EUROBLOC

SERVICE MANUAL FOR HOIST

101/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

11

12

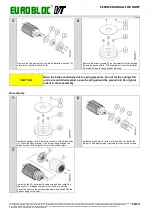

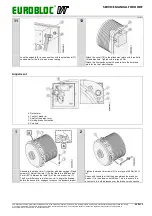

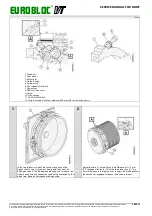

Lock the solenoid (8) in open position with the steel band (27)

used earlier for the test run and rope reeving.

Attach the cover (10) to the attachment plate with three bolts

(9) and washers. Tighten with a torque 6 Nm.

Attach the limit switch wire with a cable tie to the hoist end

plate for the final electrification.

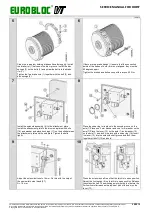

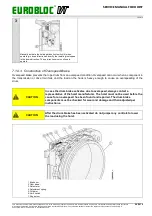

Adjustment

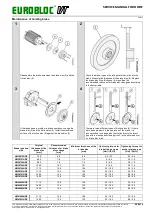

4. Detent arm

5. Teeth of brake rim

7. Shaft of the detent arm

6. Holding brake limit switch

8. Solenoid

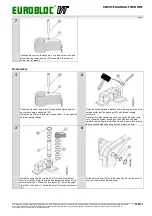

1

2

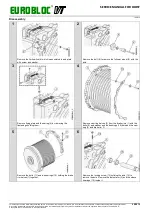

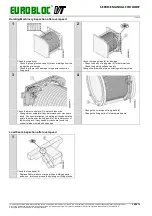

Assemble the brake rims (1) together with disc springs (2) and

screws (3). Adjust the rims (1) so that there is a difference of

5 mm (0.2”) between the teeth (5) of the two brake rims (1).

The 5 mm difference is to allow one rim to begin the braking

before the second rim engages to reduce the dynamic impact.

Tighten the brake rim screws (3) to a torque of 60 Nm (44 ft

lb).

Check with the caliper that the gap between the brake rim

halves (1) is the same on both sides. This is to ensure the

even tooth to tooth distances over the brake rim connection.