EUROBLOC

SERVICE MANUAL FOR HOIST

56/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

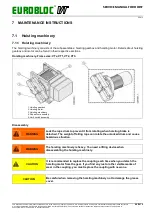

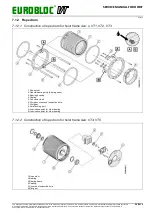

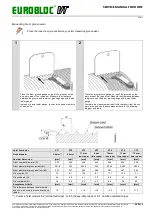

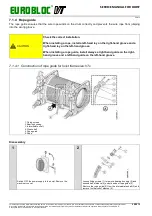

Measuring drum bearing running surface wear (drum frame size: s, VT1, VT2, VT3)

Hoist frame size

VT1

VT2

VT3

VT3

Rope diameter

6.4 mm**

8.0 mm

11 mm

(one rope)

8 mm

(two ropes)

Acceptance criteria

[mm]

[mm]

[mm]

[mm]

The clearance between the drum bearing groove

gauge and the bearing running surface

<0.2

<0.2

<0.2

<0.2

**) In some hoist models 6.2 (old default rope) or 6.5 (heavy-duty rope) or 6.7 (rotation resistant rope).

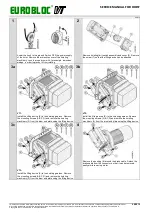

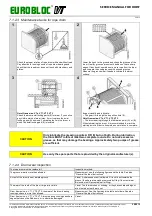

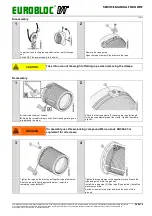

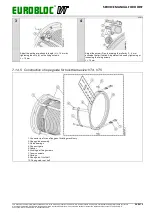

7.1.3 Rope clamps

The rope is fixed to the rope drum with rope clamps. The number of rope clamps varies with the type of hoist.

WARNING

In addition to the clamps on the rope ends, there must always be at least two

full turns of rope on the drum when the hook is at its lowest position in order

to provide friction.

CAUTION

For hoist frame size VTs there must always be at least five full turns of rope on

drum when hook is at its lowest position in order to provide fiction and

prevent interference between rope guide and clamp.

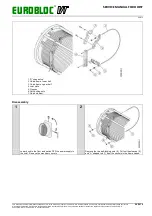

1. Rope

2. Rope drum

3. Rope clamps

4. Friction wraps (at least two full wraps)