4

Tip:

If you do not have a vise, you can improvise with a piece of 2×4 with various sizes

of V-shaped notches cut in it and two C-clamps. Place the piece of wood in a notch

slightly smaller than its diameter, and clamp the 2×4 to a bench or a large stable surface.

Place the tenon cutter on the end of the piece of wood and adjust the drill by eye so that it is in

line with the piece of wood. The tenon cutter will cut tenons in line with the axis of the drill. If

you wish to have a tenon come out of the end of the piece of wood at an angle, clamp the piece

in a vise at the desired angle (using an inclinometer if necessary). Cut the tenon while holding

the tenon cutter straight and level.

Note:

Whether you are cutting in-line or angled tenons, the secret to cutting a uniform tenon is

to keep the drill very steady while cutting.

While leaning into the wood, switch on the drill at a moderate speed (800 to 1000 rpm). Turning

too fast may cause you to wander from a straight cut. If the blade is properly set, the shaving of

wood will curl out of the tenon cutter as it rotates. If the tenon cutter stops cutting or does not

cut at all, you will need to adjust the blade.

Note:

The tenon cutter’s shank has a hole drilled down the center. This is to allow you to insert

a

3

/

16

" dia. pin into the back end to drive out a broken tenon.

Adjusting the Blade

Caution:

Be aware that the blade is sharp; careless handling can result in serious injury.

A brass plug gauge has been provided to help you obtain the desired tenon diameter.

Adjusting the Tenon Diameter

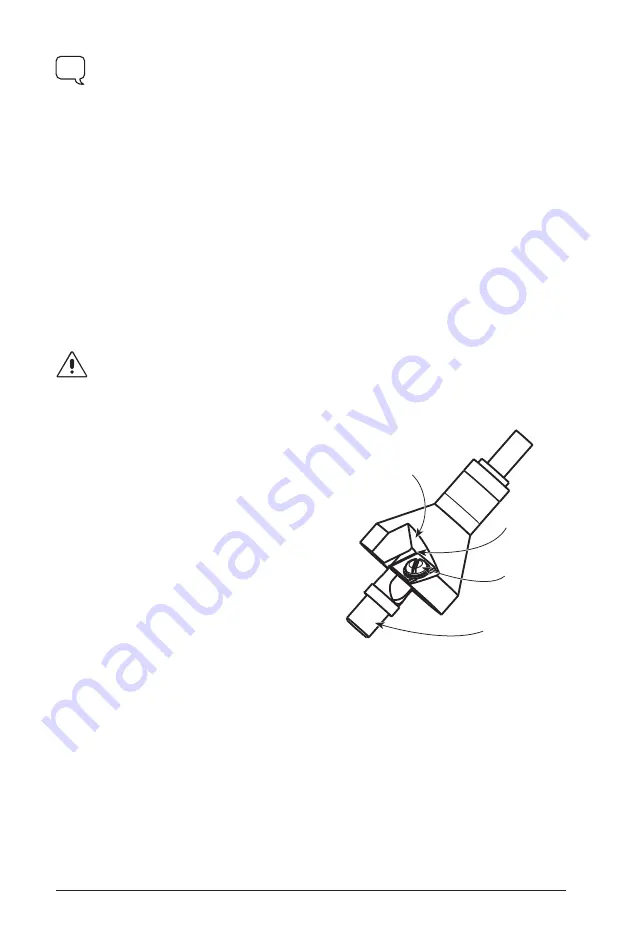

Loosen the blade clamping screw slightly to just

allow the blade to slide with minimal vertical

play. Insert the plug gauge into the tenon cutter,

rotating it so that either of the two round surfaces

faces the blade. Lightly push the blade in until

the front corner (the part that determines the fi nal

tenon diameter) touches the plug gauge, while the

right-hand edge remains in contact with the body

shoulder. Firmly tighten the blade clamping screw.

Rotate the plug in either direction until the round

surfaces are no longer touching the blade. While

the fl at on the gauge provides clearance under

the blade, withdraw the gauge. Make a test

cut and measure the tenon. If the tenon is not

cutting the desired size, repeat this procedure, or

see

Troubleshooting

.

...

Body

Shoulder

Blade

Clamping

Screw

Plug Gauge

Front Corner

of Blade

Figure 1: Adjusting the blade.