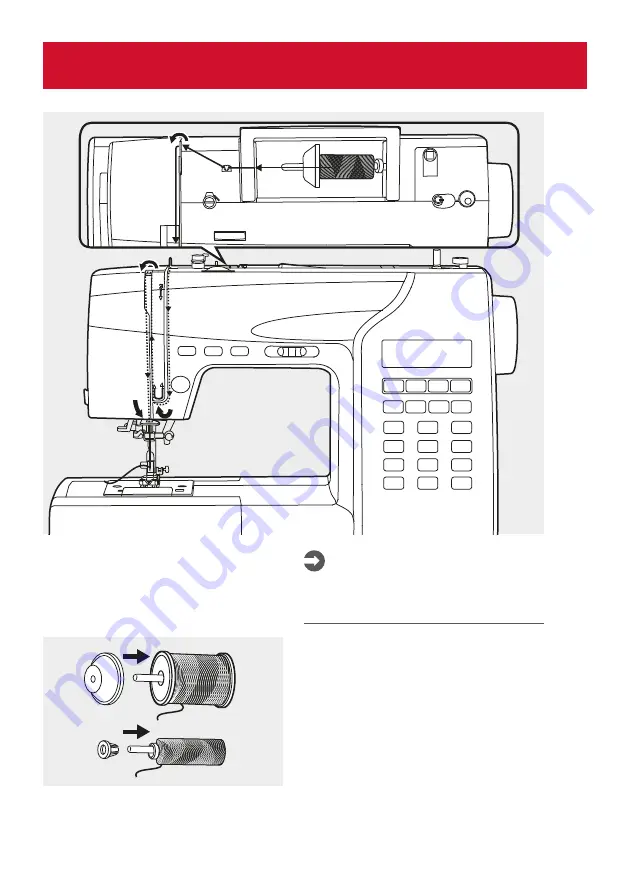

Threading the upper thread

Please Note:

It is important to carry out the threading

correctly otherwise sewing problems

may result.

5

7

8

6

1

2

4

3

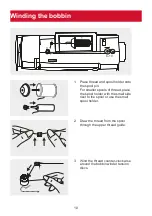

1. Place thread and spool holder onto

the spool pin.

For smaller spools of thread, place

the spool holder with the small side

next to the spool or use the small

spool holder.

14