EUROBLOC

SERVICE MANUAL FOR HOIST

33/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

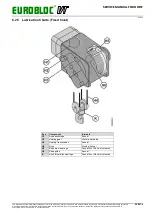

Hook latch trigger

(magnet

operated)

Test the operation of the latch trigger. Adjust the trigger play (movement)

with the adjustment screw if necessary.

Clean the magnet when dirty.

Hook block

Hook forging

10%

12

Inspect the condition of hook forging.

Measure the hook forging opening if needed.

Hook opening

Trolley wheels

10%

12

Inspect the condition and cleanliness of trolley wheels.

Check the trolley wheels for possible wear in the trolley wheel surfaces

and flanges.

Check the adjustment of rail width or rail gauge and measure.

Clean the wheel and its running surfaces from grease and oil.

Replace the worn parts.

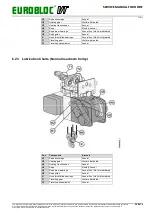

Construction of single girder trolley

wheels

Construction of double girder trolley

wheels

Maintenance of single girder trolley

wheels

Maintenance of double girder trolley

wheels

Wearing limits of single girder trolley

wheels

Wearing limits of double girder trolley

wheels

Test trolley wheel operation.

Drive the trolley with and without load. Pay attention to the running sound

of bearings. If necessary, lift the trolley and test by hand the free and

smooth rotation of trolley wheels.

Check that the wheels are correctly aligned and inspect for possible wear

that is caused by misalignment.

Lubricate the bearings if needed and possible.

Trolley rail

sweeps

10%

12

Check the condition of trolley rail sweeps for any signs of wear and

replace them if necessary.

Load carrying

structures

10%

12

Check the condition of bolted joints and load carrying structures.

Visually check the bolted and welded connections of the security and

backup components like a derailment catch.

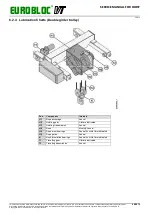

Trolley

Maintenance of double girder trolley

structures

Maintenance of single girder trolley

structures

Anti-collision devices

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Photoelectric anti-

collision device

10%

12

Inspect the condition and operation of the photoelectric anti-collision

device.

Clean the optical interfaces.

Check the screw connections.

Check the plug-in connections.

Inspect the operation of the photoelectric anti-collision device.

Ultrasonic anti-

collision device

10%

12

Inspect the condition and operation of the ultrasonic anti-collision

device.

Clean the sensor off thick layers of dirt and caked-on dirt.

Inspect the operation of the ultrasonic anti-collision device.

Controls

Component

In

te

rv

a

l

Inspection and maintenance task

Interval is SWP% reduction or calendar months

See further instructions

Pendant

10%

12

Check the condition and functionality of push buttons and switches.

Check all markings and signs that they are readable.

Drive all movements. Test all functions.

Change buttons/joystick or the whole pendant if needed.