Note:

The plug gauge will develop small

scratches as it is repeatedly rotated against

the blade prior to removal. It has been

made of soft brass so that it does not nick

the corner of the blade. It has also been

made long enough so that you may place it

in the tenon cutter at varying depths to find

an unblemished area.

While adjusting the blade, never allow the

blade to override the plug. Doing so will

cause deep scratches in the gauge as it is

rotated prior to removal, and likely result

in undersized tenons.

Tenon Length

A tenon cut to full depth will be 1

"

long with

the

1

/

4

",

5

/

16

"

and

3

/

8

"

dia. tenon cutters, and

1

3

/

8

"

long with the

7

/

16

",

1

/

2

"

and

9

/

16

"

dia.

tenon cutters. To cut shorter tenons, just stop

cutting before bottoming out.

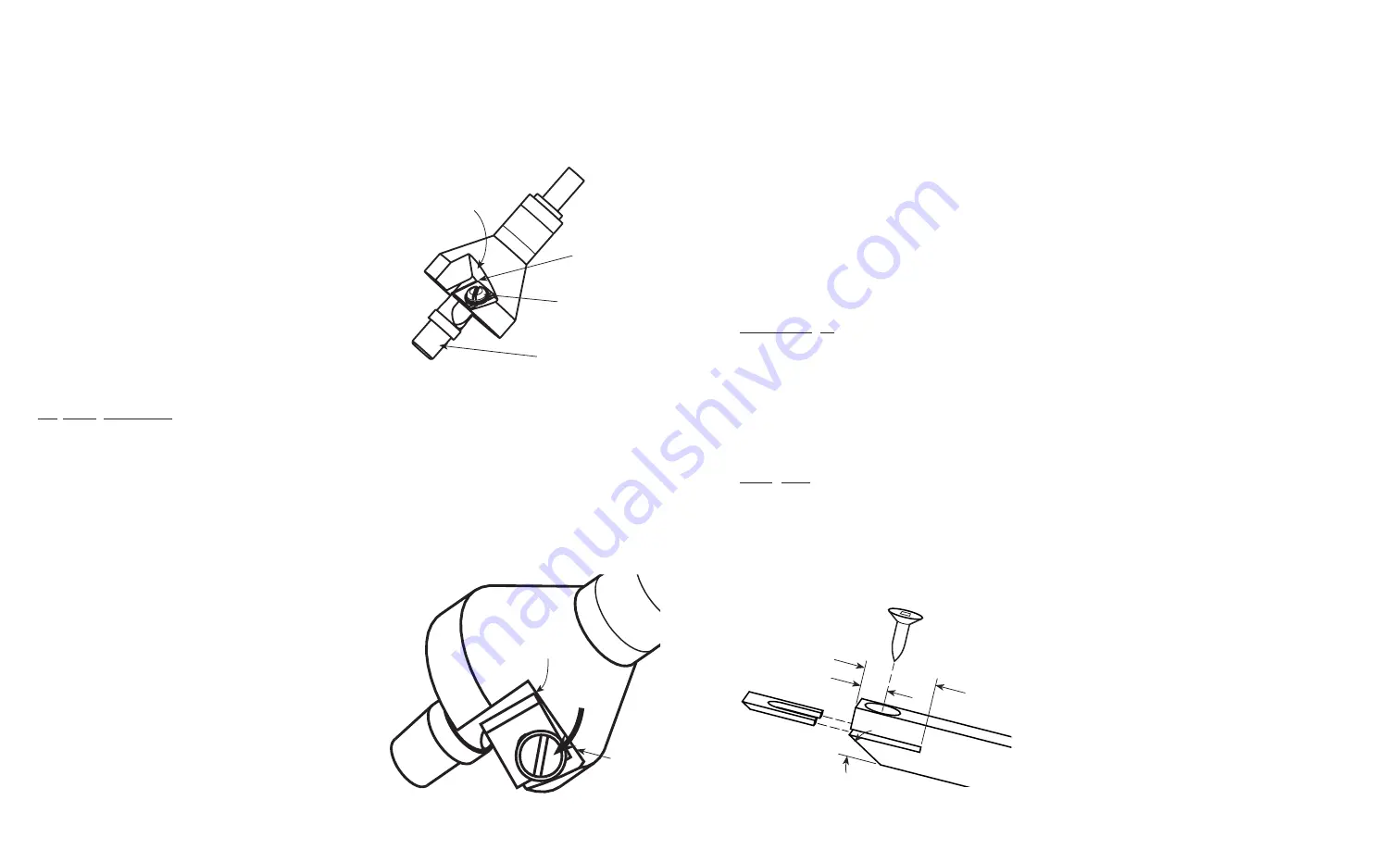

Sharpening

You can hold the small blade for sharpening

by making a blade holder from

1

/

2

"

