EUROBLOC

SERVICE MANUAL FOR HOIST

26/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Hoisting limit

switches

Up Limit

Slow Down Up

Limit

Down Limit

Hook limit (Safety

Up Limit/ Ultimate

Limit)

10%

12

Verify the condition and operation of hoisting limit switches.

Operate the hoist in the up direction and slowly drive to the Up Limit

Switch Activation point. Check that it works.

Run the hook block down at a short distance and drive at high speed

and check if the Slow Down Up Limit activates to override the high-

speed command to slow down the speed before the Up Limit

activates.

Operate the hoist in the down direction and drive to the Down Limit

Switch Activation point.

Test the Hook Limit by hand actuation.

Adjust or replace parts as required.

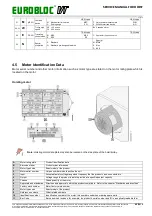

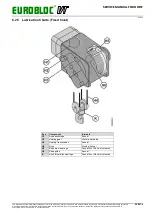

Construction of hoisting limit switch for

hoist frame size: VTs

Construction of hoisting limit switch for

hoist frame size: VT1, VT2, VT3, VT4,

VT5

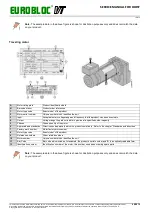

Maintenance task for hoisting limit

switch, hoist frame size: VTs

Maintenance task for hoisting limit

switch, hoist frame size: VT1, VT2,

VT3, VT4, VT5

Up Limit Distance

10%

12

Verify Up Limit Distance.

Verify the Up Limit Distance to the frame of the trolley. It is important

to adjust the C dimension according to the specification, to minimize

rope and sheave wear.

Down Limit

Distance

10%

12

Verify Down Limit Distance.

When the hook block is in the Down Limit Switch Activation point,

verify that there is a minimum number of wraps of rope on the drum

according to the standards (the absolute minimum is two full turns of a

rope).

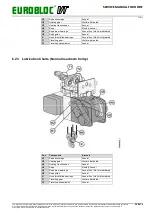

Overload

protector

10%

12

Inspect the condition and operation of the overload protector.

Mechanical switch and load sensor overload device:

Test the free movements of mechanical parts.

Test the mechanical overload limit switch by mechanically activating

the switch and checking for a click.

Clean and lubricate lever mechanism.

Verify that the set screw is locked in its place.

When required to confirm calibration, place a test weight of a nominal

load plus 10%. Adjust mechanical overload to stop hoisting at 110% of

capacity.

Replace damaged parts.

Power measurement overload device:

Conduct a test operation of the power measurement overload device

according to the local regulations if necessary.

Overload protection

Maintenance of overload device

Operation test of overload

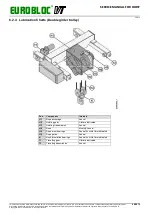

Condition

monitoring unit

10%

12

Verify the operation of the condition monitoring unit.

Test the condition monitoring unit by lifting a known load and verify

that the unit reads the load within 5% accuracy. If not reading

properly, a new calibration of the unit required.

Check for possible error codes and warnings.

Service manual for hoist control

device

Runway mechanical

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Crane runway rail

Inspect the crane runway rail.

• Check the bridge squareness

• Check that both end trucks are working simultaneously in the starting

and the stopping phases

• Monitor for possible sounds of grinding or any unsmooth travel of the

bridge along the runway

• Visually check the straightness

• Check rail fastenings randomly for possible loose connections

• Check the rail for any signs of wear.