0

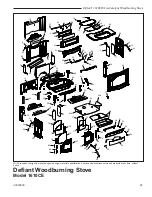

Defiant

®

1610CE Non-Catalytic Woodburning Stove

30003846

they must turn, it leaves some pipe in the room for heat

transfer, and it gives you long-term flexibility for install-

ing a different stove without relocating the thimble.

There should be no more than eight feet of single-wall

stove pipe between the stove and a chimney; longer

runs can cool the exhaust enough to cause draft and

creosote problems. With prefabricated chimney, bring it

down to six to eight feet from the stove. With a masonry

chimney, arrange the pipe so that it turns into the chim-

ney within eight feet of the stove.

Single venting

Each ‘airtight’ stove requires its own flue. If an airtight

stove is vented to a flue that also serves an open fire-

place, or a leakier stove, it’s easier for the chimney draft

to pull air in through those channels and performance of

the stove suffers. Imagine a vacuum cleaner with a hole in

the hose to understand the effect here. In some cases the

other appliance can even cause a negative draft through

the stove, and result in a dangerous draft reversal.

creosote

Creosote is a by-product of slow wood-burning. It’s an

organic tar that can condense in the flue if it is present in

the exhaust, slow-moving, and cools to less than 90°F

(130°C). Condensed creosote is volatile, and can gener-

ate chimney fires if it gets hot enough. All the features that

affect chimney draft also affect creosote condensation

- so use whatever combination of installation features and

operational steps that will encourage good draft and mini-

mize creosote production.

Because letting the exhaust cool off and slow down is one

of the keys to creosote accumulation, it makes sense to

line a chimney to match the stove’s outlet size, for safety

reasons as well as performance. Consult a qualified

installer and check local and national codes for recom-

mended chimney sizing.

Fuel

Even the best stove installation will not perform well with

poor fuel. The best fuel is hardwood that has air-dried 1-

18 months. Softwood burns, but not as long as hardwood.

‘Green’ wood has a lot of moisture in it; it will burn, but

some of the heat potential is used to boil the extra mois-

ture from the wood. This reduces the amount of heat that

reaches your home and can contribute to a creosote prob-

lem. There are moisture meters available for firewood; you

can also judge your wood by its appearance and weight. If

you get it green, lift a piece and get a sense of its weight;

it can lose a third or more of its weight as it dries. Also look

at the ends of a log; as it dries it shrinks and often cracks.

The more weathered and cracked a piece is, the drier it is.

Dry wood burns readily with a good chimney draft. But

with modern stoves, wood can be too dry and too vola-

tile. Smoke and combustible gases can ‘gas out’ from the

wood quickly and densely enough to overload the combus-

tion system. If you hear a rumbling or roaring noise (like a

propane torch) from the stove, that is a sign that the stove

is overfiring.

back-puffing

Back-puffing results when the fire produces volatile gases

faster than the chimney draft pulls them out of the firebox.

The gases back up in the firebox until they are concen-

trated enough and hot enough to ignite. If your stove back-

puffs, the stove needs to cool down. You should open the

damper to let the smoke rise to the flue more quickly, allow

more air into the firebox, avoid big loads of firewood and

check that the wood moisture is not too low.

Draft Testing

An easy way to test your chimney draft is to close the

stove’s damper, wait a few minutes to let the airflow stabi-

lize, then see whether you can vary the strength of the fire

by swinging the air control open and closed. Results are

not always instant; you may need to wait a few minutes for

a change in the air control setting to have an effect on the

fire. If there’s no change, then the draft isn’t strong enough

yet to let you close the damper, and you’ll need to open it

for awhile longer and manage the fire with the air inlet until

the draft strengthens. If you keep track of your burning

habits and relate them to their effects on the stove’s opera-

tion, you’ll be rewarded with good performance and a safe

system.

Negative pressure

Good draft also depends on a supply of air to the stove;

a chimney can’t pull in more air than is available to it.

Sluggish draft results when a house is tight enough to

prevent the ready flow of air to the stove, or by competition

between the stove and other equipment that sends indoor

air outside - especially power-driven equipment like range

hoods, clothes dryers, etc. If the chimney draws well with

all other equipment turned off (or sealed, in the case of

fireplaces and/or other stoves), then you simply need to

be careful with timing the use of the other air consuming

equipment. If you need to crack a nearby window or door

to enable the chimney to flow well, it may be a good idea

to install an outside-air intake to bring combustion air di-

rectly to the stove. An outside air kit is available to connect

the stove directly to a source of outdoor combustion air.

In many cases, local or national codes require the installa-

tion of permanently open air vents, particularly with larger

appliances (i.e. above 5 kW). Refer to these codes to

determine specific requirements for your installation.

conclusion

Wood-burning is an art rather than a science. Once the

stove and chimney system are in place, you can only

vary your technique, mostly your timing, to achieve good

results. If you keep track of your burning habits and relate

them to their effects on the stove’s operation, you’ll be

rewarded with good performance and year of reliable heat-

ing.