EUROBLOC

SERVICE MANUAL FOR HOIST

28/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Bridge rail

sweeps

10%

12

Check the condition of bridge rail sweeps for any signs of wear and

replace them if necessary.

Bridge electrics

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Bridge travel

limits

10%

12

Check the operation of Slowdown and Stop Travel Limits of the

bridge.

Bridge power

supply

10%

12

Check the festoon cable system.

• Check that the cable is not worn

• Verify that the cable is running smoothly from one end of the bridge to

the other end, indicating that the cable carrier is not damaged and the

cable is not running into any obstacles

• Check that the pull cable is secure and working properly, relieving strain

on the cable when the trolley is pulling

• Check that the festoon arm is secure.

Bridge disconnect

switch

10%

12

Verify that the bridge disconnect switch on the bridge panel turns on

and off the power.

Electrics

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Emergency stop

10%

12

Check that the emergency button is clean and not damaged.

Push in the emergency button. Test that no movement activates. Verify

that the main contactor is off.

If the emergency stop is equipped with key locking, remove the key and

test that it is not possible to release the emergency stop.

Main switch for

hoist

10%

12

Check that the main switch is clean, clearly marked and not

damaged.

Test manually that the main switch switches off the hoist.

Main isolation switch

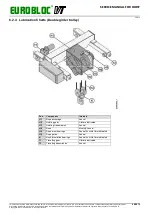

Wiring

10%

12

Inspect the condition of wiring and the connections.

• Follow the power supply and visually check the potential areas for

damages

• Pull on the wiring at the terminals

• Check the wiring for any signs of wear, crushing, breaks, or cuts

• Check visually that the cable bushings are tight

• Check visually that the connectors are not damaged

• Test by hand that the cable bushings are tight

• Test by hand that the connectors are tight

• Check randomly the tightness of screws at the terminal blocks and at

the connections of other components.

Note that the terminals can cause a heat damage to the insulation and/or

to the connections.

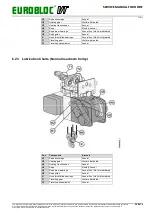

Hoist cubicle

10%

12

Check that the electrical cubicle is securely fastened with a trolley or

a bridge.

Verify that the doors are closing properly and the locking devices are

functioning. Check the door sealing.

Check that the cubicle is clean.

Inspect the air conditioning and filters.

Inside the electrical cubicle:

• Check that the electrical components and their fastenings are secure.

• Check that all the electrical protection guards are in place.