EUROBLOC

SERVICE MANUAL FOR HOIST

111/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

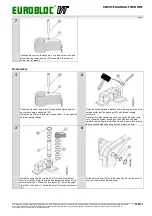

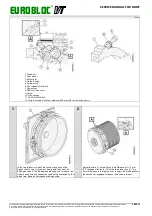

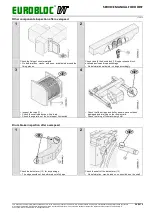

Detent arm

• Check that the arm (3) rotates easily on its shaft (14).

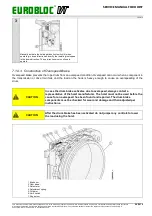

7.1.9.5 Service after an emergency braking – In case an Overspeed occurs

CAUTION

In case the drum brake activates due to overspeed, always contact a

representative of the hoist manufacturer. The hoist must not be used before the

cause for an overspeed has been found and repaired. The drum brake

components must be checked for wear and damage and then adjusted per

instructions.

CAUTION

Extreme caution must be taken and the load must be removed from the hook of

the hoist.

Overspeed Condition – Find Fault

Find the reason for drum brake emergency braking. An overspeed occurs because of a failure in the drive

transmission system of the hoist. Possibilities - The hoist brake has worn (steel on steel) / a coupling has sheared /

a gear in the gearbox has stripped / a drive shaft has broken.

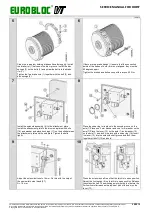

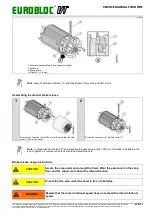

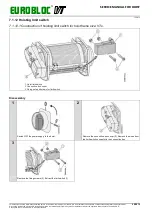

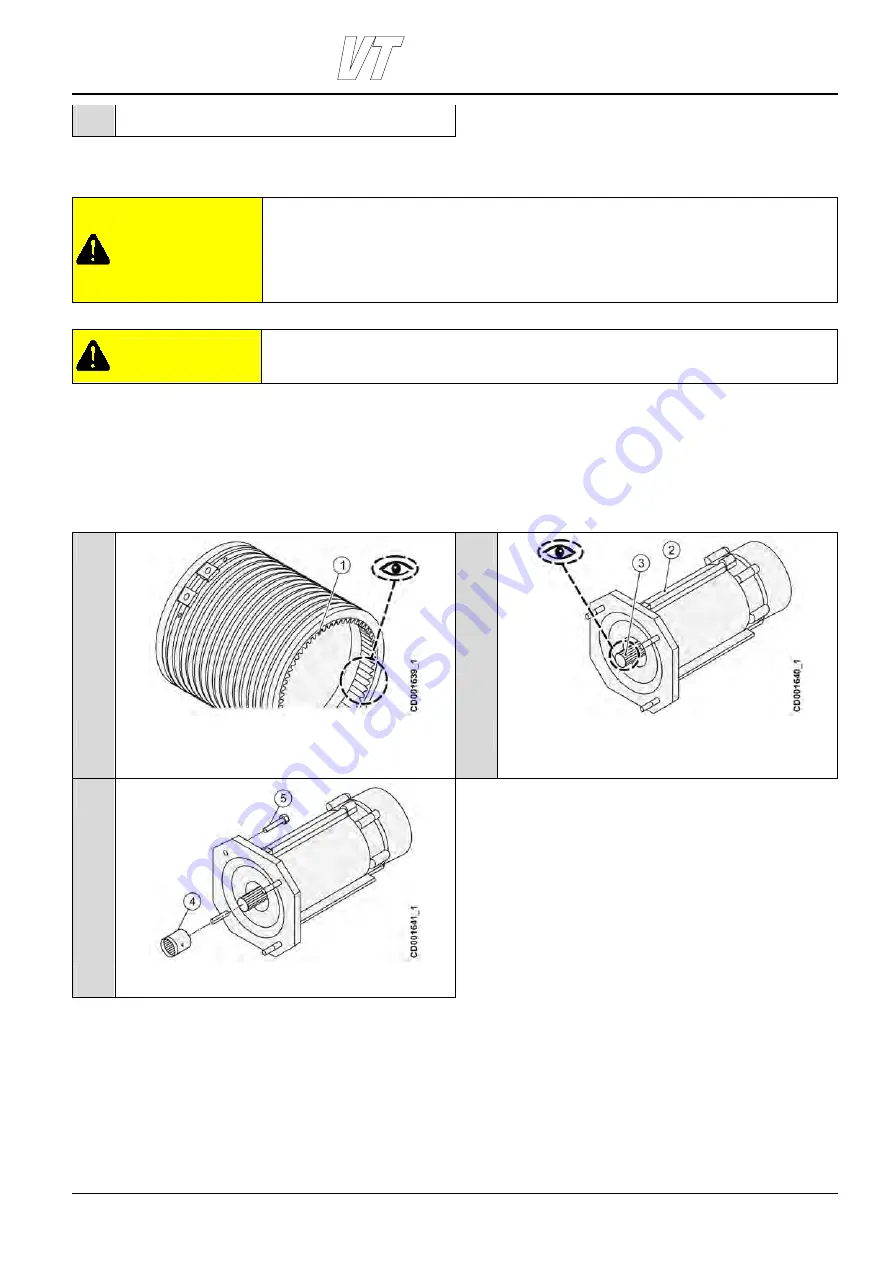

Hoisting unit inspection after overspeed

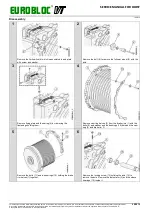

1

2

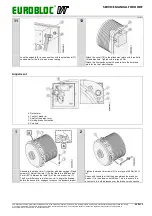

Check the condition of the hoisting gear and drum gear rim (1)

• No abnormal noises when driving.

• Check that the gear rim fitted inside the drum has not

slipped.

Disassemble motor (2) and check the condition of the spline

on the motor shaft (3) and on the gear primary shaft

• No deformations or broken teeth allowed.

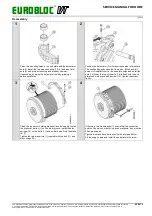

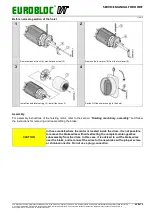

3

• Change the coupling (4) between the motor and gear.

• Change the motor fixing bolts (5).