Installing the Right-Angle Fence and

Hold-Downs

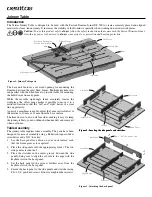

1. Align the two cut-outs in the edge of the right-angle fence

with the spring stops in the face of the Domino.

2. Ensure the right-angle fence is in contact with the fixed fences.

3. Secure the right-angle fence with the two wing knobs

threaded into the insert nuts.

4. Align the Domino face with the right-angle fence and tighten

the brass knobs. This aligns the Domino to the fixed fences.

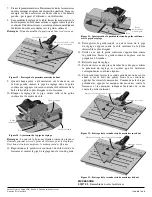

5. Install the hold-downs through the holes in the ends of the

keyhole slots. The end of the T-bolt should engage the

undercut in the keyhole slot.

Note:

In practice, the hold-downs will need to be moved to

different keyhole slots, as needed, to adequately hold a workpiece

in place.

The joinery table is now ready to use.

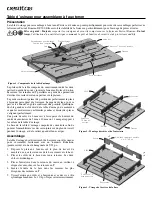

Cutting Mortises in Mitered Joints

1. Cut and miter all the parts of your project/frame to length.

2. Lay out the parts to form the frame and mark all the joint

locations to indicate which side is up. Notice that each part

has a left and right end, and the geometry of these ends

creates mirror images.

3. On at least one of the joints, also mark the desired center of

the loose tenon. In our example, we used a capital letter R

on the left end of the part. This reference mark will be used

for the initial set-up of the joinery table.

Note:

As with all joinery cut by machine, it is good practice to

have a number of extra parts to use for testing the set-up. This is

particularly important when configuring the joinery table for the

second half of the joint.

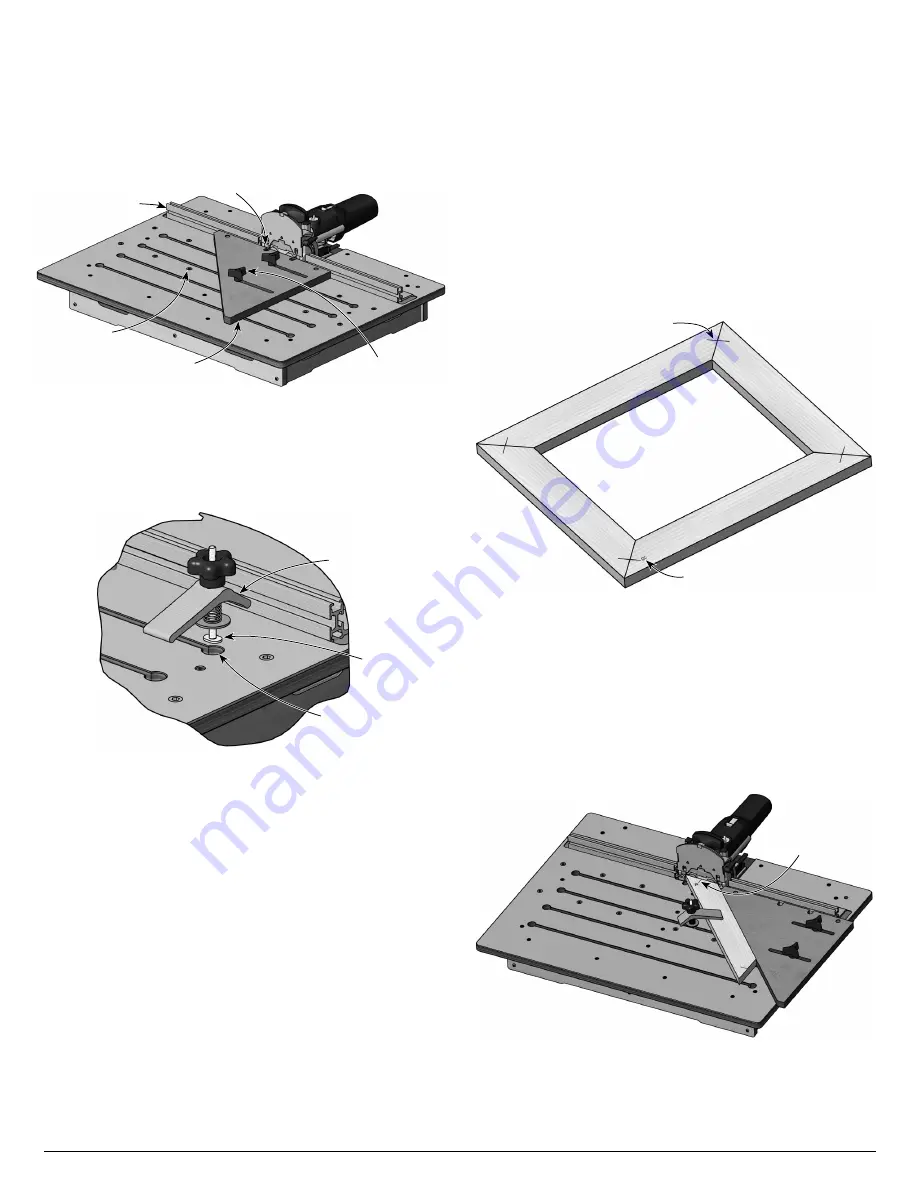

4. Using the part specifically marked for set-up, align the

reference mark with the centerline mark on the face of

the Domino.

5. Clamp the part in place using at least one hold-down. Larger

parts may require two hold-downs.

6. Slide the right-angle fence against the part, ensuring it is

also tight against the fixed fence. Lock the right-angle fence

in place using the wing knobs.

7. Cut the left mortise.

8. Replace the part with the next frame piece and proceed to

cut the left mortise in the end of the three remaining parts.

Right-Angle Fence

Spring Stop

Fixed Fence

Wing Knob

Insert Nut

Figure 10: Aligning the Domino to the fixed fences.

Hold-Down

T-Bolt

Keyhole Slot

Figure 11: Installing the hold-downs.

Figure 12: Example of a typical mitered frame. Note joint location

marks across each miter.

Joint Location Marks

Reference Mark

Figure 13: Cutting the first mortise.

Reference Mark

3