4

Defiant

®

1975CE Non-Catalytic / Catalytic Woodburning Stove

30005554

SaFeTy NoTice: iF yoUR DeFiaNT iS NoT pRopeRly

iNSTalleD, a hoUSe FiRe May ReSUlT. To ReDUce

The RiSk oF FiRe, Follow The iNSTallaTioN iN-

STRUcTioNS. coNTacT local bUilDiNg oR FiRe

oFFicialS aboUT ReSTRicTioNS aND iNSTalla-

TioN iNSpecTioN ReqUiReMeNTS iN yoUR aRea.

Before you begin an installation, be sure that:

•

Your stove and chimney connector will be far enough

from combustible materials to meet all clearance

requirements.

•

The floor protector is large enough and is constructed

properly to meet all requirements.

•

You have all necessary permits from local authori-

ties.

Your local building official is the final authority for approv-

ing your installation as safe and determining that it meets

local and state codes.

The metal label permanently attached to the back of

every Vermont Castings’ stove indicates the stove has

been tested to current standards. The test standard is

EN1340:001 + A:004 for Europe. Clearance and

installation information also is printed on the label. When

the stove is installed according to the information both on

the label and in this manual, local authorities in most cases

will accept the label as evidence that the installation meets

codes and can be approved.

However, codes vary in different countries. Before starting

the installation, review your plans with the local building

authority. Your local dealer can provide any additional

information needed.

iMpoRTaNT: FailURe To Follow TheSe iNSTalla-

TioN iNSTRUcTioNS May ReSUlT iN a DaNgeRoUS

SiTUaTioN, iNclUDiNg a chiMNey oR hoUSe FiRe.

Follow all iNSTRUcTioNS exacTly, aND Do NoT

allow MakeShiFT coMpRoMiSeS To eNDaNgeR

pRopeRTy aND peRSoNal SaFeTy.

all local regulations, including those referring to na-

tional and european standards, need to be complied

with when installing this stove.

installation

outside air

In some modern, super-insulated homes, there is inad-

equate air for combustion because of insufficient air infil-

tration into the building. Such air enters a home through

unsealed cracks and openings. Exhaust fans for kitchen

or bath can compete with the stove for available air and

compound the problem.

When poor draft is caused by a low infiltration rate, open-

ing a ground floor window on the windward side of the

house and in the vicinity of the stove will usually alleviate

the problem.

For appliances with power outputs above 5 kW, a perma-

nently open air vent is required by Section of Document

J. Air inlet grilles should be positioned so that they will not

be blocked. Refer to local and national codes for recom-

mended configurations.

Pressure variations within the house do not affect a stove

equipped with an outside air supply, and improved stove

performance often results. An Outside Air Adapter Kit for

the Defiant is available from your local Vermont Castings

dealer.

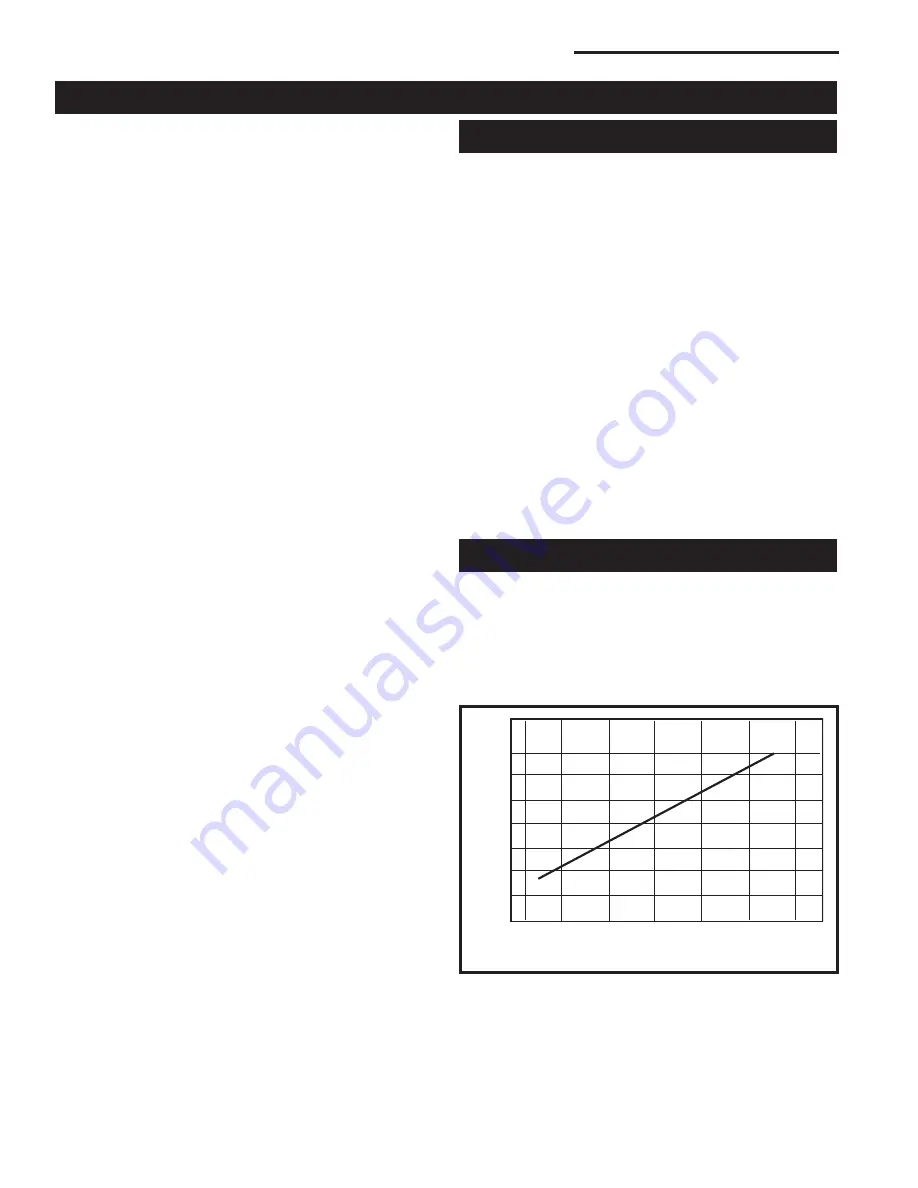

chimney height

Altitude affects chimney performance. When using a 8”

flue collar on the Defiant, refer to Figure for suggested

chimney heights at various altitudes. Chimney height

should be measured from the flue collar to the top of the

chimney. The recommended minimum chimney height is

4.9 m (16’).

30

25

20

15

0 2000 4000 6000 8000 10000 12000

Height

Altitude

ST491

Defiant

chimney height

11/2/00 djt

ST491

Fig. 2

Chimney height requirements for Defiant when equipped

with a 03 mm (8”) chimney.