EUROBLOC

SERVICE MANUAL FOR HOIST

112/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

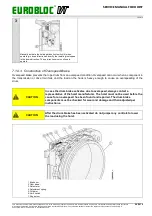

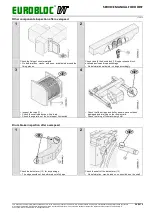

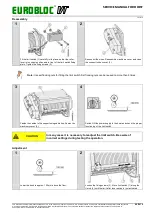

Hoisting Machinery inspection after overspeed

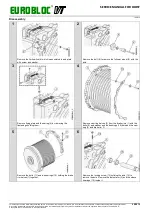

1

2

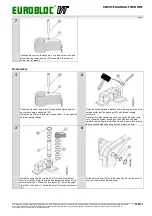

Check the rope drum

• Check the rope grooves visually for any markings from the

rope guide or wire rope.

• Check that there is no damage to rope end connection

fixing parts.

Check the rope guides (6) for damage

• Check the body of rope guide (6) for deformations

• Check the guiding surface visually.

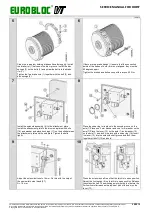

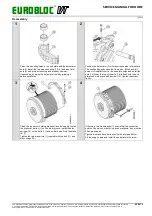

Change the drum end plate on hoisting machinery side.

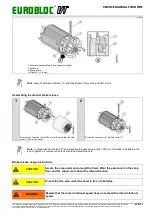

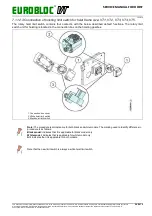

3

4

Check the drum end plate (7) on drum brake side

• Change drum end plate if any deformations or cracks are

found. Pay special attention to hoisting unit support plates

and to the area near the fixing point of the lower corner of

the hoisting unit. If any bends or cracks are found, the

support plates must also be changed.

• Change the hoisting unit fixing bolts (8).

• Change the fixing bolts of intermediate beams.

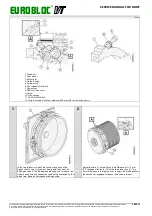

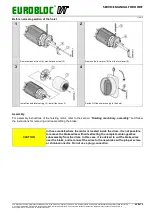

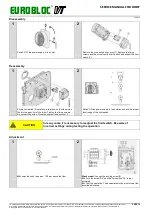

Load beam inspection after overspeed

1

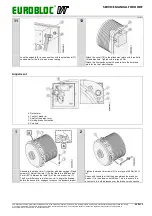

Check the load beam (9)

• Replace if deformations, cracks, broken welding seams,

and so on, are found around the hoisting unit fixing places.