square

stock, 4

"

to 6

"

long. Using a bandsaw or

other thin blade, cut a center groove at least

3

/

4

"

deep in one end. Drill a

3

/

16

"

dia. hole

perpendicular to the groove,

3

/

16

"

from

the end, and just deep enough to reach the

groove. Countersink to accommodate a

#10 ×

1

/

2

"

flat-head wood screw. Chamfer

the front portion of the non-drilled section

below the slit at approximately 30°.

Insert the blade in the slot (bevel facing

the chamfered section). Secure it in place

with the #10 ×

1

/

2

"

flat-head wood screw.

Coat the entire length of the bevel with an

indelible marker. Clamp the blade holder

in a honing guide at a 30° angle, and

progressively hone the blade to 4000x.

Observe where the marker coating has

worn off. Continue sharpening until the

full width of the blade is clear of marker

coating (and at least

1

/

32

"

wide). Check to

ensure that the bevel remains square to the

side edge of the blade.

Alternatively, you can sharpen the blade

held at a 30° angle against a belt sander

(fitted with a 180x belt for rough sharpening,

progressing to 15µ or finer for finishing).

Do

not

hold the blade in contact with the

belt for extended periods of time (more

than few seconds) or you may overheat the

blade. Use indelible marker as described

above to ensure that the entire bevel has

been sharpened and remains square to the

side edge of the blade.

Remove the blade from the holder. To

remove the wire burr from the edge of

the blade, draw the face across a fine grit

(1000x or higher) sharpening stone or a

piece of silicon carbide abrasive paper on

a flat surface.

6

3

/

4

"

1

/

2

"

×

1

/

2

"

stock,

4

"

to 6

"

long.

3

/

16

"

30°

Figure 3: Shop-made blade holder.

Note:

Whether you are cutting in-line

or angled tenons, the secret to cutting

a uniform tenon is to keep the drill very

steady while cutting.

While leaning into the wood, switch on the

drill at a moderate speed (800 to 1000 rpm).

Turning too fast may cause you to wander

from a straight cut. If the blade is properly

set, the shaving of wood will curl out of the

tenon cutter as it rotates. If the tenon cutter

stops cutting or does not cut at all, you will

need to adjust the blade.

Note:

The tenon cutter’s shank has a hole

drilled down the center. This is to allow you

to insert a

3

/

16

" dia. pin into the back end to

drive out a broken tenon.

Adjusting the Blade

A brass plug gauge has been provided to

help you obtain the desired tenon diameter.

To Adjust the Tenon Diameter:

Loosen the blade clamping screw slightly

to just allow the blade to slide with minimal

vertical play. Insert the plug gauge into the

tenon cutter, rotating it so that either of the

two round surfaces faces the blade. Lightly

push the blade in until the front corner

(the part that determines the final tenon

diameter) touches the plug gauge, while

the right-hand edge remains in contact with

the body shoulder. Firmly tighten the blade

clamping screw.

Rotate the plug in either direction until

the round surfaces are no longer touching

the blade. While the flat on the gauge

provides clearance under the blade,

withdraw the gauge. Make a test cut

and measure the tenon. If the tenon is

not cutting the desired size, repeat this

procedure, or see

Troubleshooting

.

Figure 1: Adjusting the blade.

To Adjust the Shaving Thickness:

The blade can be adjusted to cut more

aggressively to produce larger shavings.

Repeat the above procedure, but swivel

the blade away from the body shoulder,

rotating it about the right-hand front

corner, which is to remain in contact with

the plug gauge.

Figure 2: Adjusting shaving thickness.

5

Body

Shoulder

Swivel about front

corner of blade

Body

Shoulder

Blade

Clamping

Screw

Plug Gauge

Front Corner

of Blade