EUROBLOC

SERVICE MANUAL FOR HOIST

59/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

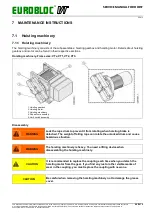

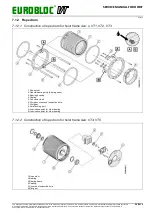

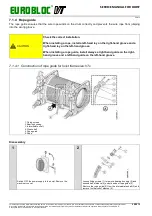

Reassembly

1

2

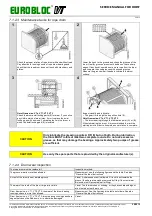

Put the rope guide (5) on the intermediate beams (3) placing

the first half of bearing sleeves (4) between the rope guide (5)

and the intermediate shaft (3). Put the second half of bearing

(4) to the upper intermediate beam and install the bearing

housing (2) and the fixing screws (1). Do the same to lower

bearing.

Switch ON the power supply to the hoist, test the rope guide,

and install the machinery covers.

Note: One of the three screws is longer than others; the longest screw must be located closest to the drum.

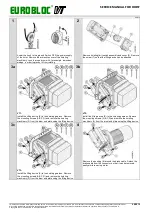

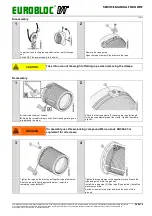

CAUTION

Tighten the fixing screws and fixing nuts on all rope guides to the correct

tightening torque. Refer to the section “Appendix: Tightening torques”.

Inadequate or exceeded tightening may cause rope guide to failure in

operation.

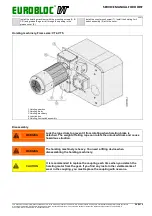

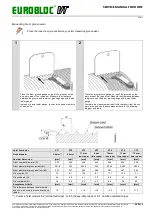

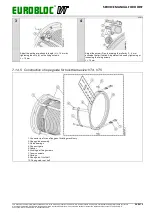

7.1.4.2 Construction of rope guide for hoist frame size VT1, VT2, VT3

1. Rope guide

2. Roller spring

3. Pressure roller

4. Connector rod for end flanges of hoisting machinery (drum flange connector rod)