EUROBLOC

SERVICE MANUAL FOR HOIST

94/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

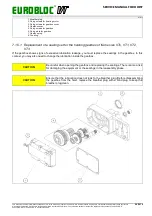

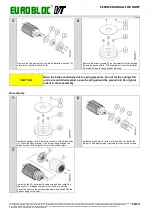

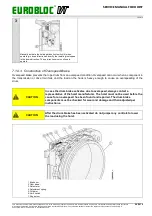

CAUTION

Friction material of NM409 brakes (red stamp: RSM-X) is different from the

NM387 series brakes (red stamp: RSM-H or RSM). These brake discs must not

be mixed.

CAUTION

Do NOT use any lubricant with brake disc teeth. This may cause brake

malfunctioning.

NOTICE

Friction disc is not used in MF13 type motors.

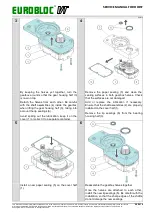

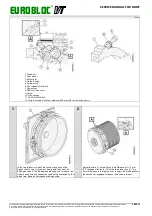

3

4

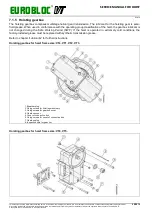

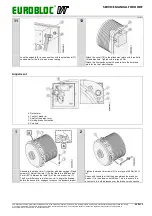

The friction disc (6) must be smooth with no grooving for

proper braking. Replace the friction disc if there is grooving on

its surface or it is bent more than 0.05 mm.

Check the physical condition of teeth on the brake disc (4). If

any visible wear is found in any of the teeth, replace the brake

disc with a new one.

Note that lubricant shall not be used.

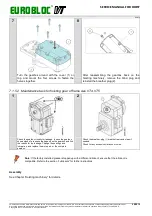

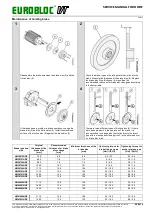

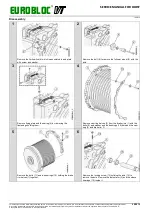

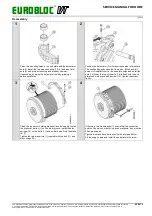

7.1.8 Second brake, Frame size: VTs, VT1, VT2, VT3.

The second brake (1) is an electromagnetic safety brake, which is closed by spring force. The second brake

operates as holding brake when the motion has stopped and the main brake has closed.

The second brake closes with a small delay and opens simultaneously with the main brake.

The second brake is attached to the primary shaft of the hoisting gear (2), whereas the hoisting motor (3) with the

main brake is attached to the other end of the shaft.