EUROBLOC

SERVICE MANUAL FOR HOIST

146/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Normal condition

Pulley misalignment

Pulley too large for rope

Rope misalignment

Seized bearing

Overloading

Rope imprints can also be an indication that the hoist has been utilized beyond its design duty class

For measuring sheave groove wear and acceptance criteria, refer to “General Overhaul Instructions”.

7.2.5 Sheave support and rope anchorage support

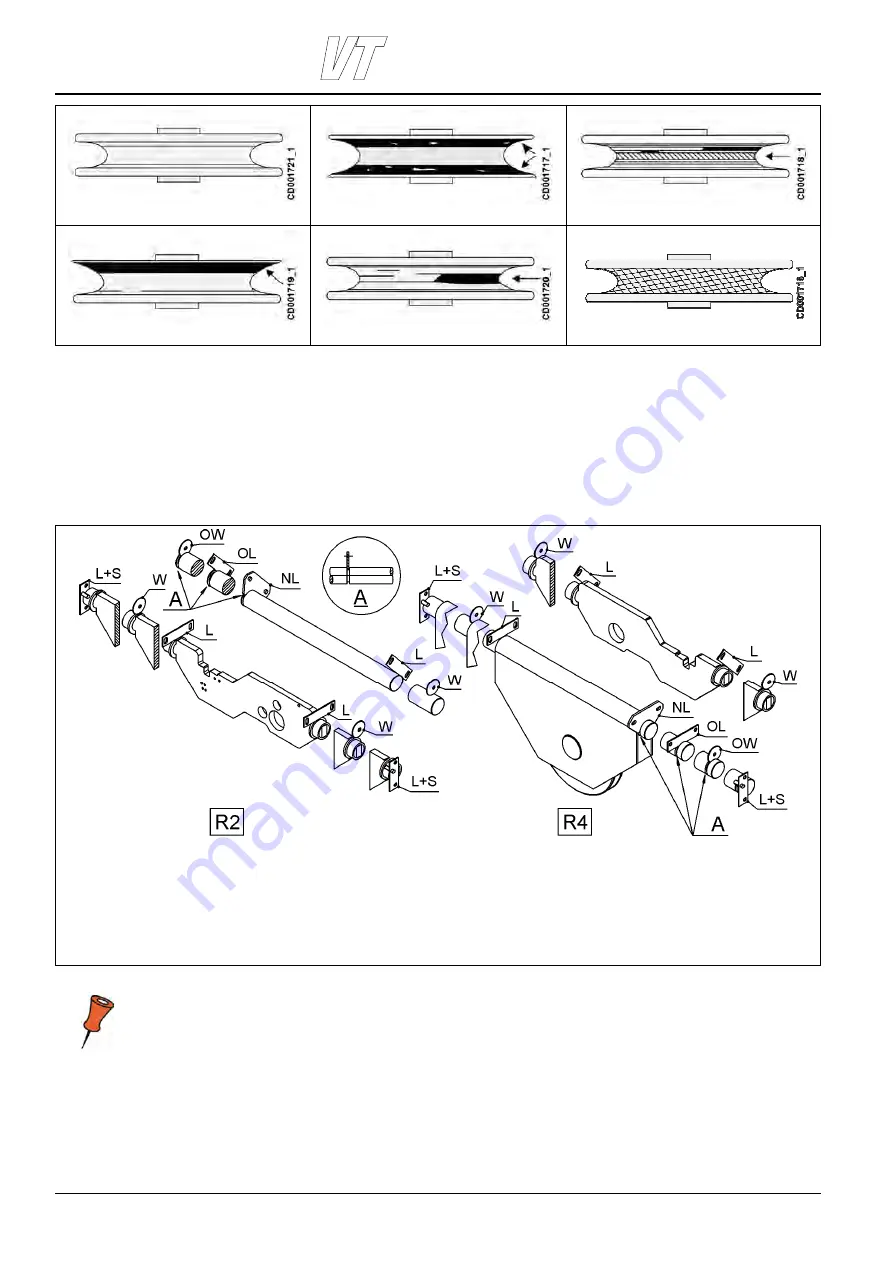

Support shaft locking, Low headroom trolley, and Normal headroom trolley. Reeving: 02 and 04.

L. Locking plate

W Locking washer

OW Old type washer

L+S Locking plate + locking screw

L. Locking plate

OL. Old type locking plate

NL. New type locking plate

W. Locking washer

L+S Locking plate + locking screw

Note: Replace locking washer (OW) or locking plate (OL) with the shaped locking plate (NL) if possible. Or

replace locking washer (W) with the locking plate (L) if possible.