EUROBLOC

SERVICE MANUAL FOR HOIST

96/212

This document and the information contained herein, is the exclusive property of Verlinde S.A.S. and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of Verlinde S.A.S.

Copyright © (2013) Verlinde S.A.S. All rights reserved.

06/2015

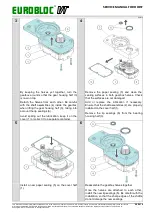

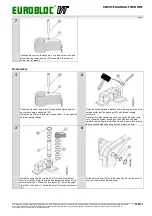

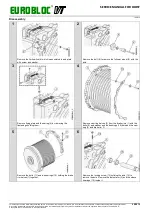

Reassembly

1

2

Install the pinion (7) and secure in place with the snap ring (6).

Install the brake disc (4), friction disc (5) and the brake (1) and

secure it with screws.

Remove the wedge locking the drum. Install the protective

cover to the hoisting machinery and switch ON the power

supply to the hoist.

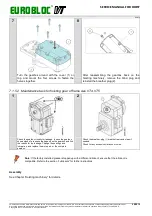

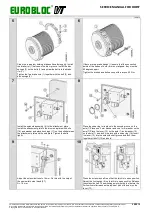

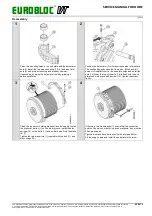

7.1.8.1 Maintenance of second brake

1

2

Disassemble the brake and clean the brake disc (4) and the

friction disc (5).

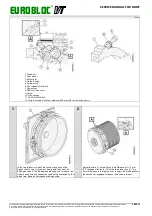

Check the brake type on the rating plate that is fixed to the

brake. Measure the thickness of the brake disc (5).

Replace the brake disc if the thickness (t) is less than the

minimum thickness as according to the table below.

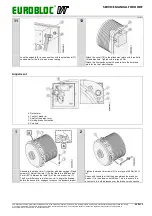

CAUTION

Check the oil leakage. There must not be any oil leakage from the gear box to

the brake.

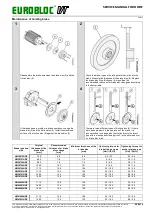

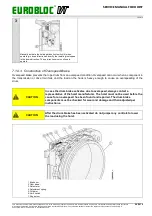

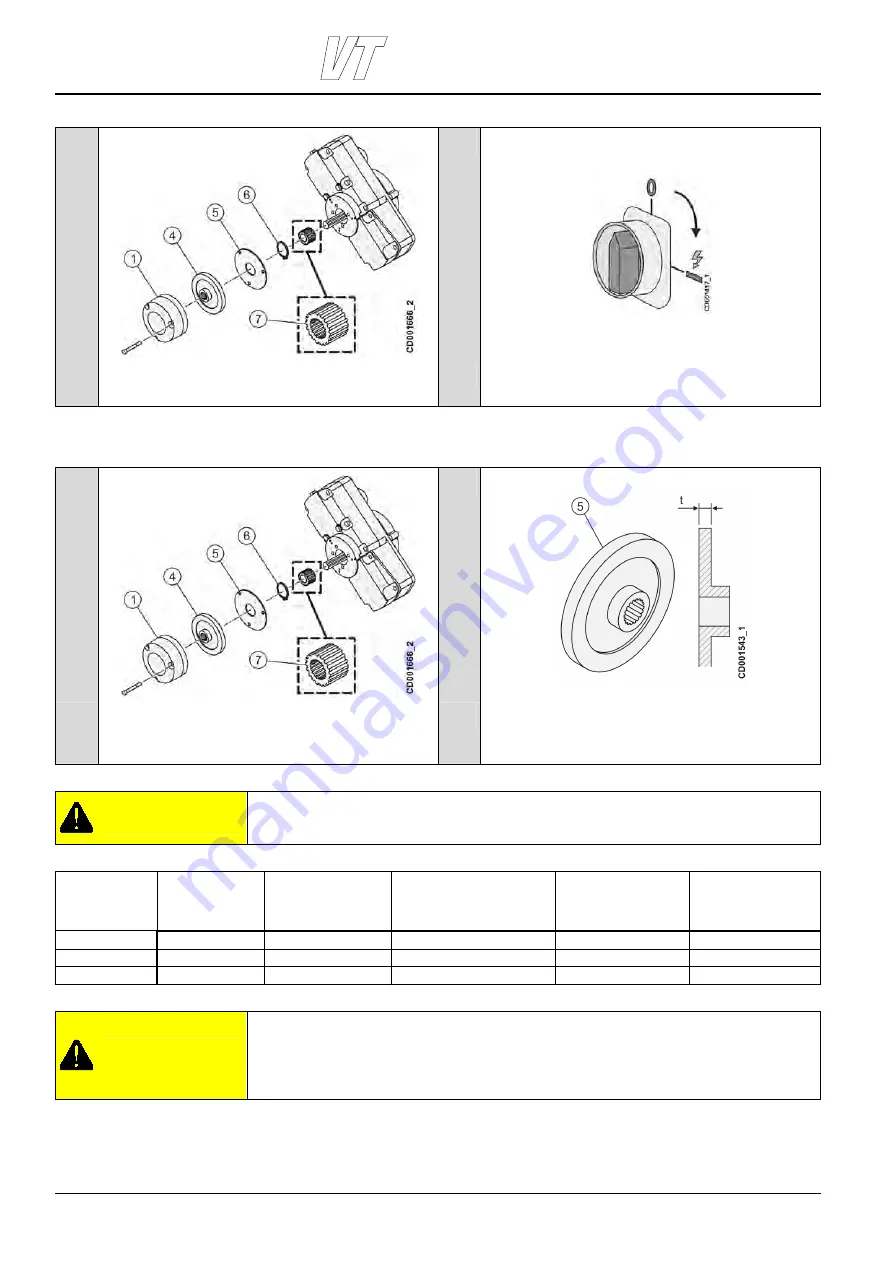

Brake type and

size

Original

thickness of the

brake disc

[mm]

Recommended

thickness for brake

disc change

[mm]

Minimum thickness of the

brake disc

[mm]

Tightening torque for

brake fixing screws

[Nm] / [lbf.ft]

Tightening torque for

anchor plate screws

[Nm] / [lbf.ft]

NM39330NR#

10.40

10.2

10.1

9 / 6.6

2.0 / 1.5

NM39340NR#

11.15

10.6

10.4

22 / 16.2

3.5 / 2.6

NM39351NR#

14.00

13.4

13.2

22 / 16.2

8.0 / 5.9

CAUTION

Friction material of NM409 brakes (identified with the manufacturer’s red

stamp: RSM-X) is different from the NM387 series brakes (identified with the

manufacturer’s red stamp: RSM-H or RSM). These brake discs must not be

mixed.