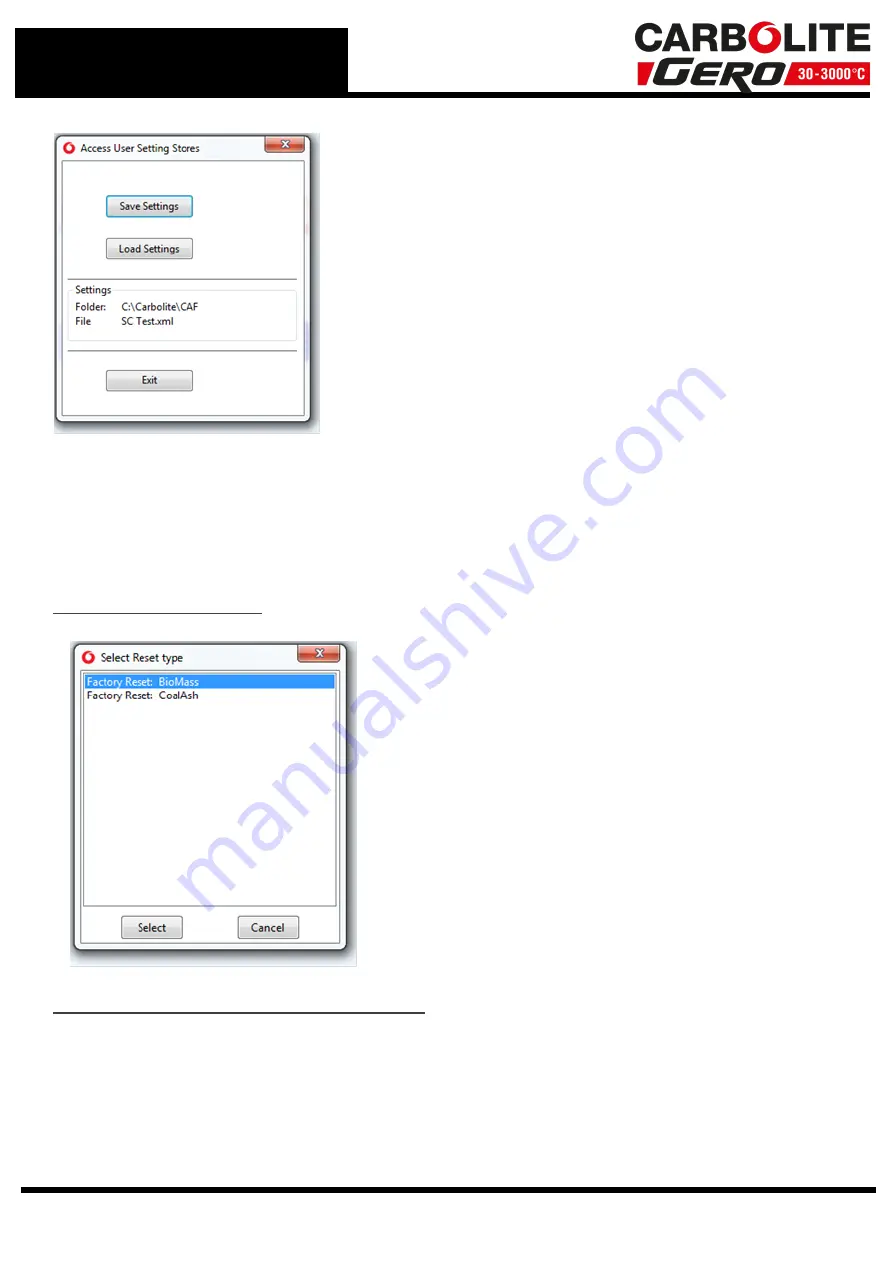

Clicking the 'User Settings' button will open this window.

The Temperature Settings, Test Identifications Settings

and the Analysis Grid Settings can be stored in one unique

file.

Save Settings

- Once the Temperature Settings, Test Identification Settings and the

Analysis Grid Settings have been adjusted the value can be saved to a custom file name

in a folder location of the users choice.

Note

: There is no limit to the number of

configuration files that can be saved.

Load Settings

- Select the file name of any previously saved user settings.

Settings

- The settings panel shows the current user settings loaded and its file location.

4.7.2.6

Factory Reset

Clicking the 'Factory Reset' button opens this

window.

The temperature Settings Test Identification

Settings and the Analysis Grid settings can all be

reset back to the factory default settings.

Note

: this does not delete any of the saved user

settings files.

Highlight the appropriate test type and press the

select key to reset factory defaults.

4.7.2.7

Backlight Intensity (If Available)

The back-light intensity is located in the lower part of the command window and can be

adjusted with either the slider bar or by directly inputting a percentage light intensity

value in the numerical box above the slider. This cannot be adjusted once the test is

started.

34

Summary of Contents for CARBOLITE GERO CAF G5

Page 63: ...Fig 3 Front Tube Seal Assembly Fig 4 Door Arm Assembly 63 ...

Page 64: ...Fig 5a Camera Mounting Bracket Fig 5b Lens and Camera Assembly 64 ...

Page 65: ...Fig 5c Sliding the Camera Mounting Bracket Assembly onto the Door Arm 65 ...

Page 66: ...Fig 5d Securing the Camera Mounting Bracket Assembly to the Door Arm 66 ...

Page 67: ...Fig 5e Mounting the Lens and Camera Assembly 67 ...

Page 68: ...Fig 5f Lens and Camera Assembly in Position 68 ...

Page 69: ...Fig 6a Rear View of the Standard CAF G5 Furnace Showing Brick Box Assembly 69 ...

Page 71: ...Fig 7 Front Tube Seal Position 71 ...

Page 72: ...Fig 8 Tube End Seal Assembly Tightening Sequence Fig 9 Work Tube Front Support 72 ...

Page 73: ...Fig 10 Fitting the Door Arm Assembly Fig 10a Adjusting the Door Arm Assembly 73 ...

Page 74: ...Fig 11a Furnace Case and Controls 74 ...

Page 75: ...Fig 11b Gas Inlet Pipe Fig 12 Positioning the Furnace 75 ...

Page 77: ...Fig 13c Loading Samples into the Work Tube 77 ...

Page 78: ...Fig 16 File Folder 78 ...

Page 79: ...Fig 17 Door Arm Assembly Exploded View 79 ...

Page 82: ...SST DT HT FT Fig 18 Report Sheet Page 2 Side View Plan View Fig 19 Formed Wire Sample 82 ...

Page 83: ...Fig 20 Sample Carrier Sample Tiles and Sample Positions 83 ...

Page 84: ...Fig 21a Coal and Coke Test Piece Mould Fig 21b Biomass Test Piece Mould and Hand Press 84 ...

Page 85: ...Fig 22 Sample Loading Tool Fig 23 Camera Ethernet Connection 85 ...

Page 86: ...Fig 24 LED Driver Connection 86 ...

Page 87: ...Notes Service Record Engineer Name Date Record of Work ...