EUROBLOC

SERVICE MANUAL FOR HOIST

200/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

1

Driving wheel

Idle wheel

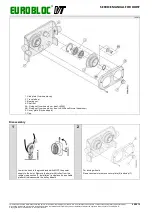

Inspect visually the condition of the trolley wheels. Change the trolley wheels if they are worn more than the wear limits given in the

following chapter “Wearing limits of under running trolley wheels”.

2

3

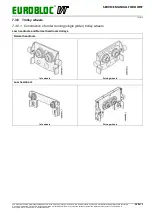

Check that the wheels of the trolley are correctly aligned.

Adjust alignment if necessary (see “Adjustment” below).

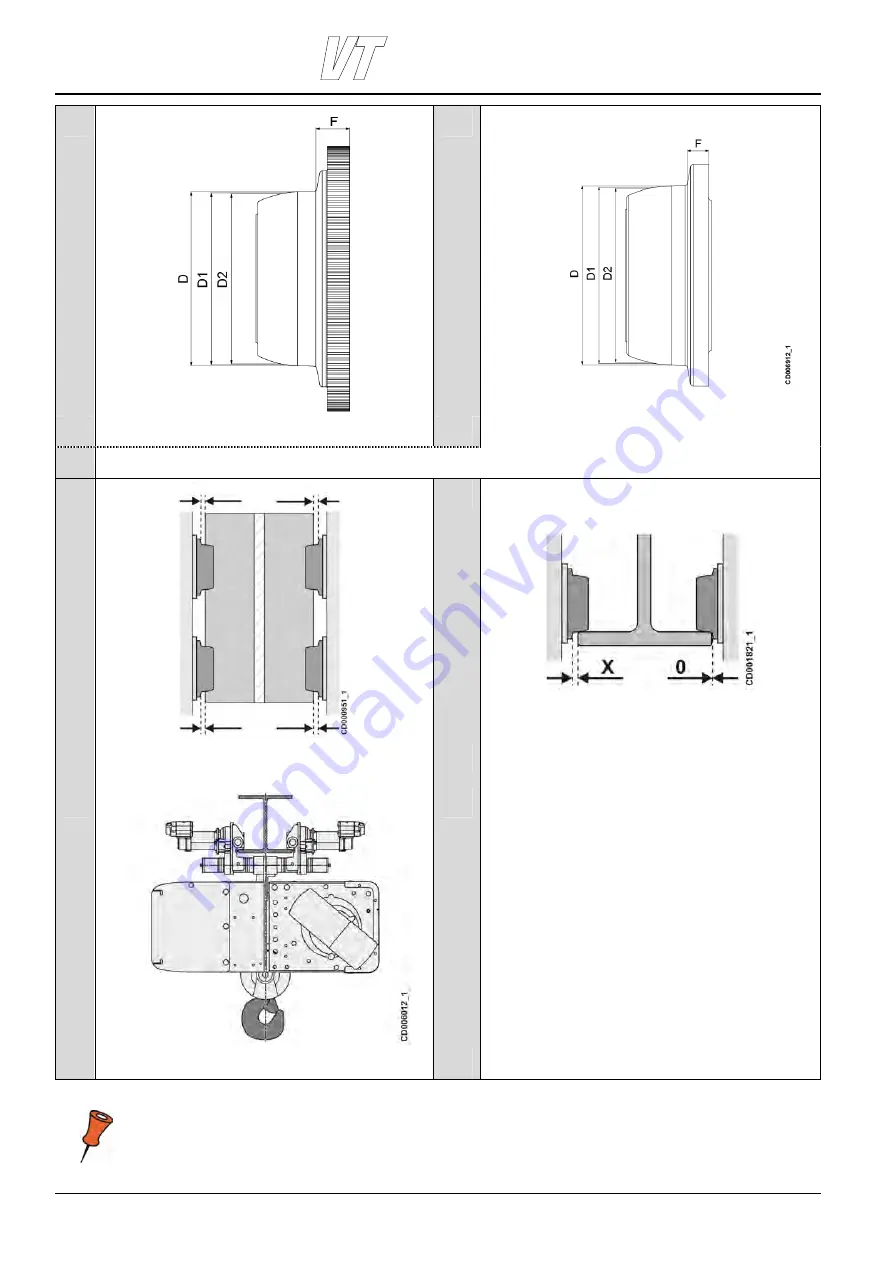

Adjust the side plate (5) of the trolley inwards until there is a

gap of approximately X = 3…5 mm between the wheel

flange and the flange of the beam.

4

Check that position of the trolley so adjusted that the hook is

hanging below the centerline of the beam.

Note: If the trolley is reassembled, the track width of the trolley must be properly adjusted.