7. Cut the first mortise. Proceed to cut all the mortises that

are in a similar location. In our example, we cut the two

mortises that are in the side grain on the left-hand end of

the part.

8. Without changing the joinery table set-up, cut the two end-

grain mortises on the left-hand end of the part. Ensure that

the mark indicating the outside of the frame is in contact

with the right-angle fence.

Note:

You will need to move the location of the hold-down, as we

did in our example.

9. Once each part has one mortise cut in either the side

grain or the end grain, place the offset gauge in the hole

in the right-angle fence and adjust the gauge so the cursor

registers against one of the spring stops on the front face of

the Domino.

10. Lock this setting, and then remove the offset gauge from the

right-angle fence and set it aside.

Note:

While there are a number of features on the face of the

Domino that can be used for reference alignment, make it a habit

to consistently use the same reference point.

11. Reposition the right-angle fence on the right side of the

Domino and place the offset gauge in the hole in the right-

angle fence.

12. Slide the fence/gauge assembly until the cursor is aligned

with the opposite spring stop.

13. Ensure the right-angle fence is tight against the fixed fence.

Lock it in place using the wing knobs.

14. Remove the offset gauge.

15. Make a test cut with a scrap piece of the frame material

to ensure the set-up is correct and the desired mating joint

alignment is achieved.

16. If all is correct, proceed to cut the second set of side-grain and

end-grain mortises. (If not, adjust as required.) As before, place

the parts such that the mortise mark is against the Domino and

the outer mark is against the right-angle fence.

Accessory

05J17.02

Optional Shim Pack, set of 6

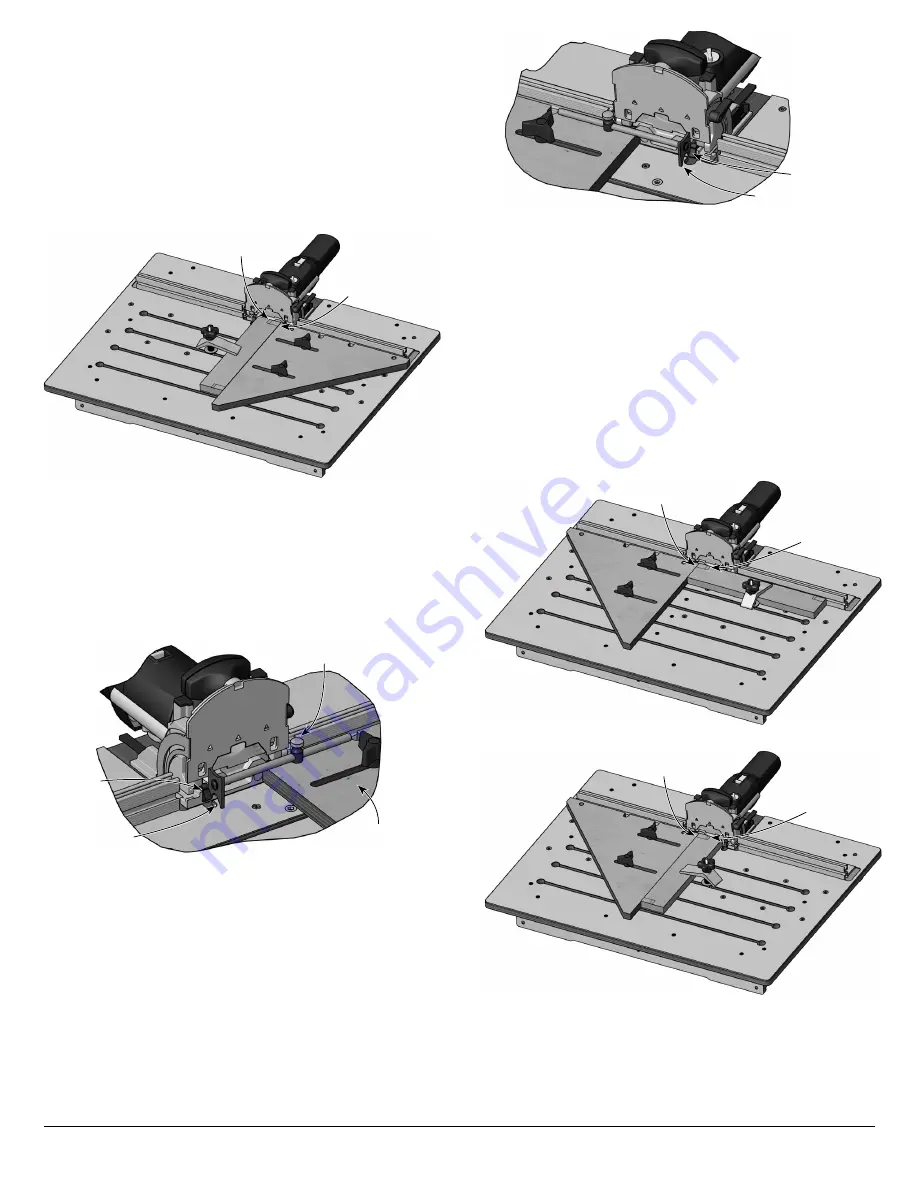

Cursor

Offset Gauge

Spring Stop

Right-Angle Fence

Figure 20: Setting the offset gauge.

Figure 21: Repositioning the right-angle fence and setting the

mortise distance with the offset gauge.

Outermost

Spring Stop

Cursor

Figure 23: Cutting the second set of end-grain mortises.

End-Grain Mortise

Outside mark against

the right-angle fence

Figure 22: Cutting the second set of side-grain mortises.

Side-Grain Mortise

Outside mark against

the right-angle fence

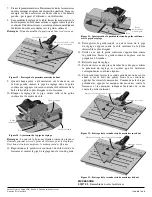

Figure 19: Cutting the first end-grain mortise.

End-Grain Mortise

Outside mark against

the right-angle fence

Veritas Tools Inc. Ottawa ON K2H 1C2 Canada veritastools.com

© Veritas Tools Inc. 2022

1380 INS-780_B