8

Vermont Castings • Montpelier Medium Insert Installation & Operating Manual_R26 • 05/19

3-90-30004403

United States

Canada

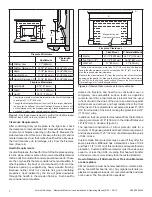

A*

16" (406 mm)

18" (460 mm)

B

8" (203 mm)

8" (203 mm)

C

44-3/4" (1137 mm)

44-3/4" (1137 mm)

Typically, thermal protection with the above dimensions will be required.

The equivalent of 1.25" (32 mm) of a material with a k-value 0.84 (or a

total

R-value of 1.49

) is necessary.

If the insert is elevated 8-1/2" (216 mm) or more above a combustible

hearth, thermal protection is not needed. However, spark and ember

protection is still necessary.

*If the insert is elevated 3" (76 mm) or more, with the optional hearth

extension, this dimension may be reduced to 16" (406 mm) (US only)

beyond which no thermal protection is necessary.

FP1095

hearth protection

2/08 djt

A

B

C

B

Figure 5

- Unless your fireplace and hearth are constructed over

a dirt floor (or unpainted concrete over dirt), you must use a floor

protector that satisfies the above requirements.

EXAMPLE:

The specified floor protector should be 1

1

⁄

4

"

thick material with k-factor of 0.84. The proposed alternate

is 4" brick with an r-factor of 0.2 over

1

⁄

4

" mineral board with

a k-factor of 0.29

Step a: Use formula above to convert specification to R-value:

Step b: Calculate R of proposed system.

4" brick of r = 0.2, therefore:

R

brick

= 0.2 x 4 = 0.8

1/8" mineral board of k = 0.29, therefore

R

mineralboard

= x 0.25 = 0.431

R

total

= R

brick

+ R

mineralboard

= 0.8 + 0.431 = 1.66

Step c: Compare proposed system Rtotal of 1.66 to specified

R of 1.49. Since proposed system Rtotal is greater than

required, the system is acceptable.

Definitions

R = x T = x 1.25 = 1.49

1

k

1

0.84

1

0.29

r = =

(ft

2

)(hr)(°F)

(Btu)(in)

1

k

(Btu)(ft)

(ft

2

)(hr)(°F)

K =

k = = K x 12

(Btu)(in)

(ft

2

)(hr)(°F)

R =

(ft

2

)(hr)(°F)

Btu

includes some form of thermal designation such as R-value

(thermal resistance) or k-factor (thermal conductivity).

Procedure:

1. Convert specifications to R-value:

i. R-value given - no conversion needed.

ii. k-factor is given with a required thickness (T) in inches:

iii. K-factor is given with a required thickness (T) in inches:

iv. r-factor is given with a required thickness (T) in inches:

R = r x T

2. Determine the R-value of the proposed alternate floor

protector:

i. Use the formula in Step 1 to convert values not

expressed as R.

ii. For multiple layers, add R-values of each layer to

determine overall R-value.

3. If the overall R-value of the system is greater than the

R-value of the specified floor protector, the alternate is

acceptable.

R = x T

1

K x 12

R = x T

1

k

Optional Surround Packages

Custom-made surround panels may be made from any

noncombustible material.

Vermont Castings offers both steel and cast iron Surround

panel kits, each in two sizes.

Georgian Cast Surround

Enclosure Area

30DVSGTKCB,

30DVSGTKB .................... 30-1/4" x 41 (768 x 1041 mm)

Mead Cast Surround:

MEAD3CB ........... 28-1/4" x 41-11/16" (718 x 1059 mm)

Caprice Cast Adjustable Profile Surround:

CAPCB ................................. 25" x 35" (635 x 889 mm )

Steel Surround:

LHE30SSB......................27" x 38-1/4" (686 X 972 mm)

LHE30SLB ..................... 28-1/4" x 41" (718 x 1041 mm)