9

Merrimack Large Insert

30004671

ST1163

merrimack mantel

Bracket and

Screws

Bracket and

Screws

ST1163

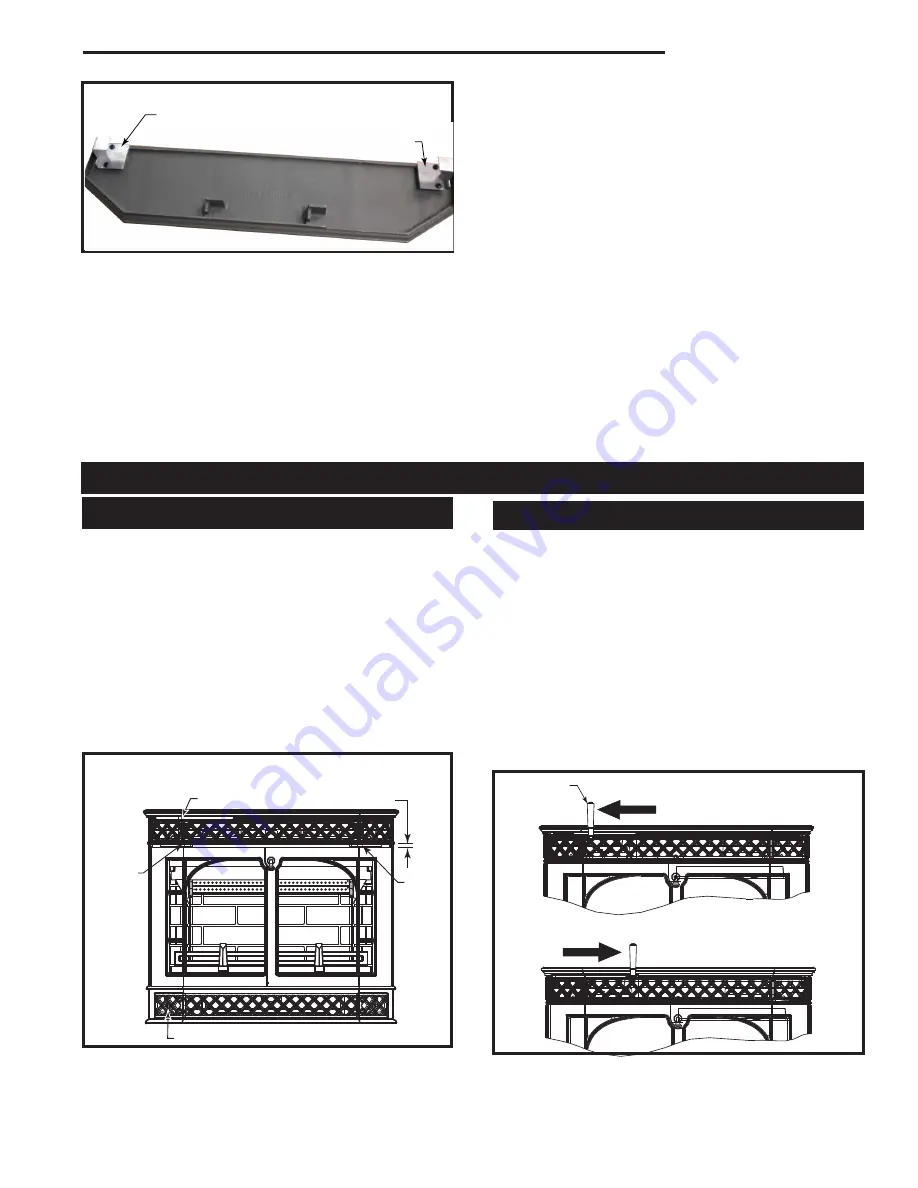

Fig. 8

Secure bracket to mantel with two () Philips screws.

the connector. Use the leveling screws at the front of

the Insert to adjust the level. Route the power cord to

the side nearest the power supply.

8. connect the Flue collar. :

From inside the stove,

reach up and pull the flue collar into place by lining up

the two 1/4” studs in the stove top. Care should be

taken to not disturb the gasket which seals the collar

to the top. Tighten the two 1/4” nuts.

•

Replace the stainless steel air tubes, if removed,

by sliding them first to the right and then into the

mating holes on the left. Secure these in place with

the stainless steel cotter pins.

•

Before installing the airwash manifold, replace the

fiber baffle board and ensure it slides all the way

to the back. There should be a tight fit between the

board and the iron sides of the stove.

•

Replace the front air tube and secure it in place with

the cotter pin.

9. connect the blower power cord to the power sup-

ply. Do NoT RoUTe The poweR coRD UNDeR

oR IN FRoNT oF The UNIT.

10.Install the supplied handle storage bracket by simply

sliding the flat end under the right or left side of the

stove. (Fig. 7)

This completes installation of your Merrimack Large

Insert.

operation

your Insert’s controls and what They Do

All Merrimack Large Insert controls are conveniently lo-

cated on the front. (Fig. 9)

Three controls regulate the performance of your Merrimack

Large Insert:

The

primary air control

supplies oxygen for the fire.

The variable-speed

fan control

, or rheostat, regulates

the warm air flow into the room.

An automatic setback control provides a high air setting

of restarting or reviving a fire after reloading and closes

automatically once the stove reaches operating tempera-

tures.

primary air control

A single air control regulates the amount of heat the fire

will produce and how long it will burn.

The

primary air control lever

is located on the upper left

side on the front of the insert. The lever regulates air for

starting, maintaining, and reviving the fire.

Generally, more air entering the stove makes the fire burn

hotter and faster, while less air prolongs the burn.

The Merrimack Large Insert’s air supply is increased when

the control lever is moved to the left, and decreased when

moved to the right. It may be set anywhere between the

two extremes, depending on the amount of heat desired.

(Fig. 10)

ST1157

primary air control

Air Control

Lever

ST1157

open -

control Lever to the Left

closed -

control Lever to the Right

Fig. 10

The air control lever controls the amount of air enter-

ing the firebox.

FP2493

Merrimack controls

Air Control Lever

Fan Speed Control (Behind louvre)

FP493

Fig. 9

Merrimack Large Insert controls.

Space Between

Doors and Upper

Lattice

Jacking

Screws

Jacking

Screws