26

73D0024

KHLDV Series Gas Fireplace

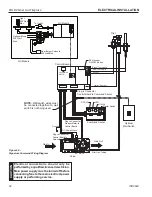

MILLIVoLt - optIonaL Fan/BLower SySteM

FP2137

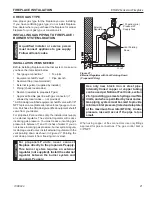

blower access plates

Clip

Firebox

Wall

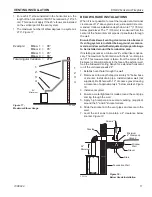

Figure 35 -

Blower Access Covers

FP2137

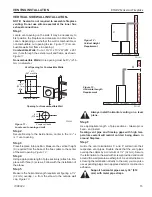

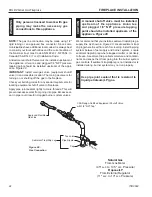

Figure 34 -

Blower Wiring Diagram

Junction Box

Blower

Rheostat

T-Stat Sensor

Right

Blower

Left

Blower

White

Black

Hi-Temp

Black

Black

Hi-Temp

Black

Black

FP2135

blower wiring diagram

Blue

Blue

Boîte de jonction

Ventilateur

Rheostat

Capteur t-stat

Ventilateur

droit

Ventilateur

gauche

Blanc

Noir

Hi-Temp

Noir

Noir

Hi-Temp

Noir

Noir

Bleu

Bleu

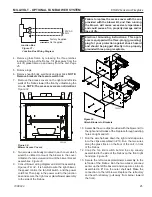

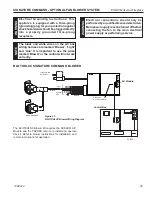

14. Replace side panels attached to the glass frame

assembly with the louvered side panels provided with

the blower kit by unfastening the four nuts for each

cover door. (Do not overtighten or stud may break

off.) Use three metal clip screws provided with kit to

secure the wire assembly in the front beneath the

access cover.

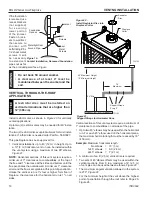

Figure 36

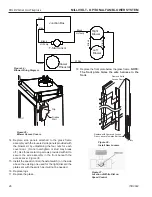

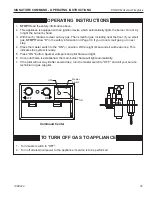

15. Install the speed control (rheostat switch) on the side

above the existing one used for the light (discard the

plate sent with the switch as it will not be needed.

16. Replace logs.

17. Replace the glass.

18. Replace the front plate below the glass frame.

note:

the front plate hides the wire harness in the

front.

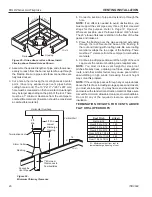

Figure 37 -

Location of White Dial on

Speed Control

Figure 36 -

Install New Louvers

FP2234

install louvers

1/09

Remove Solid

Access Door

Replace with Louvered Access

Door, Louvers Towards Bottom

FP2234