Step 4: Installing the Blade

For reliable results, the blade

must

be properly installed in the guide.

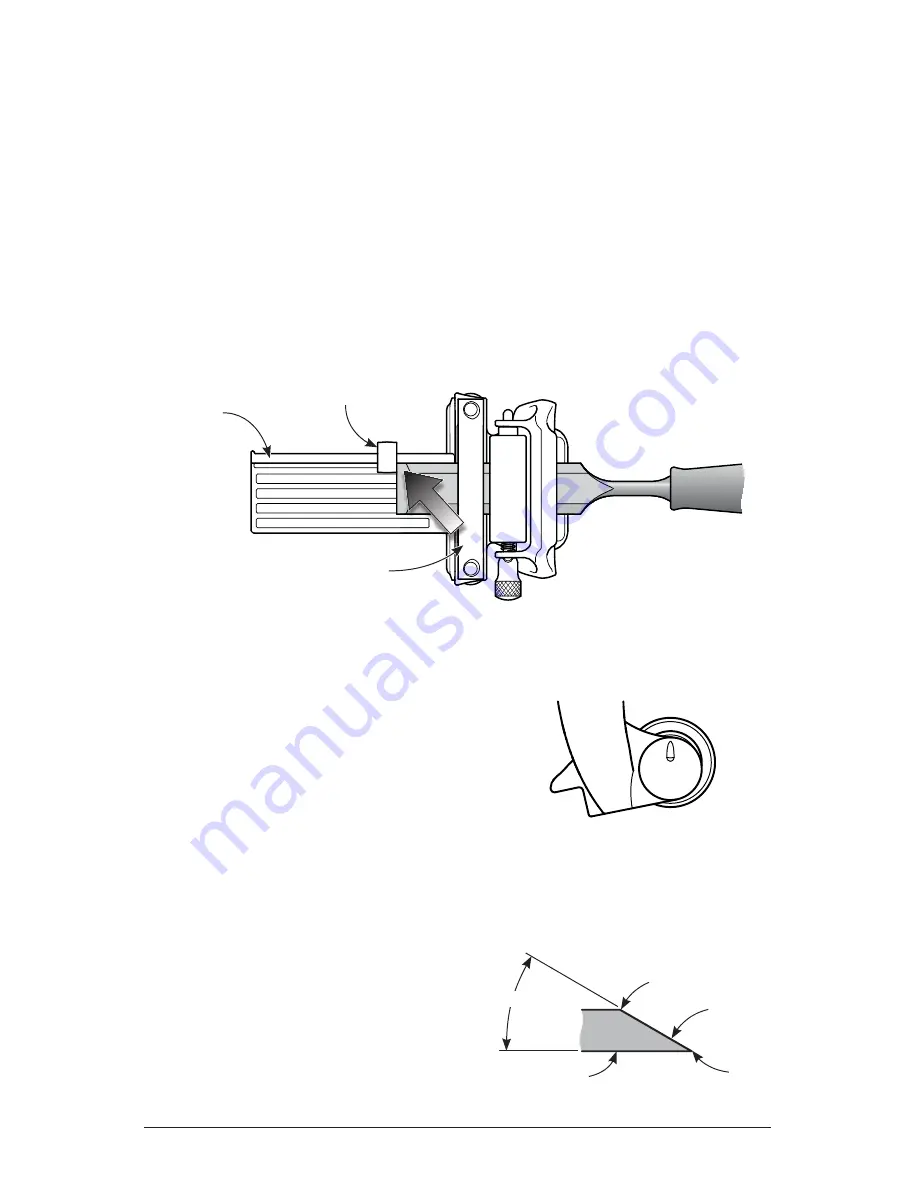

Loosen the two blade clamp knobs on the blade carrier. Open the clamp bar wide

enough to slide the blade in. The knobs

must

be loosened and tightened in

small

increments.

Do not

tighten or loosen one side substantially more than the other;

otherwise, the clamp bar or knobs may jam.

Hold the honing guide upside down, and slide the blade in the honing guide such that

it bears against the fence on the registration jig and just barely touches the blade stop

(see

Figure 5

). The blade will be centered in the honing guide. The resulting bevel

angle will be accurate, and the edge square to the side of the blade.

Hand tighten

the knobs fi rmly and evenly

. The clamp bar must be parallel to the upper jaw to

effectively secure the blade.

Loosen the registration jig clamp knob and slide the registration jig off of the blade

carrier. Check that the blade clamp knobs are still tight after removing the jig to ensure

the blade doesn’t inadvertently shift in use.

Step 5: Honing the Primary Bevel

Ensure that the micro-bevel knob is set to the

12 o’clock position (as shown in

Figure 6

). The

spring-loaded knob is easy to adjust by pulling

it out of the body just enough to allow rotation

of the pointer to the desired position.

Roll the guide and blade back and forth on the abrasive surface until a satisfactory

bevel is formed, ensuring that any downward force is applied mainly to the edge

of the blade. Since the roller maintains the

angle, it should be in contact with the stone

at all times. If the roller is lifted off the

stone, the very edge of the blade will have a

higher bevel angle than the one selected.

The primary bevel should extend at least

1

/

8

"

back from the edge.

Figure 5: Installed blade.

Figure 6: Micro-bevel knob set

for honing primary bevel.

Figure 7: Primary bevel.

Registration Stop

Fence

Clamp Bar

Heel

Face

Cutting

Edge

Primary

Bevel

30°

5