6. Set the front panel in the remaining grooves closest to the

keyhole slots.

7. Attach the front panel to the side panels and stretcher with

#8 × 1 1/4

"

pan-head screws.

8. Carefully flip the entire assembly over, right side up. Ensure

the frame members are still located in the grooves in the

underside of the base panel.

9. Secure the base panel to the frame and stretcher using the

#8 × 1 3/4

"

flat-head screws.

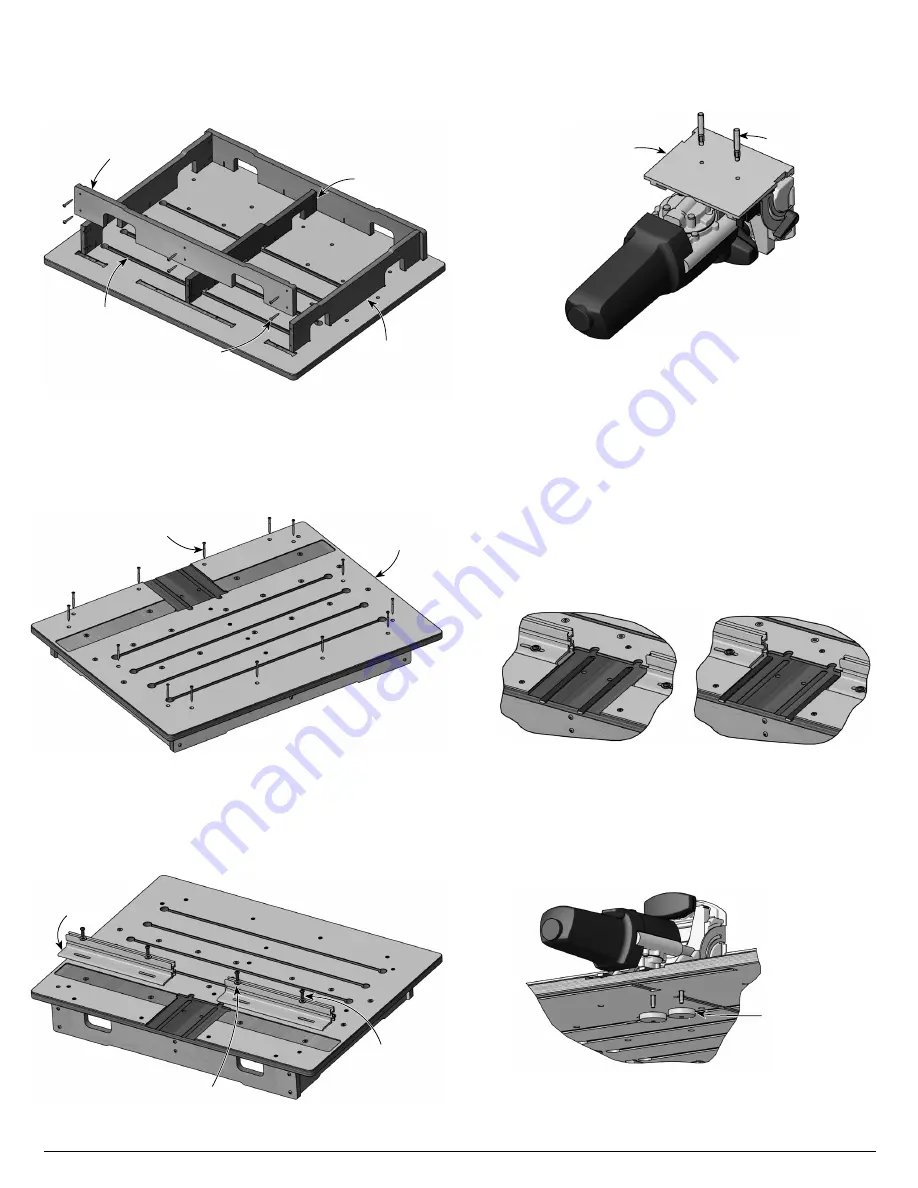

10. Place the two aluminum fixed fences in the milled cavity in

the top and push them against the milled sides of the cavity

to ensure the two fences are aligned with each other. Secure

the fences in place with the 1/4-20 × 3/4

"

button-head

screws and 1/4

"

washers.

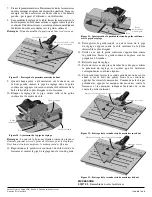

Mounting the Domino

1. Thread the two mounting studs into the M5 holes in the

bottom of the Domino base plate. The mounting studs need

only be finger tight.

2. Use the pair of 6 mm thick shims to adjust the 5 mm vertical

offset of the mortise to 10 mm or 11 mm from the base

surface of the joinery table.

a. To establish a 10 mm vertical offset, place the 6 mm thick

shims into the slots in the milled cavity for the Domino

base plate.

b. For an 11 mm vertical offset, butt a 6 mm thick shim

against either side of the cavity.

c. With no shims, the center line of the Domino bit will be

5 mm from the base surface of the joinery table.

d. If a greater range of offsets is desired, an accessory shim

pack with 2 mm, 4 mm and 8 mm pairs of shims is

available separately.

3. Insert the mounting studs in the Domino base plate through

the holes in the base surface of the joinery table. Secure with

two brass knobs. Do not fully tighten the knobs.

Note:

You may need to move the fixed fence to clear some of the

adjustment knobs on the Domino.

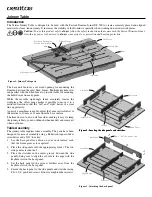

Base Panel

#8 × 1 3/4

"

Flat-Head Screw

Figure 5: Securing the base panel to the frame.

Figure 8: Adjusting the vertical offset with shims.

6 mm shims placed in the slots

6 mm shims placed on the sides

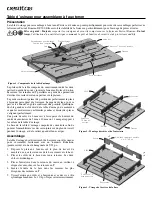

Figure 6: Attaching the fixed fences.

1/4-20 × 3/4

"

Button-Head Screw

Fixed Fence

1/4

"

Washer

Figure 7: Installing the mounting studs in the Domino base plate.

Mounting Stud

Domino Base Plate

Figure 9: Installing the Domino to the base surface.

(Panel frame members removed for clarity.)

Brass Knob

2

Stretcher

Front Panel

Side Panel

Keyhole Slot

#8 × 1 1/4

"

Pan-Head Screw

Figure 4: Attaching the front panel.