11

Merrimack Large Insert

30004671

How do you know if your draft is excessively high or low?

Symptoms of too much draft include an uncontrollable

burn or glowing-red cast iron. A sign of inadequate draft is

smoke leaking into the room through the stove or chimney

connector joints, low heat, and dirty glass.

In some newer homes that are well-insulated and weather-

tight, poor draft may result from insufficient air in the

house. In such instances, an open window near the stove

on the windward side of the house will provide the fresh

air needed.

When first using the stove, keep track of the settings of

the air controls. You will quickly find that a specific setting

will give you a fixed amount of heat. It may take a week

or two to determine the amount of heat and the length of

burn you should expect from various settings.

Most installations do not require a large amount of com-

bustion air, especially if adequate draft is available.

Do

not for any reason attempt to increase the firing of

your heater by altering the air control adjustment

range outlined in these directions.

Use the following primary air control lever and fan speed

control lever settings as a starting point to help determine

the best settings for your installation.

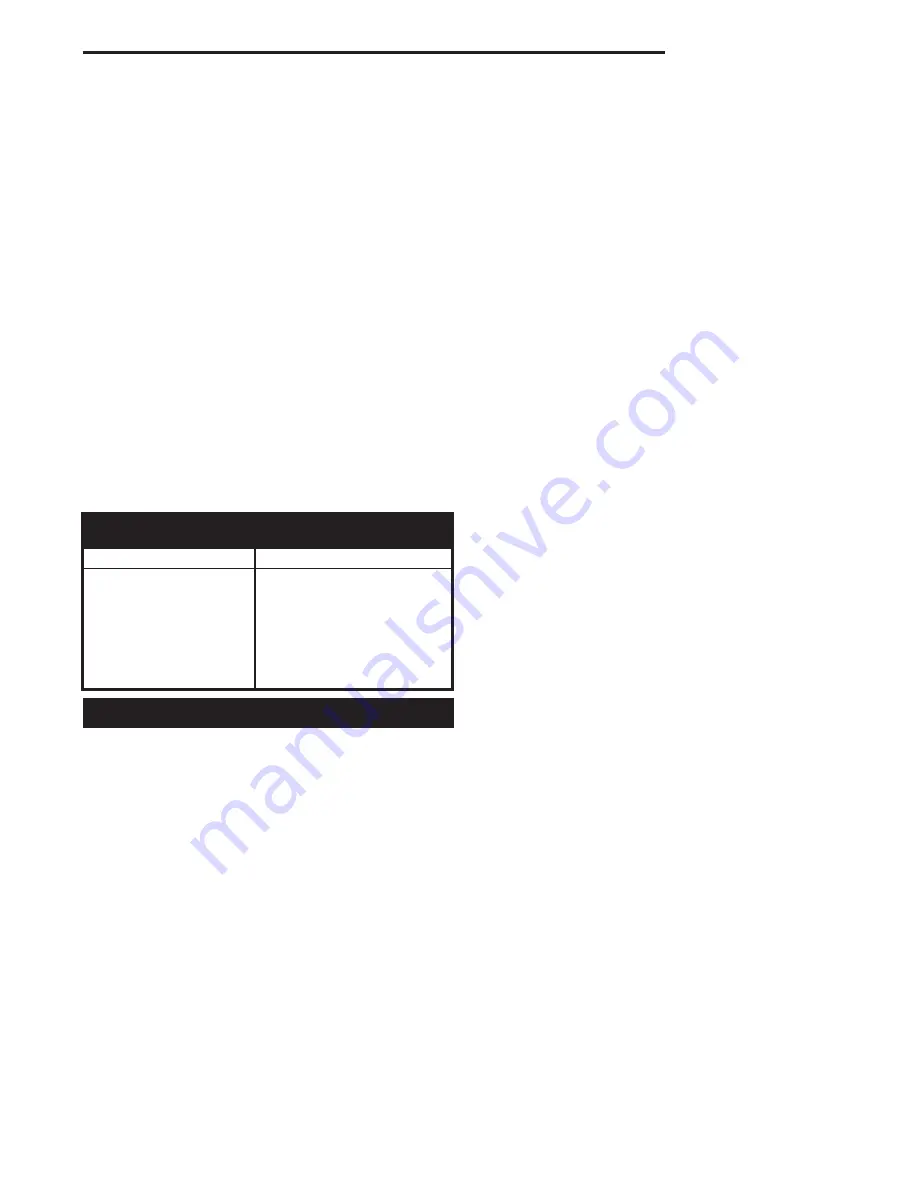

Merrimack Large Insert control Settings

primary air

air circulation

burn

control

Fan

control

Rate

Setting

Speed

position

High

Fully left

High

Horizontal

Medium

1” from

Low

Turn clockwise

full right

Low

Fully right

Off Turn counterclockwise

Starting and Maintaining a wood Fire

burn solid wood fuel only in the Merrimack Large In-

sert, and burn it directly on the grate. Do not elevate

the fuel. Do not burn coal or other fuels.

Cast iron is a superior material for solid fuel stoves but

it must be treated with respect. It is extremely strong,

but can be broken with a sharp blow from a hammer or

from the thermal shock of rapid and extreme temperature

changes. It is important to temper the cast iron plates with

an initial series of 3-4 break-in fires. The plates expand

and contract with changes in temperature. Minimize

thermal stress by allowing the plates to adjust gradually

during the break-in fires by following Steps 1-3 on the

following page.

waRNINg: operate your Merrimack Large Insert only

with the door fully closed. If the door is left partially

open, gas and flame may be drawn out of the fireplace

opening, creating risks of both fire and smoke.

