EUROBLOC

SERVICE MANUAL FOR HOIST

88/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

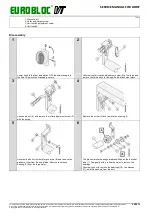

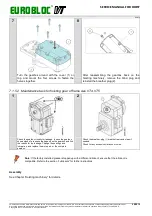

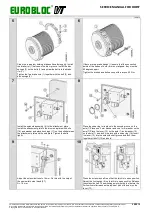

1a

1b

Motors without a separate coupling sleeve:

You should measure the shaft end eccentricity before

installing a new encoder if the previous encoder has been

damaged and no reason for the damage known.

The eccentricity (A) of the rotor surface in relation to the

bearing surfaces must not be greater than 0.03mm. If the

eccentricity of the shaft end is greater than 0.03mm, the shaft

rotor must be straightened.

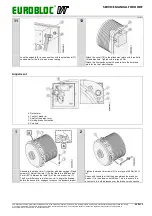

Motors with a coupling sleeve:

The coupling sleeve becomes an extension shaft for the

encoder when it is mounted onto the motor shaft.

You should measure the eccentricity before installing a new

encoder if the previous encoder has been damaged and no

reason for damage known.

Before mounting the coupling sleeve, the eccentricity of the

rotor surface in relation to the bearing surfaces must not be

greater than 0.03mm. Same eccentricity limit applies for the

shaft end.

After mounting the coupling sleeve, check the eccentricity of

this extension shaft. Maximum allowed eccentricity (A) for the

shaft is 0.05mm. If the extension shaft eccentricity is greater

than 0.05mm, it has to be straightened, remounted, or

changed.

The extension shaft must not be straightened without

confirming first that the motor shaft end eccentricity is

max 0.03mm.

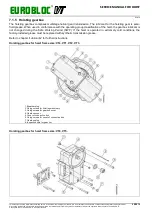

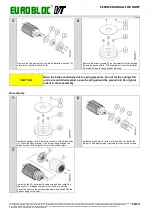

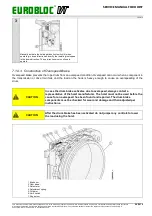

2

3

Install the support to the encoder.

The support (A) is not pre-installed on the encoder (B) by the

manufacturer. It is mounted with three screws and serrated

washers. Tightening torque for the screws is 2.5 Nm.

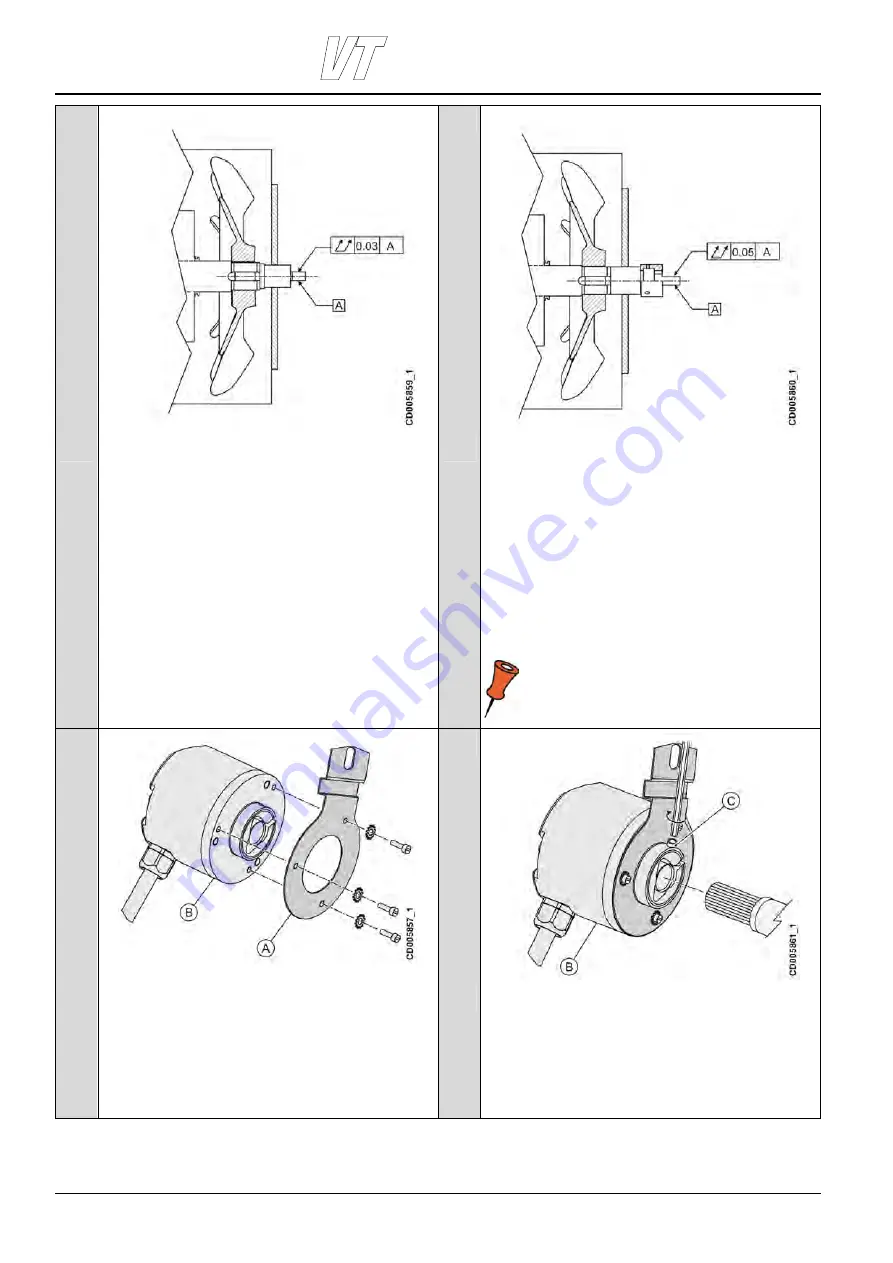

Install the encoder onto the motor shaft/extension shaft

manually.

The encoder (B) is installed in such way that the shaft goes all

the way into the encoder. After this, the encoder is pulled out

1…2 mm.

The encoder is firmly attached to the shaft by tightening the

encoder collar screws (C) with key SW2. Tightening torque is

1.5 Nm. Use also a thread-locking compound (soft or medium,

which enables also reopening) to secure the tightening.