13

Merrimack Large Insert

30004671

Maintenance

keep your Merrimack Large Insert

Looking New and working Its best

care of the cast Iron Surface

An occasional dusting with a dry rag will keep the

painted cast iron of your Merrimack Large Insert looking

new.

If the paint needs retouching, first allow the surface to

cool completely. Mask glass, trim parts and enamelled

areas. Wire-brush those areas to be painted. Touch-up

with high temperature stove paint available from your

local dealer. Apply the paint sparingly. Two light coats

are better than one heavy one.

care of the porcelain enamel Surface

Use a soft brush as necessary. Do not use water or

other liquids on your Merrimack Large Insert. Finger-

prints usually can be buffed off porcelain enamel with

a dry, soft cloth. If marks remain, allow the Merrimack

Large Insert to cool completely, then buff with a slightly

damp, soft cloth. Dry completely before starting a fire to

avoid streaking.

Never use abrasives or harsh chemical cleaners on

the porcelain enamel finish; the enamel may scratch

and expose the cast iron, which can then stain or

rust. If you must remove spills or stains from porcelain

surfaces, make sure the fire is out and the Merrimack

Large Insert has cooled completely before cleaning.

Use a kitchen appliance cleaner and/or polish specifi-

cally formulated for enamel surfaces. Apply the cleaner

sparingly with a soft cloth, and buff away all traces.

cleaning the glass

The Merrimack Large Insert glass system requires a

minimum amount of cleaning. Most carbon deposits

that accumulate will burn off during hot fires.

Ash residue that accumulates on the glass should be

removed periodically to prevent etching. To clean the

glass, use the following procedure.

•

Be sure the glass is completely cool.

•

Cleaning with water will work in most cases. Use

a glass cleaner especially made for this purpose

only if deposits are specially heavy. (If heavy

deposits are a frequent occurrence, however,

evaluate your operating techniques.) Do not use

abrasive cleaners.

•

Rinse the glass thoroughly.

•

Dry the glass completely.

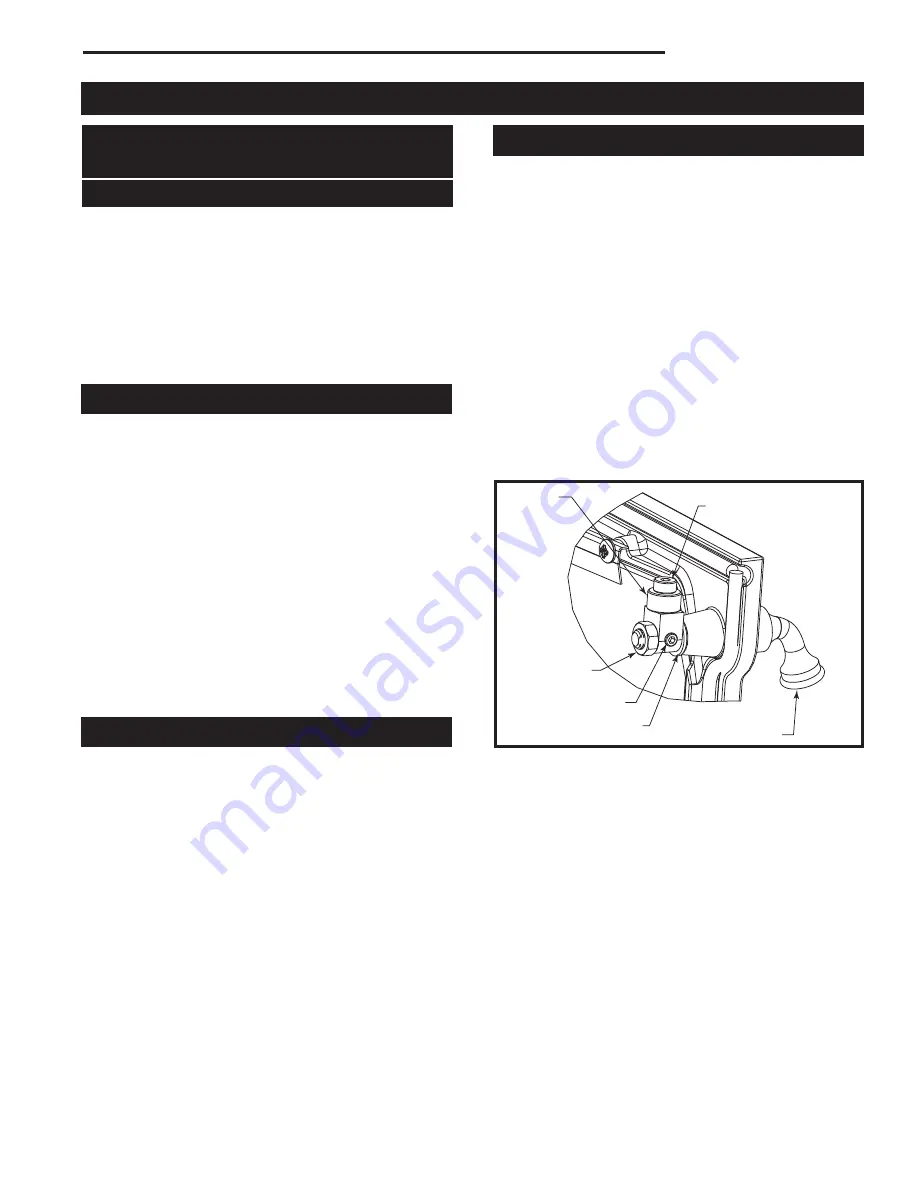

adjust the Door Latch periodically

The front door of the Merrimack Large Insert should

close securely to prevent accidental opening and

should close tightly to prevent air from leaking into the

fire chamber. The door handle will be positioned verti-

cally when the door is closed.

Over a period of time, the gasket around the door will

compress and the latch may need adjustment. To ad-

just the handle, follow this procedure:

1. Remove and retain the lock nut with a 9/16” wrench.

(Fig. 13)

. Loosen the set screw with a 1/8” Allen wrench.

3. Rotate the pawl 180°. Replace the lock nut. Tighten

the set screw.

4. Additional adjustment can be made by removing the

flat washer. Or any combination of washer removal

and/or pawl rotation.

Test the door seal. Close the door on a dollar bill and

attempt to pull it free. If the bill is freed with little re-

sistance, the gasket isn’t snug enough at that spot.

Continue to make small adjustments until the setting is

right.

If additional adjusting of the latch does not enable the

door to seal sufficiently in one area, try “adjusting” the

gasket in that area. Pack more cement or a smaller

diameter gasket into the channel beneath the gasket so

the main gasket is raised and makes contact with the

door frame. If this procedure doesn’t solve the problem,

replace the gasket. Instructions for gasket replacement

are given later in this section.

ST1154

door pawl

Roller

Lock Nut

Set Screw

Shoulder Screw

Handle Stub

ST1154

Fig. 13

Rotate pawl and/or remove flat washer to adjust

latch.

Flat Washer