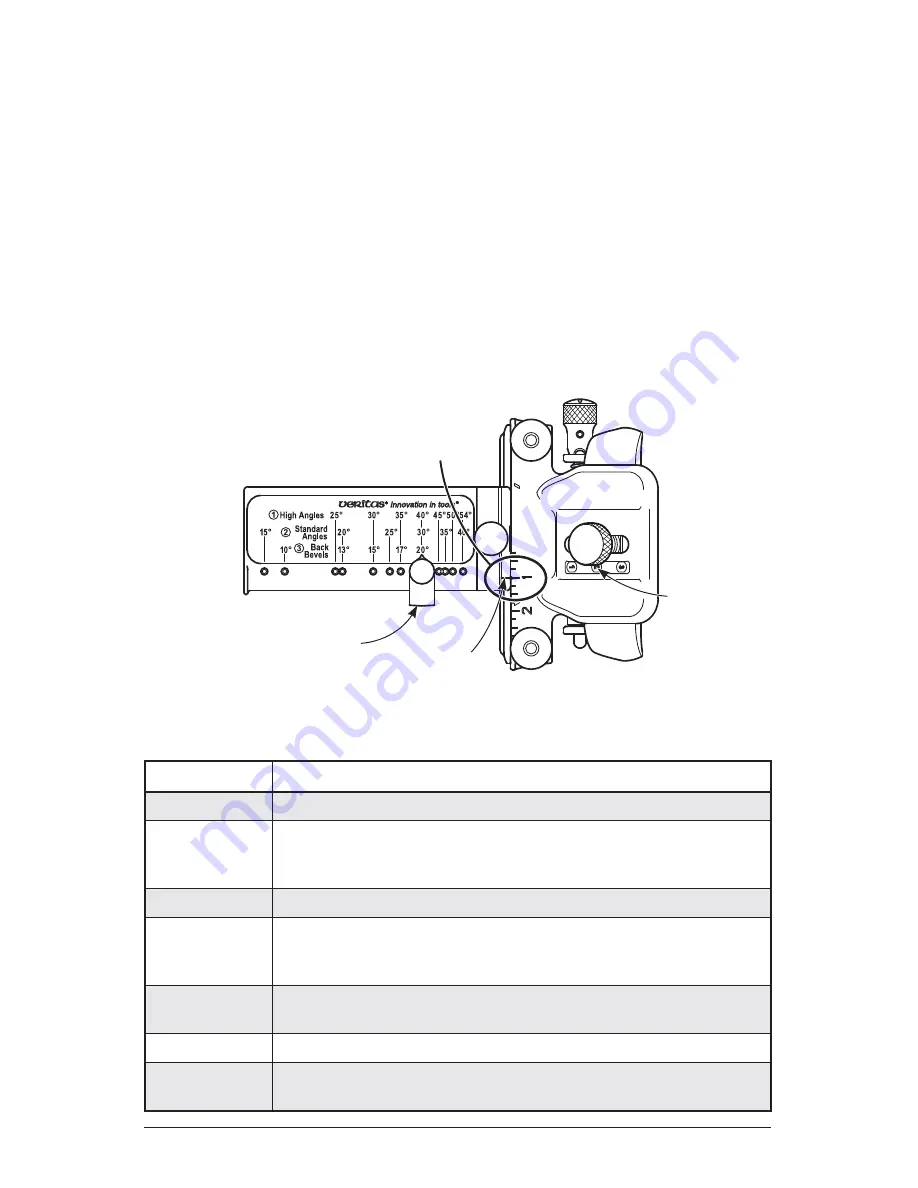

Step 3: Setting the Registration Jig

The registration jig ensures your blade is centered and squared in the blade carrier and

sets the blade projection for the desired bevel angle.

Slide the registration jig onto the dovetail feature along the front of the blade carrier.

Set the registration jig such that the pointer on the top jaw of the jig aligns with the

approximate width of your blade on the scale on the top of the blade carrier (see

Figure 4

). Tighten the registration jig clamp knob only fi nger tight. Do

not

overtighten

as it is desirable to have some up and down movement of the registration jig to allow

it to easily slide off the blade when loosened.

Set the registration stop to the desired bevel angle, aligning it with the scale of your

choice. The registration stop in

Figure 4

is set for a 1

"

wide blade and a 30° bevel

angle using the

d

(yellow) standard-angle confi guration.

Figure 4: Registration jig installed.

Bevel Angle Used on these tools

<15°

Back bevels.

15° to 20°

Paring chisels, skew chisels (including turning skews that

are bevelled both sides), low-angle planes for softwood,

skew-blade planes.

20° to 25°

All of the above (except skews) for hardwood or end-grain use.

25° to 30°

Chisels used both for paring and light mortising, firmer chisels

for softwood, most plane blades (smooth, jack, jointer, etc.),

and spokeshave blades.

30° to 35°

Mortise chisels, firmer chisels for hardwood, plane blades for

hardwood with pin knots.

35° to 40°

Mortise chisels for heavy use, particularly any with brittle steel.

>40°

Scraper plane blades and bevel-up smoothing planes used on

wood with difficult/reversing grain to produce Type II wood chips.

Registration stop set for 30°

(

d

yellow standard angles).

Pointer

Registration jig set

for 1

"

wide blade.

Blade carrier

positioned at

the

d

yellow,

standard-angle

setting.

4