EUROBLOC

SERVICE MANUAL FOR HOIST

11/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

14

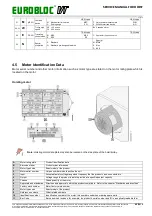

Beware of high temperature components

Some components of the product, such as the motors, can become very hot during use. Check

that components are cool before working on them.

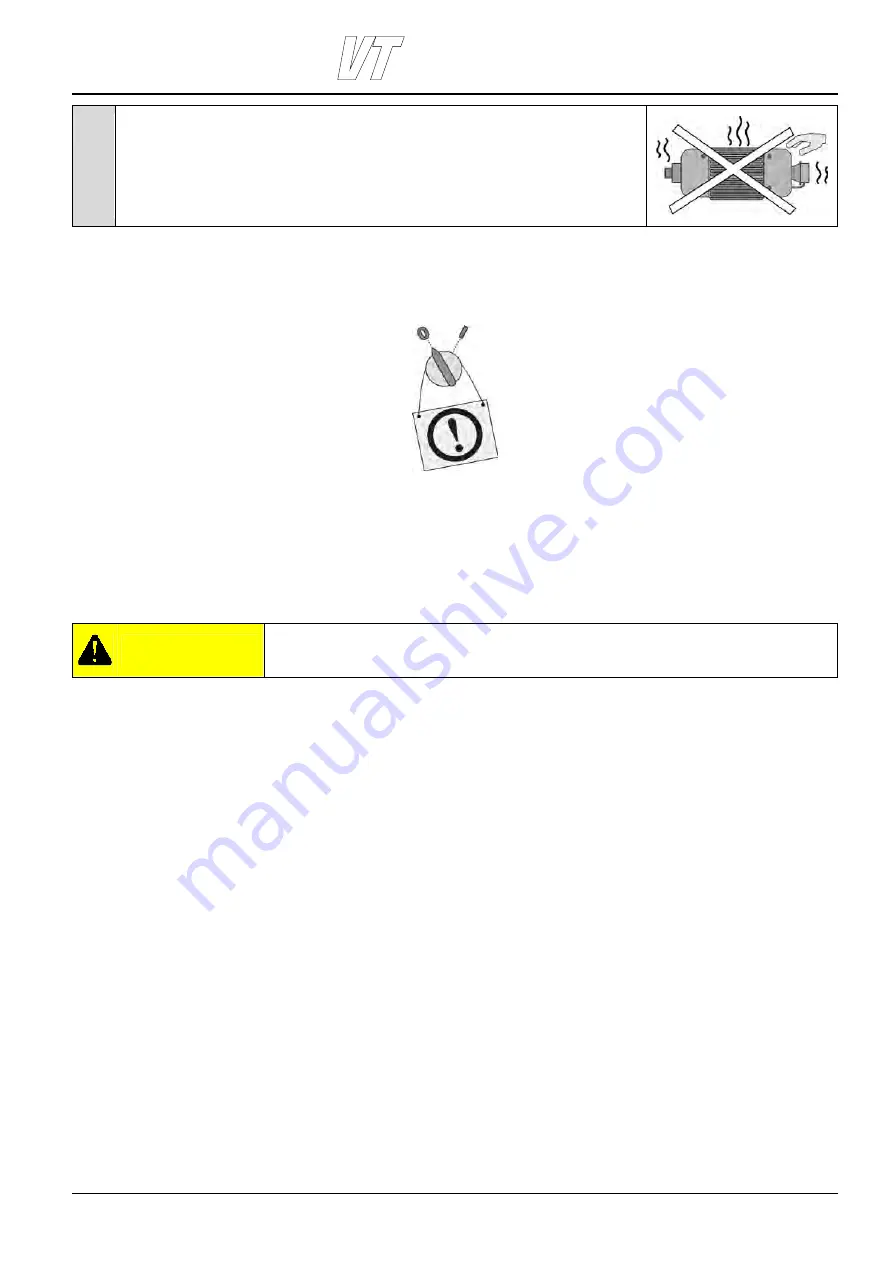

3.4.1 Lockout - Tagout Procedure

During installation, inspection and maintenance, lockout-tagout procedures must be followed in accordance with

local regulations and the documented site lockout-tagout policy. The owner must ensure that the operators are fully

aware of the applicable lockout - tagout practices.

Lockout-tagout procedures are primarily intended to protect personnel by preventing accidental starting or

exposure to electric shocks. Individual locks and tags are placed on controls to prevent their use until the person

who installed the lock or tag removes it.

CAUTION

Never attempt to operate a control, switch, valve or other device when it is

locked out or tagged out.

Items which are normally included in the documented lockout-tagout policy:

Communication requirements: who to inform before using lockout - tagout.

When the use of lockout - tagout is permitted.

Identification of each of the switches, controls, valves and other energy isolating devices present at the

site. The role of each device should also be explained.

The lockout - tagout sequences to be followed before, during and after maintenance.

Safety and operational considerations regarding other products on the same runway or on adjacent

runways.