EUROBLOC

SERVICE MANUAL FOR HOIST

32/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Wire rope

10%

12

Inspect the condition of the rope.

Inspect the rope for

• broken wires

• kinks

• wear

• dryness (lubricate if necessary).

Wire rope

Maintenance of wire rope

Replacing the wire rope

Discard criteria of wire rope

Lubrication

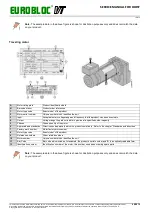

Rope anchorage

on drum

10%

12

Inspect the condition and correct position of a rope anchorage.

Check that the rope clamp nuts are tight.

Ensure that the rope has not slipped in the rope anchorage by comparing

to the nominal measurements.

Make sure that the rope end protrudes from the rope anchorage as

specified.

Inspect the condition of the wire rope near the rope anchorage.

Inspect the anchorage shaft locking.

Rope anchorage

Inspections and criteria for rope

anchorage

Rope anchorage

on dead end

10%

12

Inspect the condition of a rope sheave support and a rope anchorage

support.

Check that the sheave support shaft(s) are correctly in their slots and

correctly locked.

Lubricate the pivot bearing surfaces of the rope anchorage if needed.

Ensure that the rope is assembled inside the rope anchorage correctly.

Check that the wire rope clips have correct tightness and proper

orientation.

Rope reeving

10%

12

Inspect the rope reeving assembly.

Lift up the hook and lower it down. Pay attention to the following issues:

• Check if the hook block tries to rotate (remove the rotation by

reassembling the end fixing and by rotating to the opposite direction)

• Inspect that the reeving balancing tilts freely (in two rope systems)

• Verify that the rope moves smoothly over all sheaves and trough the

rope guide

• Ensure that the rope is tight and properly laid on drum grooves.

In true lift hoists, it is normal that the hoisting causes the hook block to

rotate.

Rope reeving system

Rope sheaves

(upper sheaves)

10%

12

Inspect the condition of rope sheaves.

Measure the rope sheaves to check if any wear.

Inspect during operation if any unusual sound is coming from sheave

bearings.

Check the condition of the rope sheave support structure.

Check that the sheave support shafts are correctly in their slots and

correctly locked.

Inspect the sheave support shaft fixing plate for any cracks (some Low

Headroom Trolley models).

Replace the support shaft by the latest construction/parts if not done yet

(some Low Headroom Trolley models).

Wear inspection of sheaves

Maintenance of rope sheaves

Sheave support and rope anchorage

support

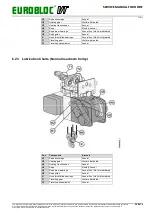

Hook block

10%

12

Check the operation and condition of the hook block.

Check the following:

• The labels/stickers exist and are readable

• The covers are not bent or damaged and do not touch to sheaves or

rope

• Lubricate all lubrication points.

•

Lift an empty hook and test that:

• The hook does not rotate.

• The empty hook does not tilt.

•

Test that the rope runs smoothly on sheaves with and without load.

Hook block

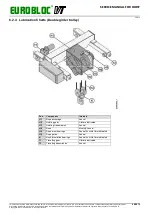

Cross bar

10%

12

Check the condition of the cross bar hinge by tilting the hook forging.

Check the condition of the hook thrust bearing by rotating the hook

forging.

Lubricate the cross bar hinge bearings using the grease nipples

(hinged cross bars only).

Lubricate the hook thrust bearing using the grease nipple, or open

the cross bar if there is no grease nipple.

Lubrication

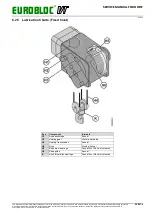

Hook safety latch

10%

12

Test by hand that the safety latch is not damaged and the spring

keeps it closed.