EUROBLOC

SERVICE MANUAL FOR HOIST

36/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

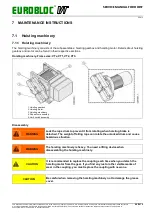

8

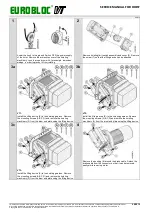

All slide bearings must be depressurised for the grease to be able to penetrate.

9

While lubricating, check the functioning of the bearings and observe whether there is any bearing

slackness.

10

The specified lubrication periods apply in favourable conditions and normal use. More frequent

lubrication is recommended in more demanding conditions and in heavy use, particularly of the

slide bearings.

11

Verify that the gear teeth of the open gear transmission are entirely lubricated.

Note: Do not use excessive lubricant. Excessive grease may cause bearing to overheat and reduces the

lifetime of the bearings.

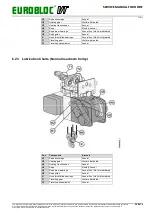

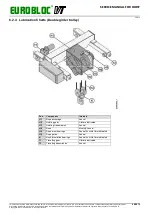

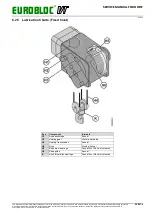

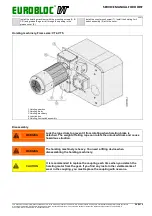

6.2.2 Lubrication Charts (Low headroom trolley)

Pos.

Component

Intervals