Follow these guidelines as you start and maintain the

fire, and remove the ashes. Prior to starting a fire with a

cold stove, it is recommended to clear the lower primary

air hole located at the nose of the front brick. To do this,

remove the andiron and lift out the front refractory brick.

Sweep any ash accumulation out of the air slot. Keeping

this slot clear of ash will ensure better performance.

1. Open the primary air control fully.

. Lay several sheets of crumpled newspaper in the

bottom. Place on the paper six or eight pieces of dry,

finely-split kindling. On the kindling lay two or three

larger sticks of split dry wood approximately 1-” (5-

50 mm).

Do not use chemicals or fluids to start the fire. Do not

burn garbage or flammable fluids such as gasoline,

naptha, or engine oil. also, never use gasoline-type

lantern fuel, kerosene, charcoal lighter fluid, or similar

liquids to start or “freshen up” a fire in this heater.

keep all such liquids well away from the heater while

it is in use.

3. Light the newspaper and close the door. Gradually

build up the fire by adding a few 3-5” (76 -17 mm)

diameter splits.

If this is your initial break-in fire, let the fire burn brightly,

but not to excess. Control the fire’s intensity by adjusting

the air control lever. After an hour or so stop adding wood

so that the fire dies out gradually.

For ongoing operation after the initial break-in, continue

to add a few sticks at a time of a progressively larger size.

Be sure to keep the fuel load behind the front grate bar

at all times. Continue until you have a live ember bed at

least 3-4” (76 - 10 mm) deep. This may take an hour or

longer, particularly when the Merrimack Large Insert is

vented to an exterior masonry chimney or when you are

just starting a fire.

You’ll soon find that the insert is

hoT whILe IN opeRa-

TIoN! keep chILDReN, cLoThINg, aND FURNITURe

away. coNTacT May caUSe SkIN bURNS.

NoTe:

Some chimneys need to be “primed,” or warmed

up, before they will draw sufficiently to start a fire. To cor-

rect this situation, roll up a couple pieces of newspaper,

place them on top of the kindling and toward the back of

the stove, light them, and close the doors. This should

heat the chimney enough to initiate a draft.

Once the draft is established, open the front door and light

the rest of the fuel from the bottom. Do not light the main

bed of fuel until the chimney begins drawing, and repeat

the procedure as often as necessary if the initial attempt

is unsuccessful.